Goodrive350-19 series VFD Operating

- 194 -

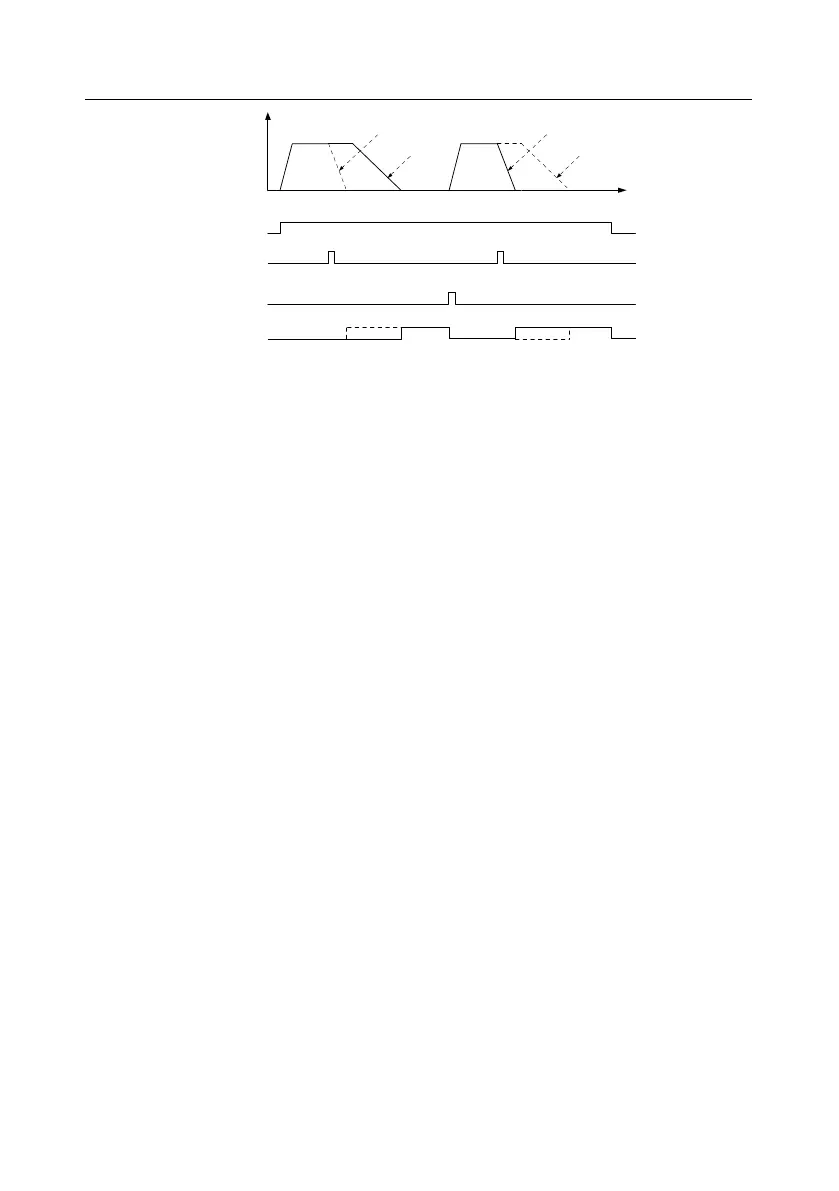

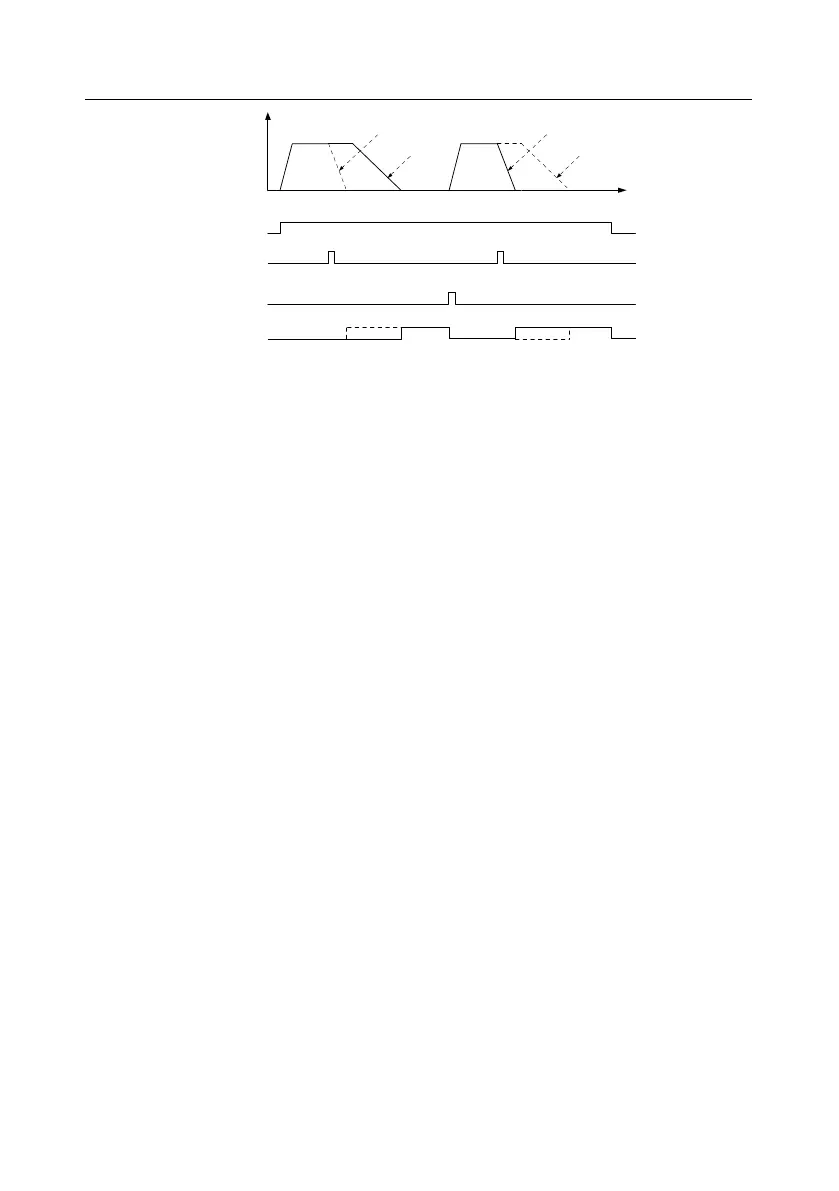

Directdeceleration positioning

Frequency

Running command

Photoelectric switch

arrival signal

Cyclic positioning

enable signal

Positioning completion

signal

Constant speed+

deceleration positioning

Directdeceleration positioning

Constant speed+

deceleration positioning

Time

Step 1–4: These four steps are the Same as the first four steps of the commissioning procedures for

closed-loop vector control, which aim to fulfill the control requirements of closed-loop vector control.

Step 5: Set P21.00=0021 to enable photoelectric switch positioning, the photoelectric switch signal

can be connected to S8 terminal only, and set P05.03=43, meanwhile, set P21.17, P21.11 and

P21.12 (set positioning displacement) based on actual needs; set P21.21 (deceleration time of

positioning), however, when present running speed is too fast or the set positioning displacement is

too small, the deceleration time of positioning will be invalid, and it will enter direct deceleration

positioning mode.

Step 6: Cyclic positioning

After positioning is done, the motor will stay in current position. You can set cyclic positioning through

input terminal function selection (55: enable cyclic digital positioning) in P05 group; when the terminal

receives cyclic positioning enable signal (pulse signal), the motor will continue running in the set

speed as per the speed mode and re-enter positioning state after encountering photoelectric switch.

Step 7: Hold positioning

The position loop gain during positioning is P21.03; while the position loop gain in

positioning-completion-hold state is P21.02. In order to keep sufficient position-hold force and ensure

no system oscillation occurred, adjust P03.00, P03.01, P20.05 and P21.02.

6.5.18 Fault handling

GD350-19 series VFD provides abundant information concerning fault handling for easy

maintenance.

Loading...

Loading...