Page 9

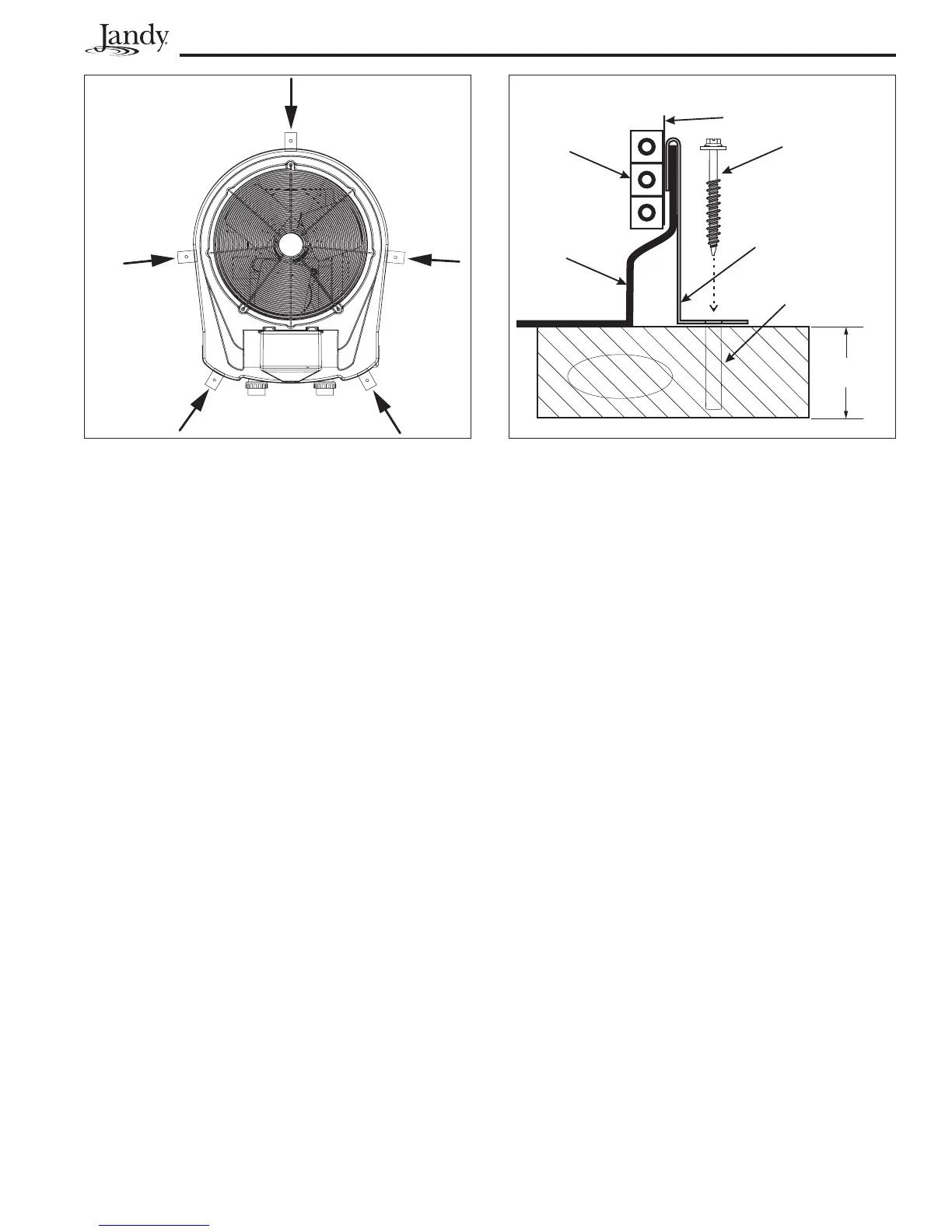

5. Mark the position of the hole in each clamp on the

equipment pad.

6. Drill a hole in the cement using a masonry drill

bit, with a diameter as determined by the concrete

anchor, at each of the marks on the equipment pad.

The hole should be approximately 1-1/2” deep.

7. Insert a bolt anchor into each of the holes. Be sure

the anchors are set completely into the holes.

8. Position the anchor clamps so that the holes in the

clamps are over the bolt anchors. Be sure that the

clamp hooks are over the lip of the heat pump base

(see Figure 3).

9. Insert an anchor bolt through each clamp into the

anchor and tighten to secure the clamp and heat

pump to the equipment pad.

Section 3. Water Connections

3.1 Plumbing Layout

Figure 4 illustrates the standard plumbing layout

with a single heat pump unit. Following the diagram

from right to left, the plumbing sequence is as follows:

Pool > Pool Pump > Filter > Heat Pump > Check

Valve > Chemical Loop > Chlorinator > Pool

NOTE For normal installations, do not install a shutoff

valve or any kind of variable restriction in the

water piping between the heat pump outlet and

the pool/spa.

Arrangement of pool system components other

than as illustrated in the preceding and following

diagrams can affect the operation of the heat pump’s

water pressure switch. Location of the heat pump above

or below the pool water surface can also affect operation

of the switch. In general, the pressure switch can be

adjusted to accommodate this effect if the heat pump

water connections are no more than five feet below the

pool water surface or no more than 11 feet above it. See

instructions for pressure switch adjustment (Section

5.6) in the heat pump start-up section of this manual for

more information. If the heat pump is installed outside

of this range, an external flow switch may need to be

installed in the plumbing upstream of the heat pump.

