ProPuls 320C

Operating manual Page 42

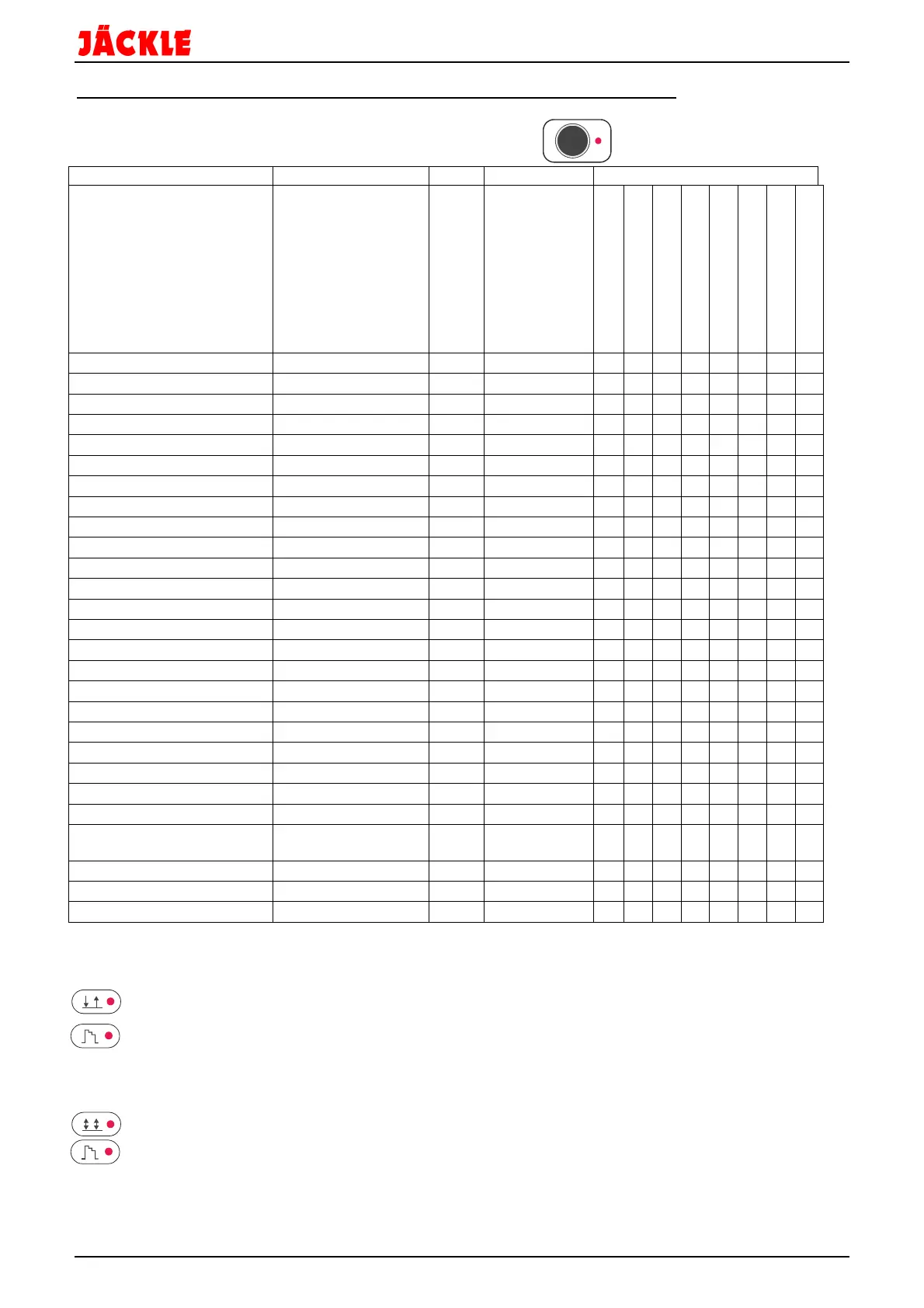

16.4 Fx / parameter description of the welding processes MIG/MAG:

The parameters can be called up using the Fx button and

changed with both dials.

