VGC

TM

SEQUENTIAL VALVE GATE CONTROL

INSTRUCTION MANUAL

©INCOE® CORPORATION 2/2009

Pg.

www.incoe.com

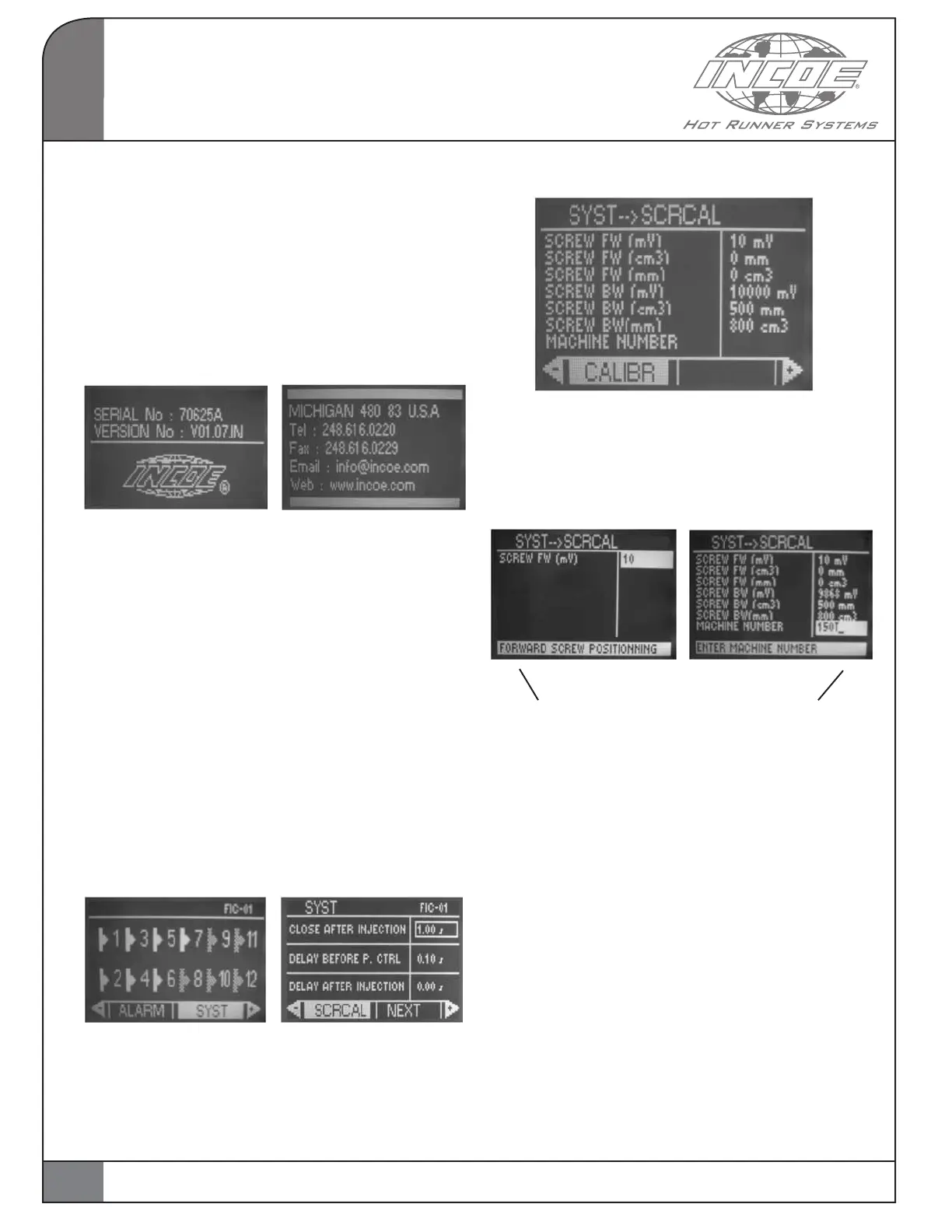

2.0 STARTING UP

Plant power 230V AC 50/60 Hz Single Phases cable

supplied.

Make sure that all connections to the backside

of the cabinet are correct (command signal,

alarms….). Switch the cabinet on with the 16A

circuit breaker.

The following pages appear after 5 seconds :

Important Notice: When the cabinet VGC Seq Valve

Gate Control is not in service, the A connector on

the backside of the cabinet must be disconnected

in order not to interfere with the signals from the

injection machine.

