ProPuls 320C

Operating manual Page 58

23. Trouble-shooting

Any remedial action to defective electrical equipment must be carried out by a

qualified electrician!

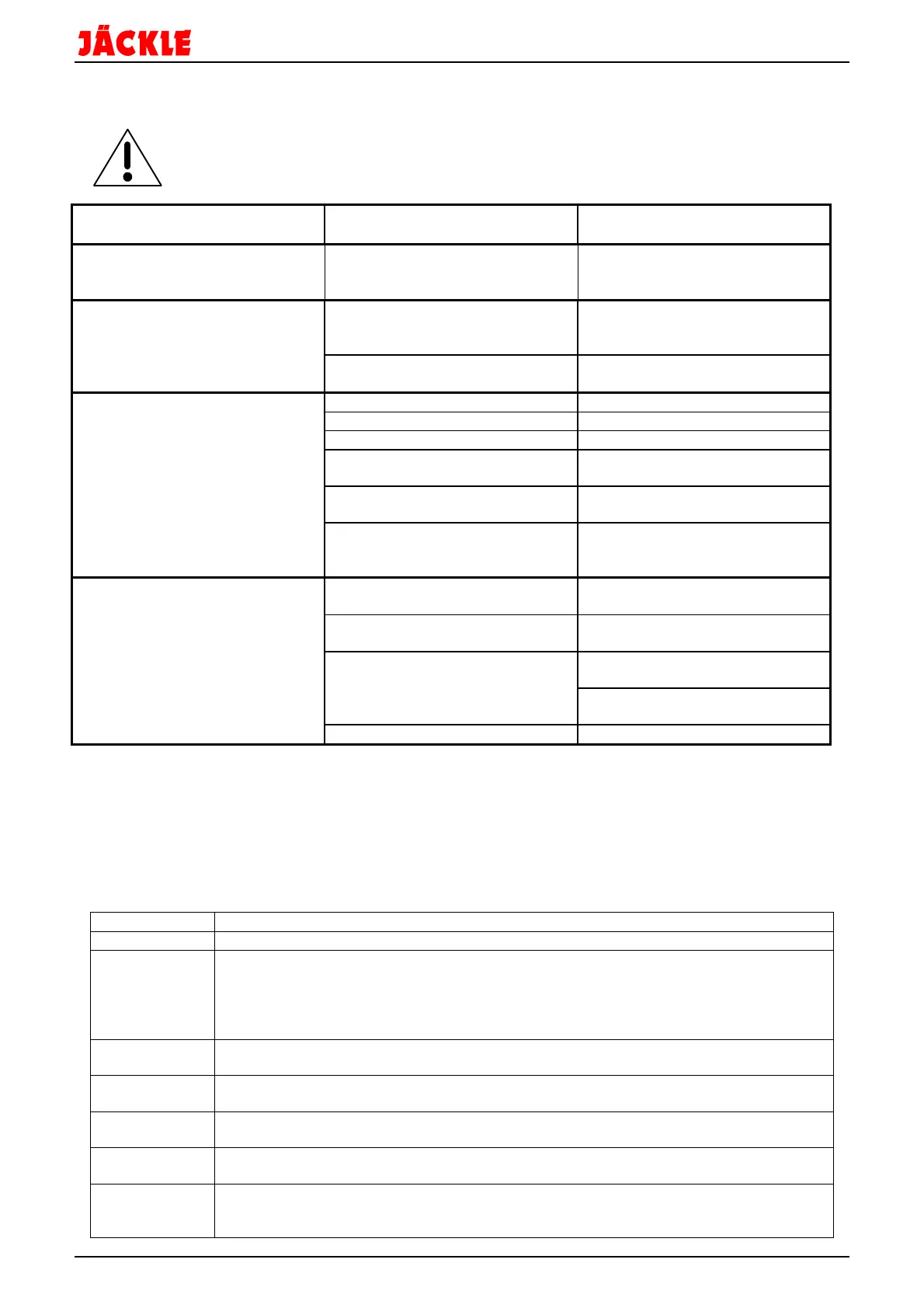

Malfunction/ Error Cause Remedy

mains voltage connected and loss of supply voltage Check mains fuse,

master switch in pos.´ON´/ Check mains cable

mains Control

is not lit

Wire buckling between wire feed

rollers and guide tube

excessive contact pressure of wire

feed rollers

see chapter 20 Wire feed

distance between wire feed rollers

and guide tube too far

check distance / realign guide tube

Irregular wire feed

bad uncoiling of wire

check / refit wire coil

wire-holding arbour runs heavily check wire-holding arbour

wrong wire feed roller see chapter 20 Wire feed

dirty / defective wire guide tube or

spiral

see chapter 20 Wire feed

clogged / defective current contact

tip

clean / exchange current contact

tip

dirty / rusty welding wire exchange welding wire

wire guide tube misaligned with

wire feed roller groove

see chapter 20 Wire feed

Porous weld seam work piece surface polluted (paint,

rust, oil, grease)

clean surface

no shielding gas (solenoid valve

not opening)