Welding process

Function:

Selection with the left

Rotating knob (Pos. 2)

Display text

Basic settings

Range-

values

Selection

with the

right

rotating knob

(Pos. 8)

-Cycle

-cycle

C Crater

C Crater

C Crater + current I2

uble pulse

Gas pre flow time PRE GAS 0.1s 0.0 – 2.0s ● ● ● ● ● ● ●

●

Start speed START SPEED 0 -30 - +30 ● ● ● ● ● ● ●

●

Start pulse START PULS 0 -30 - +30 ● ● ● ● ● ● ●

●

Start current INIT CURRENT 20% -50 - +100% ● ● ●

Arc length Start INI. ARC L. 0 -30 - +30 ● ● ●

Crater Start time T. INIT CARTER 1.0s 0.0 – 2.0s ●

Start ramp INI SLOPE C. 1.0s 0.0 – 2.0s ● ● ●

End ramp FIN SLOPE C. 1.0s 0.0 – 8.0s ● ● ●

End current FINAL CURRENT -30% -100 - +50% ● ● ●

Arc length End FIN ARC L. 0 -30 - +30 ● ● ●

Crater End time T: FIN CRATER 0.0s 0.0 – 2.0s ●

Burn back time BURN BACK 0 -30 - +30 ● ● ● ● ● ● ●

●

Gas post flow time POST GAS 1.0s 0.0 – 10.0s ● ● ● ● ● ● ●

●

Current I2 Start ramp IN SLOPE CYC 0.05s

0.0 – 1.0s ●

Current I2 CYCLE CURR. 20% -99 - +100% ●

Arc length I2 CYCLE ARC L. 0 -30 - +30 ●

Current I2 End ramp FI SLOPE CYC 0.05s

0.0 – 1.0s ●

Double pulse Start ramp IN SLOPE DP 5.5s 0.5 – 100s

●

Double pulse current DPuls – CURR 50% -99 - +200%

●

Double pulse arc length DP Arc Len 0 -30 - +30

●

Double pulse balance DPuls - BAL. 0 -40 - +40

●

Double pulse frequency DPuls - FREQ. 2.7 0.1 – 5.0Hz

●

Double pulse End ramp FI SLOPE DP 5.1s 0,1 – 100s

●

Current rise rate Slope Job

100

A/s

