24

Safety Precautions and Technical Details

DAA007EN - 11.05.2021

INSTRUCTIONS FOR SAFETY-CONSCIOUS WORK

4.1.3 Chuck and jaws

When a part is being placed in a chuck, there is a risk that fingers will be crushed

between the jaws and the part.

In general:

• The original mounting means of the clamping device manufacturer must be used

to mount the jaws.

• Mounting screws of the maximum possible length must be used.

• The mounting screws must be tightened with a torque spanner. The torque

must be selected according to the strength class of the screws or in conformity

with the specifications of the clamping device manufacturer.

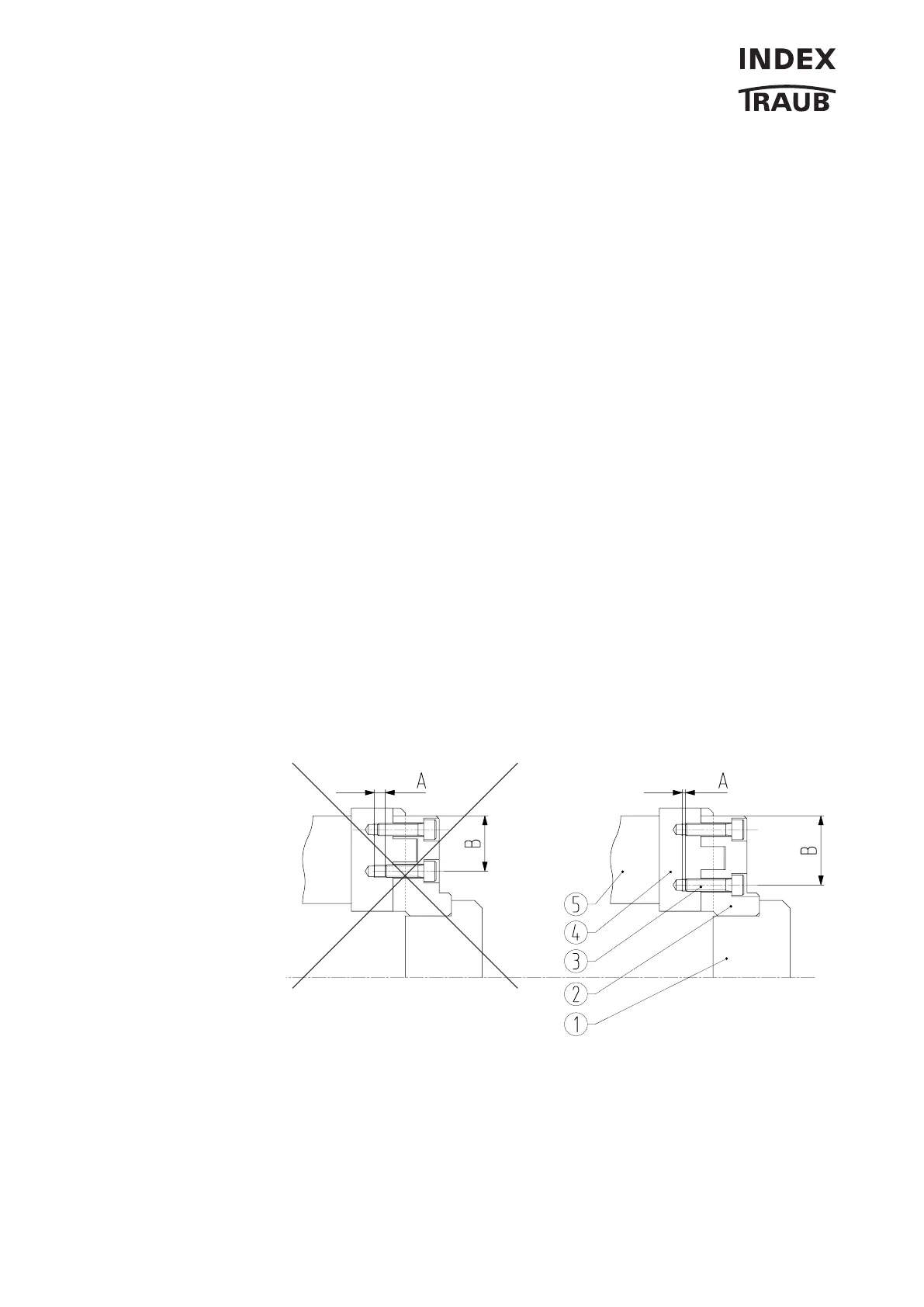

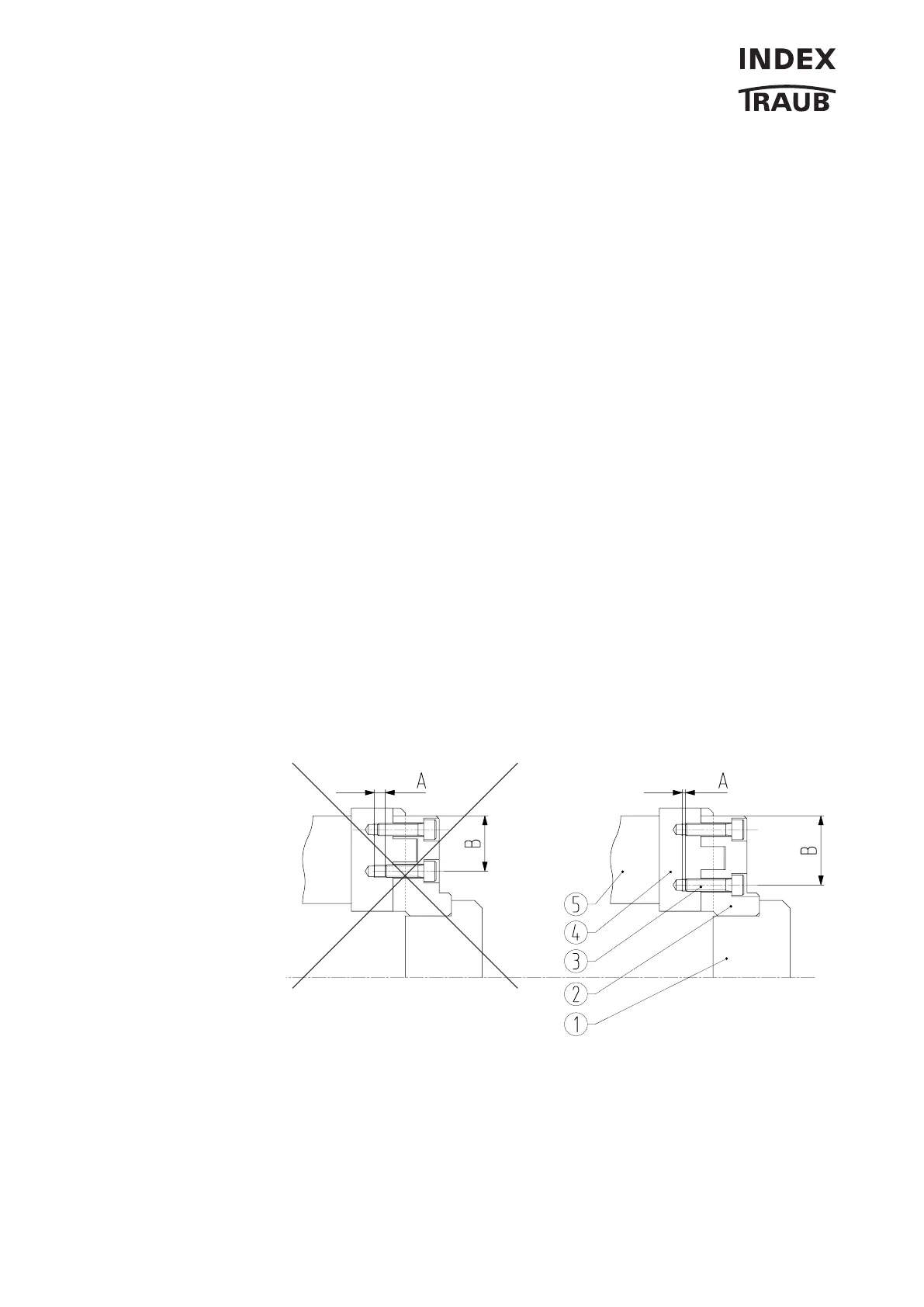

• Distance A (refer to drawing) between the end of the screw and the end of the

thread must not exceed 2 mm.

• Distance B (refer to drawing) must be as large as possible.

• Jaws with a maximum permissible rotational speed that is less than that of the

clamping device or the spindle must be marked in a clearly visible manner (e.g.,

with the maximum permissible rotational speed).

• The jaw stroke of each jaw must not exceed 4 mm. It must be ensured that the

jaws are shaped accordingly.

• For single-spindle lathes:

If a clamping travel of < 4 mm (0.163 in.) cannot be achieved, a suitable foot-op-

erated switch must be used.

• For multi-spindle lathes:

Manual loading and unloading in automatic mode is not allowed. For manual

loading and unloading in setup mode with clamping strokes > 4 mm, appropriate

safety measures must be taken.

Date: 17-Jun-20 Time: 13:53

Incorrect

Correct

1 Workpiece

2 Top jaw

3 Mounting screw

4 Base jaw

5 Chuck body

Loading...

Loading...