Chapter 3 – Inputs-Outputs

XtrapulsPac Installation Guide

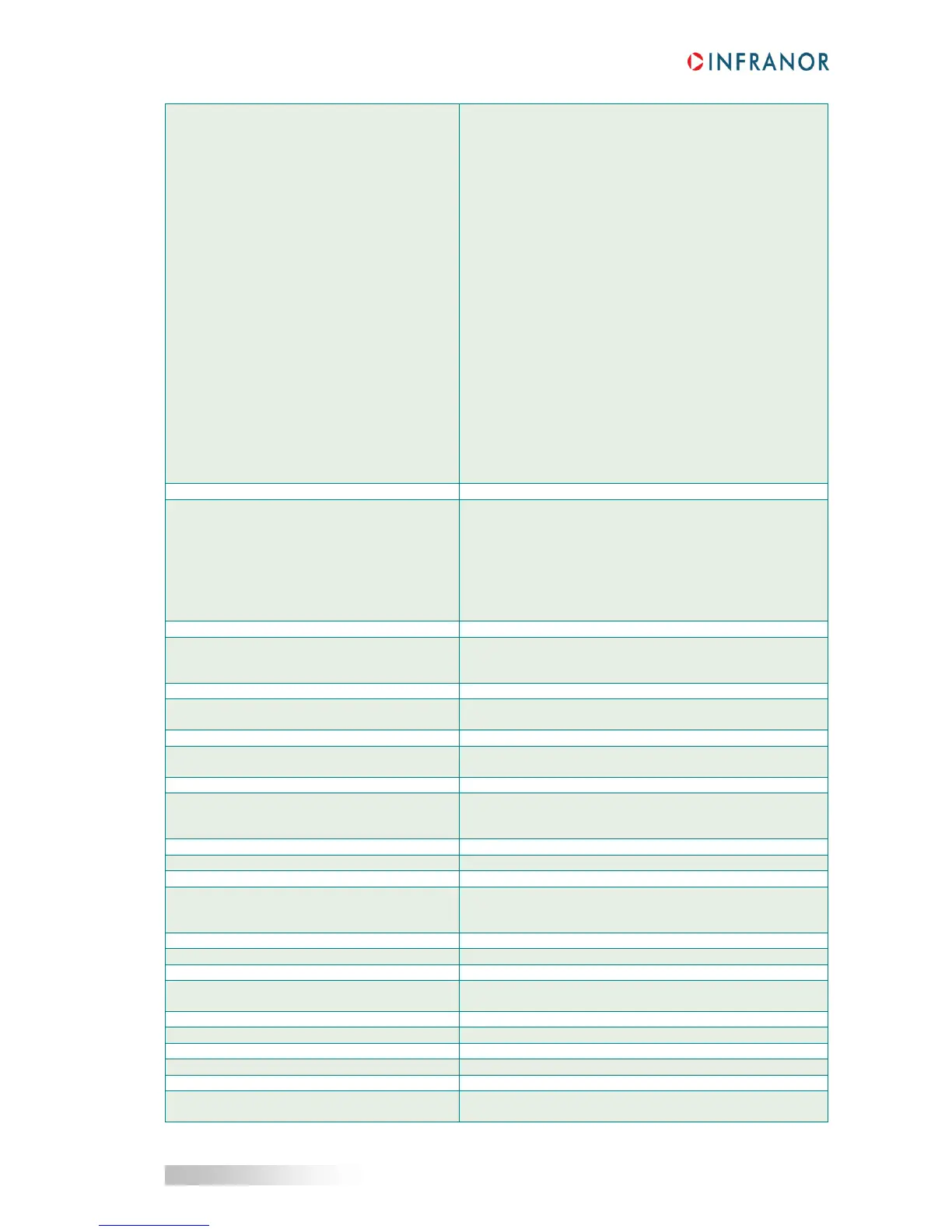

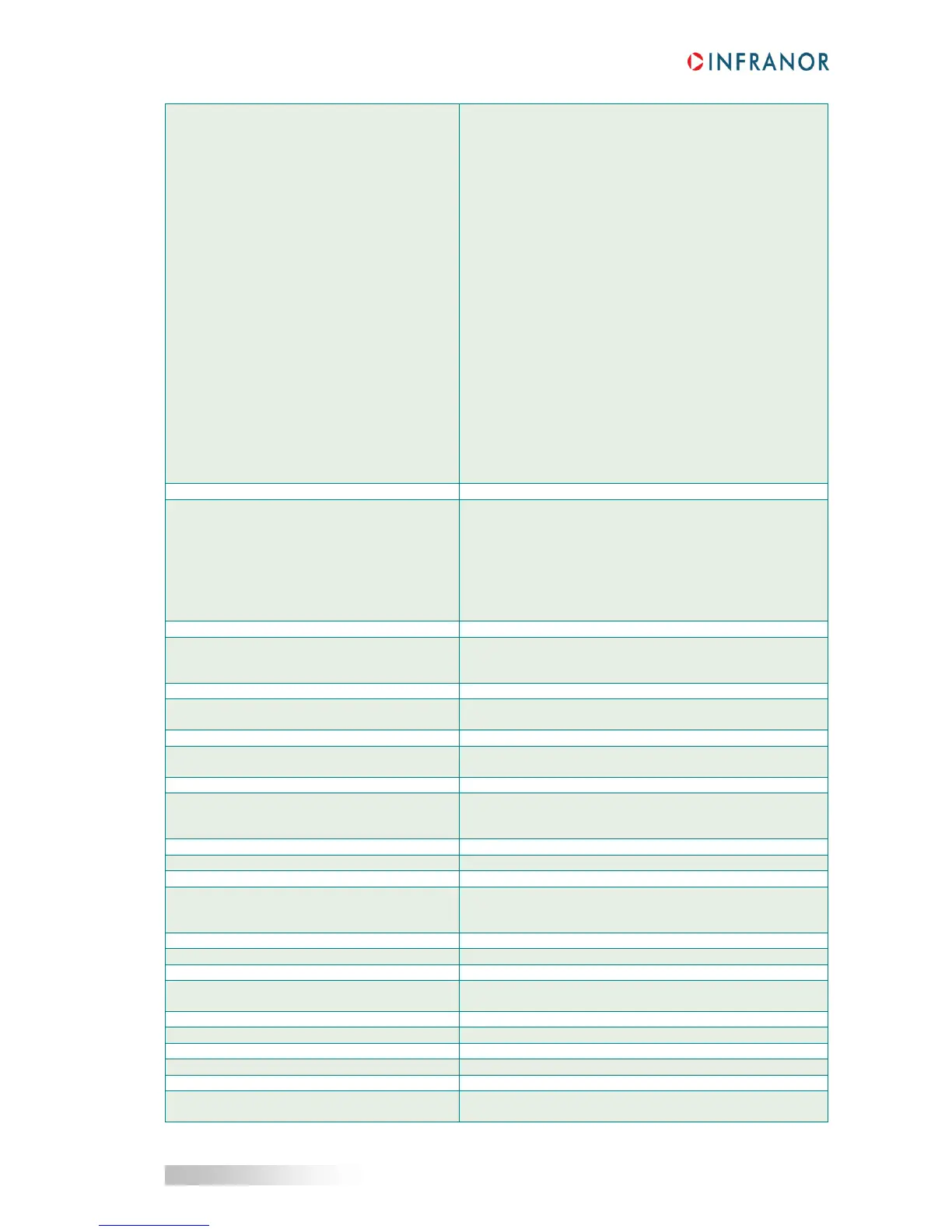

Software selectable:

Quadrature signals A & B + one Z marker pulse per revol.

Line receiver RS-422

Max. frequency of encoder pulses: 1 MHz

Resolution: 500 to 10

6

ppr

Incremental Sin/Cos encoder

Heidenhain 1 Vcc Sin/Cos type or compliant

Maximum signal frequency: 200 kHz

Resolution: 500 to 10

6

ppr

Interpolation factor: 256

Absolute single-turn Sin/Cos encoder

Heidenhain ERN 1085 or compliant

Maximum signal frequency: 200 kHz

Resolution: 512 to 2048 ppr

Interpolation factor: 256

Hiperface® standard with SinCos channels

Maximum signal frequency: 200 kHz

Resolution: 16 to 2048 ppr

Interpolation factor: 256

Hiperface DSL® standard

Software re-configuration of 2 logic inputs for stepper motor

emulation. 3 selectable channels:

- Optocoupled 24 V logic (max. pulse frequency = 10 kHz)

- Non optocoupled 5 V to 24 V

(max. pulse frequency = 50 kHz)

- RS422 differential receiver (max. pulse frequency = 1

MHz)