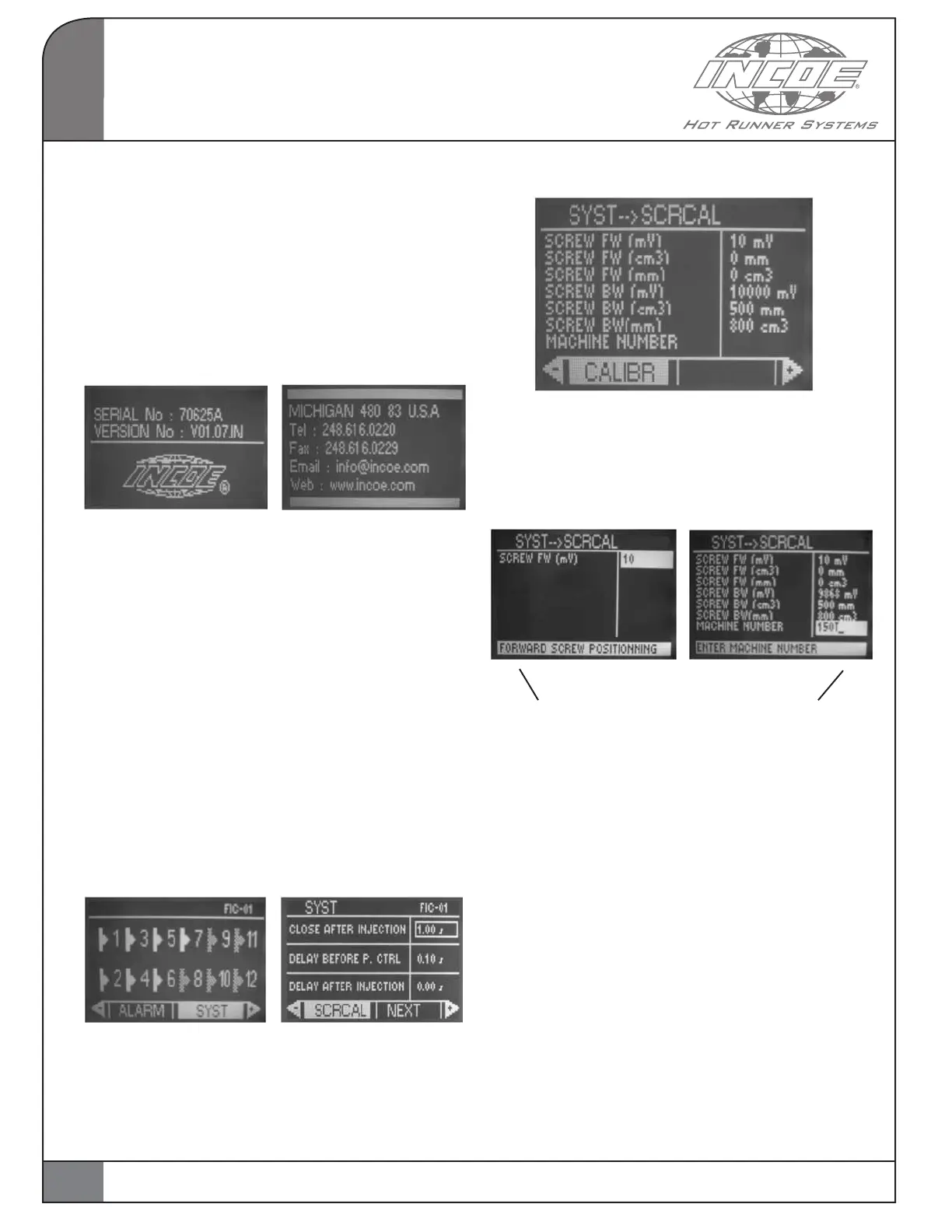

2.1 CALIBRATION

For proper use of the controller with the injection

molding machine, it is required to calibrate the

screw travel first.

To access the calibration page, simply select the

SYST function on white background, validate and

then select the SCRCAL function.

Select SCRCAL to calibrate the screw travel.

The following page is displayed.

Validate the function CALIBR to enter the calibration

process from this page and enter the calibration

values one after the other by moving the screw on

the injection machine.From this point, the process

must be brought to the end.

Guiding messages for the operator

Notice: The machine number is important information

to enter and to confirm which machine the calibration

process has been done on the controller.

Please note that if this controller is moved to another

machine, it must be recalibrated if you wish to use

the screw position signal for programming.

All words preceded by “MES.“ are values read

from the injection machine.

All words preceded by “VAL. “ are inputs made by

the operator.

OPERATION

2

8

Loading...

Loading...