2 Wiring

- 7 -

2.3 Control Circuit Wire Size and Torque Specication

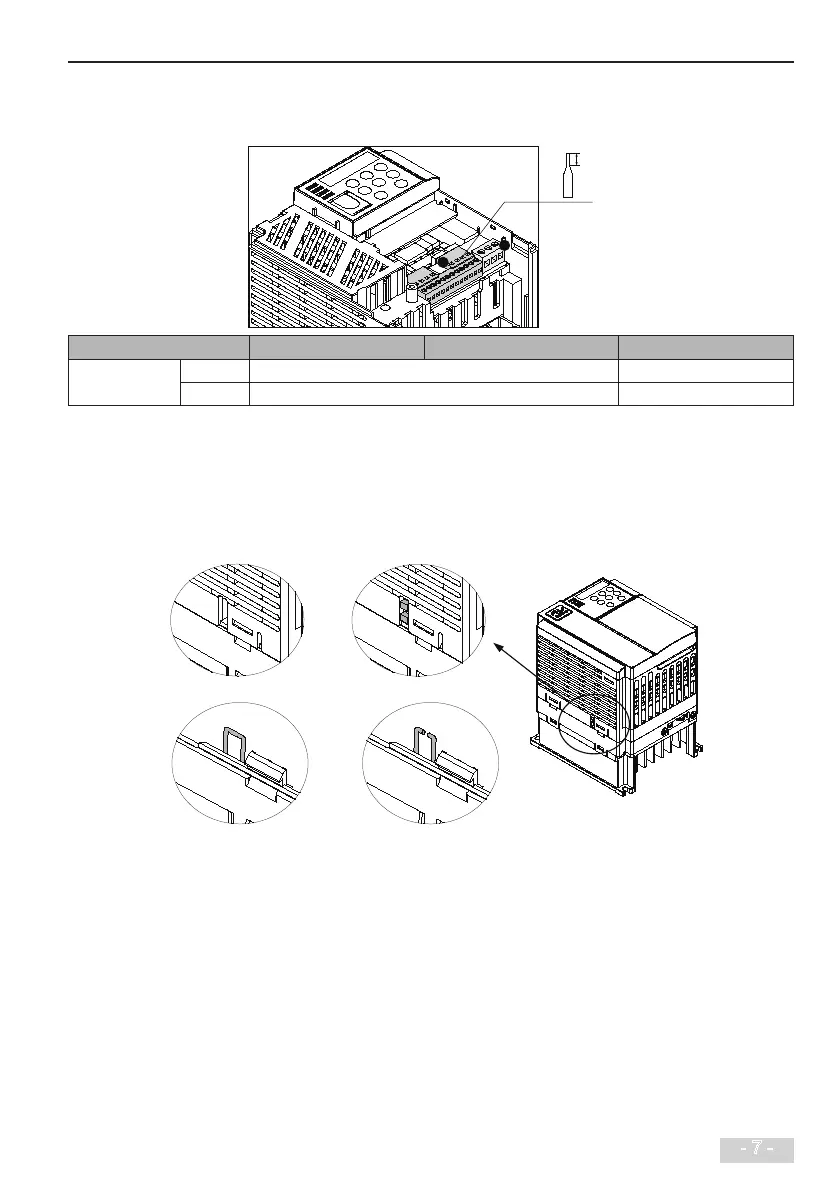

Please use a ferrule-type terminal with insulated sleeves� Prepare wire ends with insulated sleeves before connecting to the drive� See

the following gure for ferrule dimensions.

Terminal Block Single Wire (AWG/mm

2

) Twisted Wire (AWG/mm

2

) Tightening Torque (N·m)

Control circuit 1 AWG 24 to 18 (0�2 to 0�75 mm

2

) 0�2

2 AWG 24 to 18 (0�2 to 0�75 mm

2

) 0�51

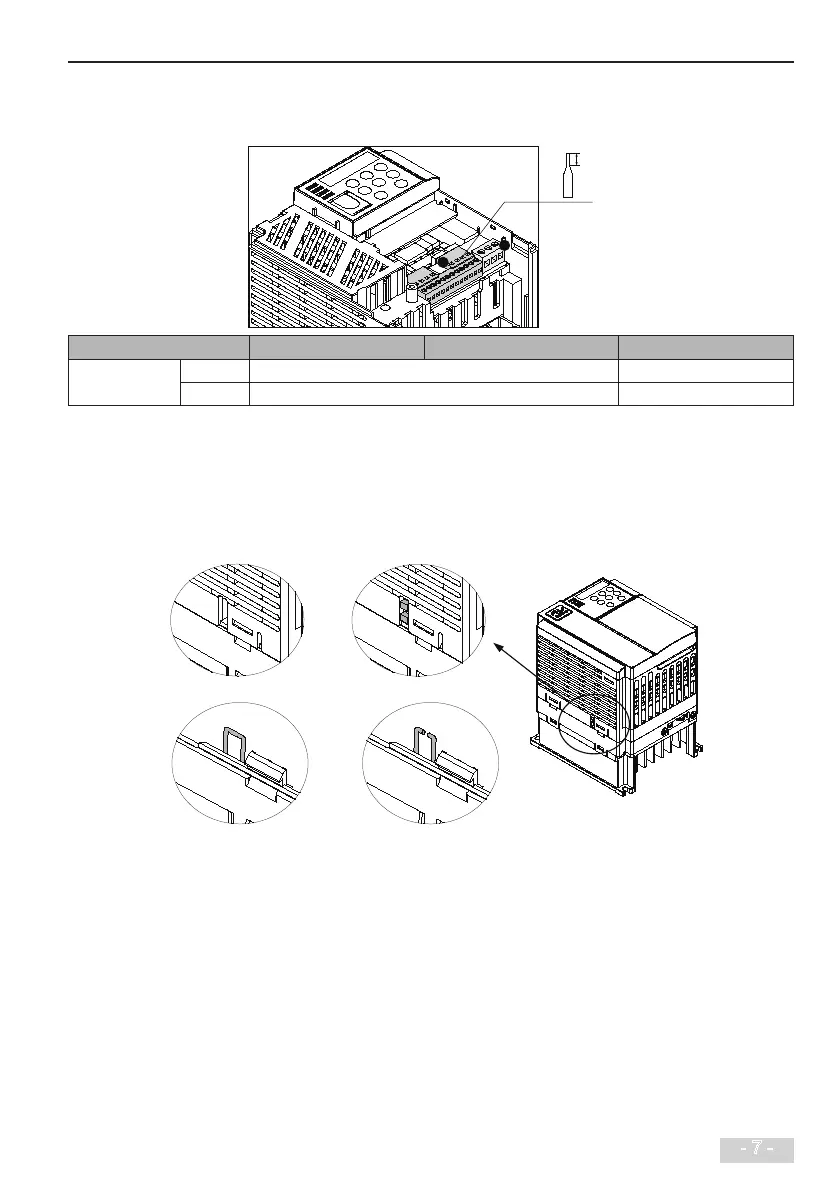

2�4 EMC Jumper/Screw

The AC drive has built-in safety capacitor� If the leakage current of the entire system is too large at power-on and the RCD acts, you can

cut the EMC jumper or remove the EMC screw to reduce leakage current to ground�

The position and cutting method of the EMC jumper is shown in the following gure.

Figure 2-1 EMC jumper position and cutting method of MD310T0�4B to MD310T5�5B

1� Snip off the two protective caps on the housing by using a cutting plier�

1

2

3

4

2� Then cut the exposed metal jumper�

Loading...

Loading...