Resolution (steps per motor revolution): programmable.

5 V to 24 V positive logic voltage accepted

External HES supply voltage required if different from 5 V

HES sequence error detection

7 opto-isolated logic inputs

5 software configurable logic inputs

2 inputs dedicated to the STO (Safe Torque Off) function

"OptoMos" relay: output open if fault

Umax = 50 V, Imax = 300 mA

XtrapulsPac 230 V: not available / Use of the digital output

XtrapulsPac 400 V / 08 to 20 A: 24 V

DC

/ 1.5 A

XtrapulsPac 400 V / 45 to 200 A: 24 V

DC

/ 2.5 A

3 parameterizable logic outputs

Type PNP "high side" 24 V

DC

, max. 300 mA

2.5 V +/-2.5 V, resolution: 8 bit, load: 10 mA

Low-pass filter: 160 Hz, programmable output signal: all

objects can be mapped.

Front panel LEDs + diagnostic via serial link or CAN bus

Motor and application parameterization

Serial link RS-232 or

bus interface with CANopen® communication protocol

CANopen® Protocol (DS301, DSP402)

See EtherCAT® Fieldbus Interface manual

Drive adjustment to the motor (AUTO-PHASING)

Adjustment of the servo loops (AUTO-TUNING)

Loading...

Loading...