check / exchange solenoid valve

insufficient shielding gas check shielding gas at pressure

reducer

check gas line for leakage using

meter tube

gas nozzle polluted clean gas nozzle

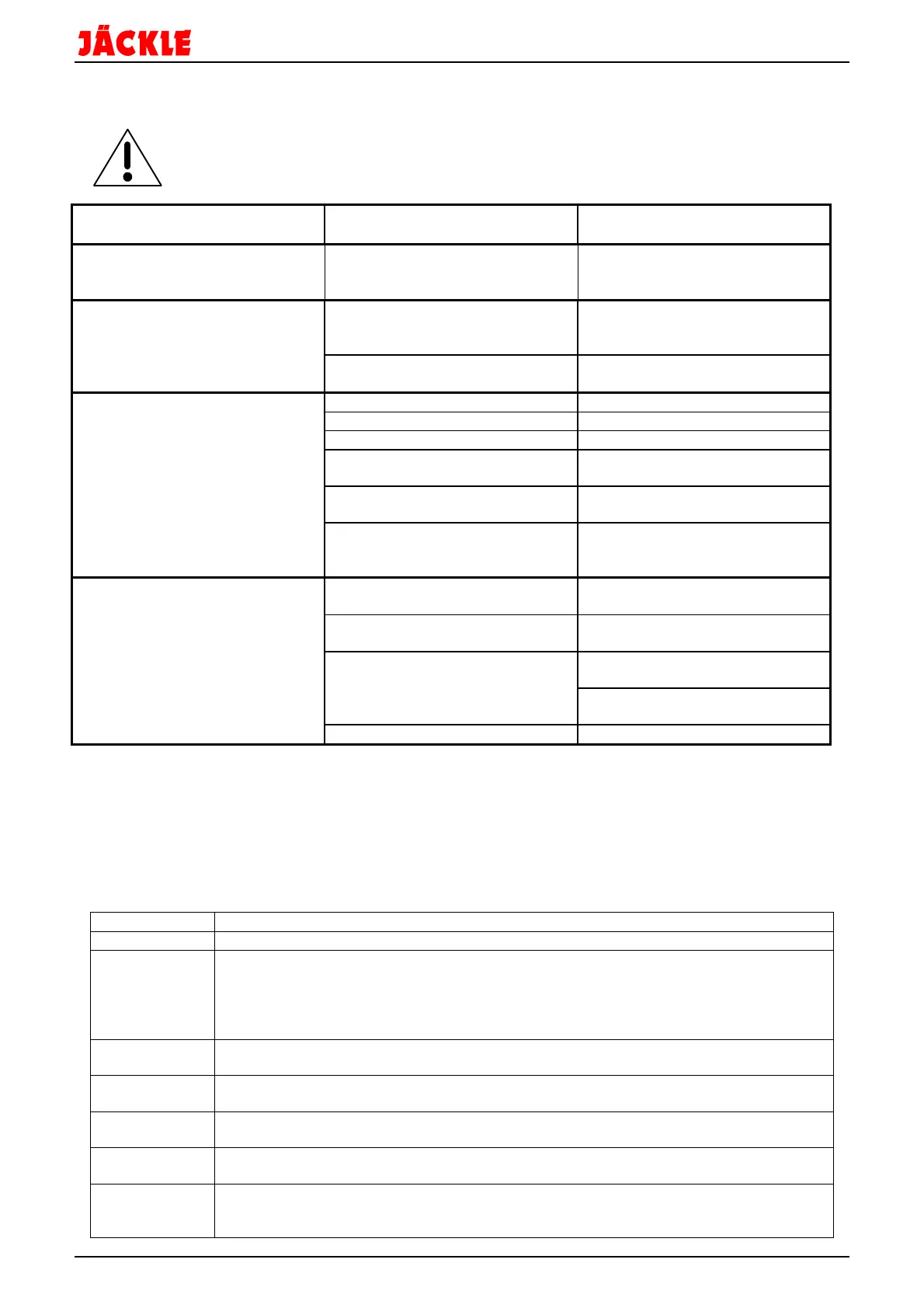

24. Automatic error diagnostics

In the case of error, error codes are shown in displays.

There are 2 types of errors:

- Error messages are deleted automatically (short-term errors)

- An error must be deleted by switching the welder on and off again (major fault / defect)

Error number Error description and possible diagnosis

E0.0 VOLTAGE SUPPLY ERROR

This error can only occur when switching on the unit, not during normal operation of the

welding unit.

This error is shown only on the display, but not saved in the error memory.

Deleting an error by switching the unit on and off again.

E0.1 REDUCED VOLTAGE AND OVERVOLTAGE

Error message deletes automatically

E0.2 OVERVOLTAGE

Error message deletes automatically

E0.3 REDUCED VOLTAGE

Error message deletes automatically

E0.4 OVERLOAD CURRENT

Error message deletes automatically

E0.5 REMOTE CONTROL

Lack of remote control power supply

Delete this error by switching the unit off and on again.

Loading...

Loading...