Call the Jandy Heat Pump Technical Service department

at (954) 970-4800 for details.

Be advised that when pool equipment is located

below the pool surface a leak can result in large scale

water loss or flooding. Jandy cannot be responsible for

such water loss or flooding or the damage caused by

either occurrence.

3.2 Water Connections at Heat Pump

Shipping plugs have been installed in the water

inlet and outlet ports of the heat pump at the factory.

Before installing any plumbing, remove the shipping

plugs. Filtered water is plumbed to the inlet, located on

the right side of the heat pump front panel. Heated water

flows through the outlet, located on the left side of the

heat pump front. Two inch unions are provided.

Plastic piping (PVC Schedule 40) should be

connected to the heat pump. The unions, provided with

the unit, accept 2” PVC pipe.

Figure 3. Anchor Clamp Installation

3" minimum

1/4" x 1-1/2"

STAINLESS STEEL

TAPCON

®

TYPE

CONCRETE SCREW

AND WASHER

(Installer Provided)

EVAPORATOR

COIL GUARD

EVAPORATOR

COIL

HEAT PUMP

PLASTIC BASE

HEAT PUMP

ANCHOR

BRACKET

3/16" DRILLED

HOLE

CONCRETE

EQUIPMENT PAD

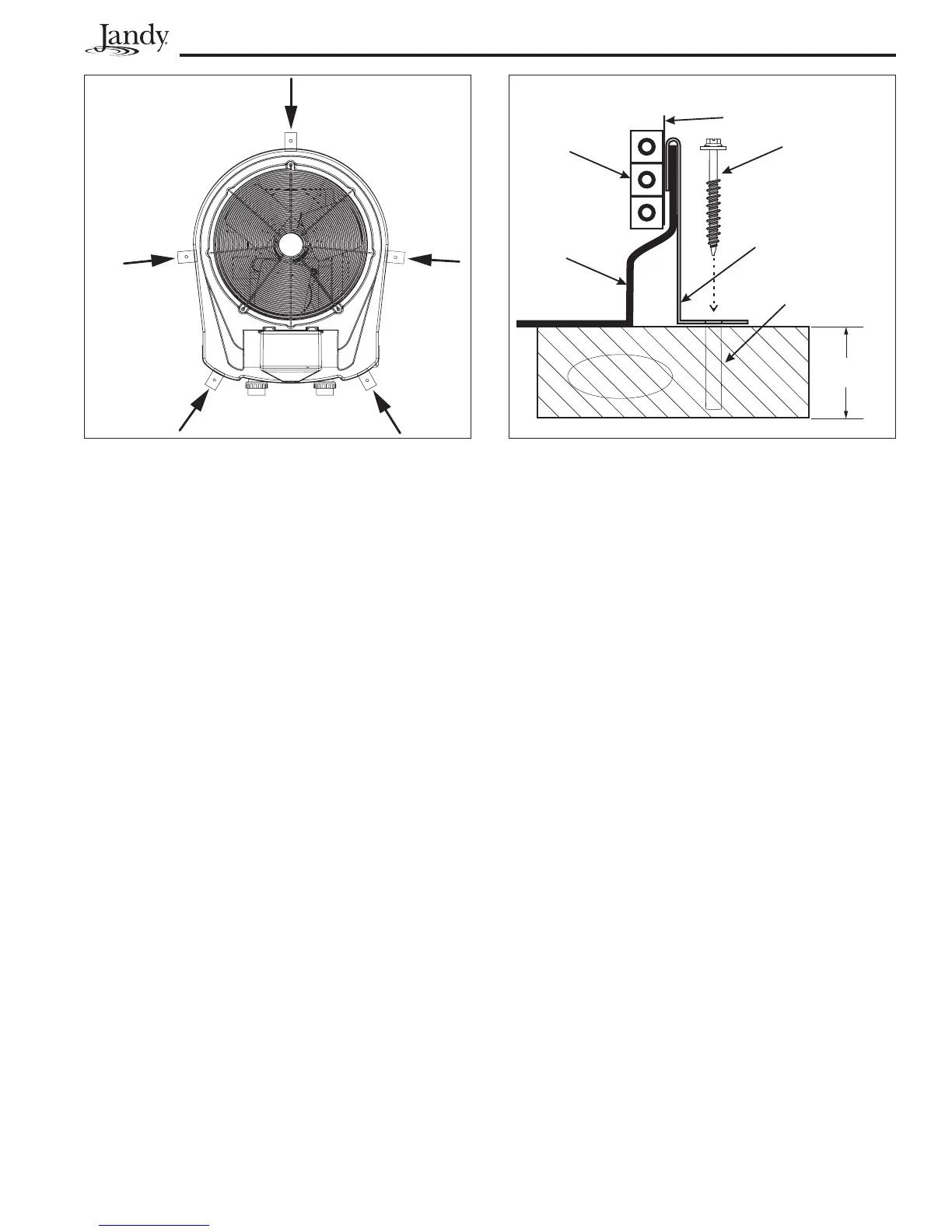

Attach anchor

brackets to base

of heat pump

where indicated

by the arrows.

Figure 2. Anchor Clamp Positions

Loading...

Loading...