10

B

E

F

A

C

G

D

ENT

ESC

L/H

L/H

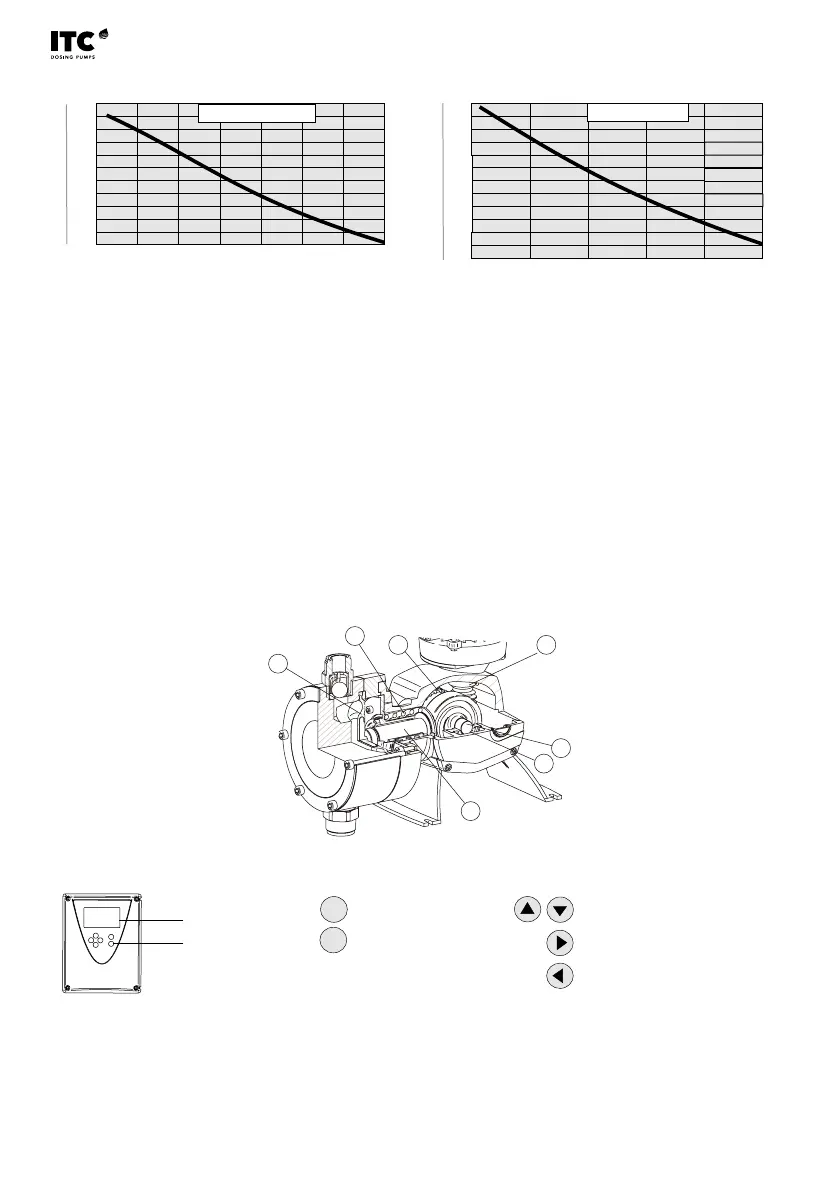

4325

Bars

1

1120-

1160-

1240-

1200-

l/h

GPH

270-

5843

29

72

PSI

14

1080-

280-

290-

300-

310-

320-

-

73-AC3D44-D163

1040-

l/h

620 -

660 -

700 -

43

2

1

GPH

170-

180-

190-

200-

210-

220-

5843

29

Bars

6

5

7

PSI

8772

101

14

740 -

780 -

820 -

73-AC3D43-D163

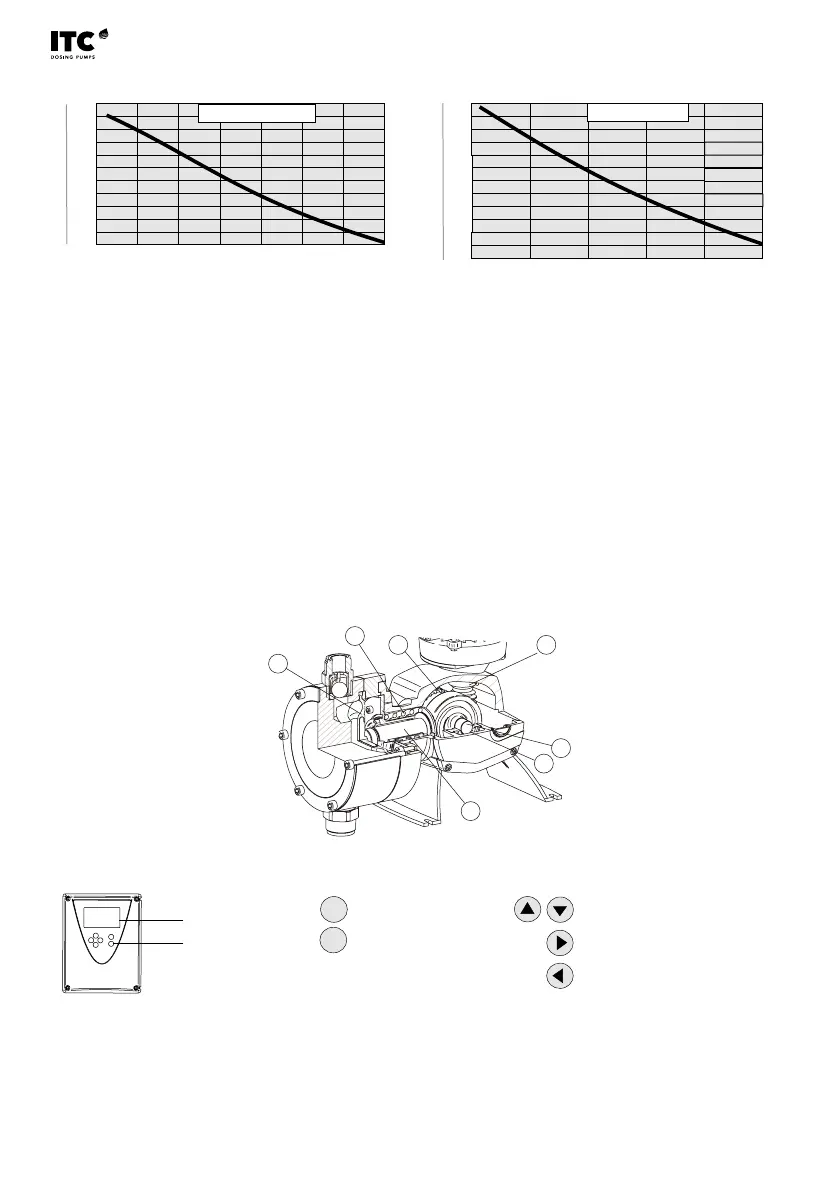

Conguration

4. OPERATION

The rotational motion of the motor is transmitted by the reducer, which consists of two major components,

the pinion (A) and the ring gear (B). The pinion and the ring gear are linked to a shaft with an eccentric

bearing (C) that pushes the shaft (D) which is throated to the diaphragm or the piston (E). The return

movement is made by a spring (F).

A high resolution encoder (G) checks the instantaneous position and speed and allows the Advanced

Control Unit to do a close loop adjustment for torque and rotation speed.

By changing the motor speed and depending on the operation mode selected in the Advanced Control

Unit, the dosing pump adjusts the ow to the required value within the range from 10 to 100% of the rated

ow.

EQUIPMENT DESCRIPTION

LCD screen

Keyboard

Conrm

Exit without

conrming

Increase/decrease value

Scroll left

Scroll right

Loading...

Loading...