5 – 500A/s ● ● ● ● ● ● ●

●

Spot time SPOT TIME 3.0s 0.0 – 20.0s ●

Welding ON time STITCH TIME 1.0s 0.1 – 8.0s ●

Pause (OFF) time STITCH PAUSE 1.0s 0.1 – 8.0s ●

•

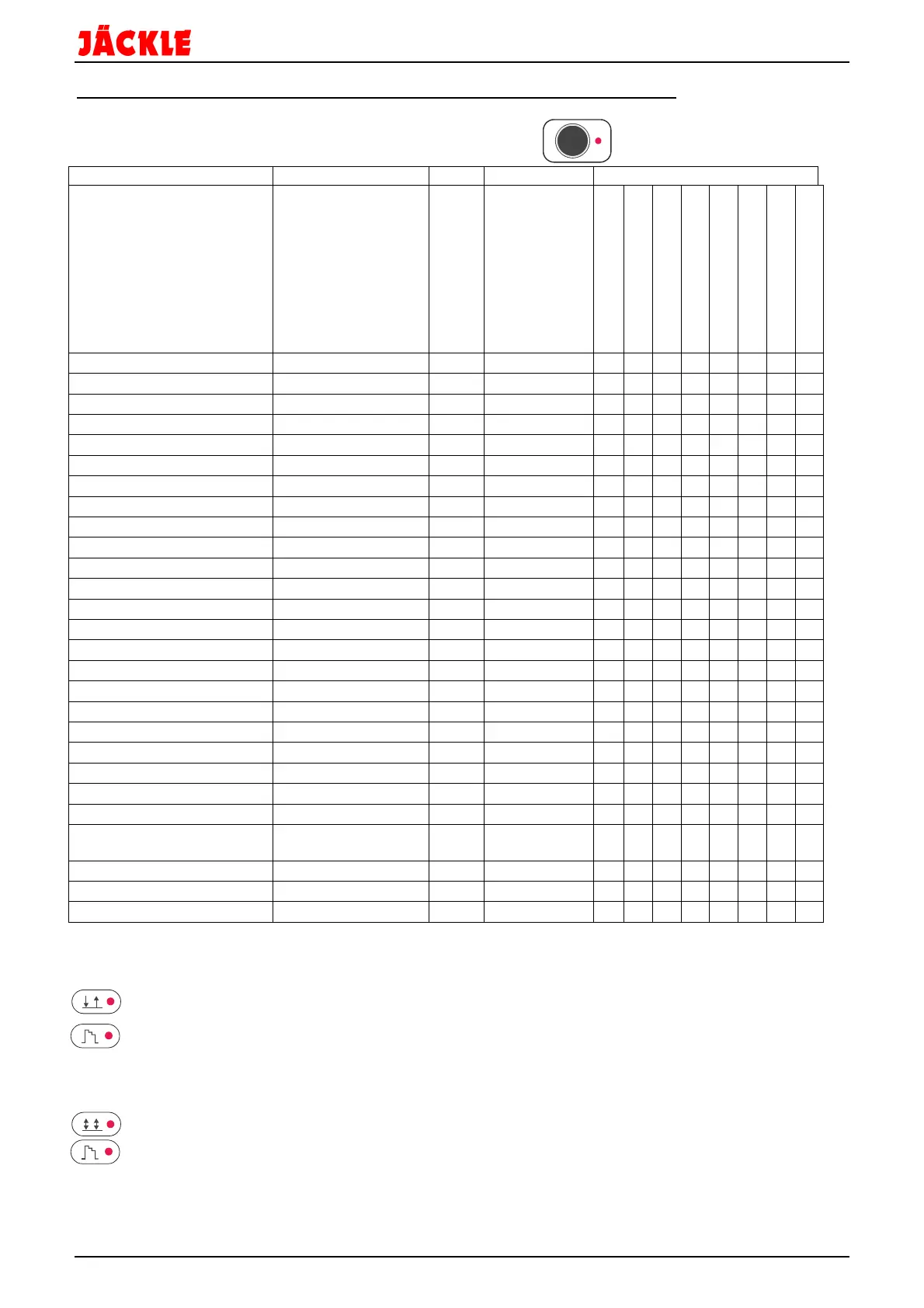

Standard crater program:

2 step:

The torch trigger is

pressed

and after the gas pre-flow time has elapsed, the arc is ignited with the

preset hot start current. After the hot-start time is finished, the current slopes down, over the preset start

ramp time, to the preset main welding current I1.

The torch trigger is

released

, and the current slopes down to the preset end crater-fill current, over the

end-crater ramp time. After the welding crater end time, the arc extinguishes.

After this, the shielding gas flows for the preset gas post flow time.

4 step:

The torch trigger is

pressed

and the arc is ignited with the preset hot-start current. The hot start current

is active all the time the trigger is pressed. When the trigger is released, the current slopes down, over

the preset start ramp time, to the main welding current I1, where it stays.

When the torch button is

pressed again

, the current slopes down over the end-crater ramp time, to the

preset end crater-fill current. The end crater-fill current is active all the time the trigger is pressed. and

stays at this level. The torch trigger

released

, and the arc is extenguished. After this, the shielding gas

flows for the preset gas post flow time.

F

X

Loading...

Loading...