Page 1 1

C artridge Pool Filters - C L and C V S eries Filters

9. After the pressure gauge has stabilized, turn the

bezel ring so that the arrow next to the word

CLEAN

to clog the pressure begins to increase. When the

needle of the pressure gauge aligns with the arrow

next to the word on the bezel, it is time

an increased pressure of between 10 and 12 psi

above original starting pressure.

Section 5. Filter Disassembly and

Assembly

W A RN I N G

N E V E R a t t e m p t t o a sse m b l e ,

d i sa sse m b l e o r a d j u st t h e f i l t e r w h e n

t h e r e i s p r e ssu r i ze d a i r i n t h e syst e m .

S t a r t i n g t h e p u m p w h i l e t h e r e i s

a n y p r e ssu r i ze d a i r i n t h e syst e m

ca n ca u se t h e f i l t e r l i d t o b e b l o w n

o f f , w h i ch ca n ca u se d e a t h , se r i o u s

p e r so n a l i n j u r y o r p r o p e r t y d a m a g e .

1. Turn off the pump. Switch off the circuit breaker

to the pump motor.

2. IMPORTANT: Completely open air release valve

on top of the lter tank to release all pressure

from inside the tank and system.

4. Remove the drain plug located at the bottom of the

5. Replace the drain plug.

6. Loosen the tank clamp ring retainer and remove

the clamp ring.

straight up until it clears the cartridges on the

inside of the tank.

8. Remove the manifold assembly by lifting it off of

the outlet tube and out of the tank.

the cartridge using the instructions in Section 6.3.

10. Using new cartridges or the clean original ones,

sure that they are correctly seated on the cartridge

support on the bottom of the tank.

11. Inspect the o-ring at the top of the outlet tube for

cracks and wear marks. Replace if necessary.

squarely over the cartridges and outlet tube.

13. Inspect the tank o-ring for cracks or wear marks.

Replace if necessary. Place the o-ring back onto

15. Replace the tank clamp ring. See Section 3.4 for

clamp installation.

16. Start the pump by following the procedures

outlined in steps 2 through 7 of Section 4.1.

Section 6. Maintenance

6.1 General Maintenance

water. Rinse off with a hose. Do not use solvents

to clean the lter, solvents will damage the plastic

components of the lter.

2. Check pressure during operation at least once a

week.

3. Remove any debris from the skimmer basket and

develop, turn off the pump and call a qualied

pool service technician.

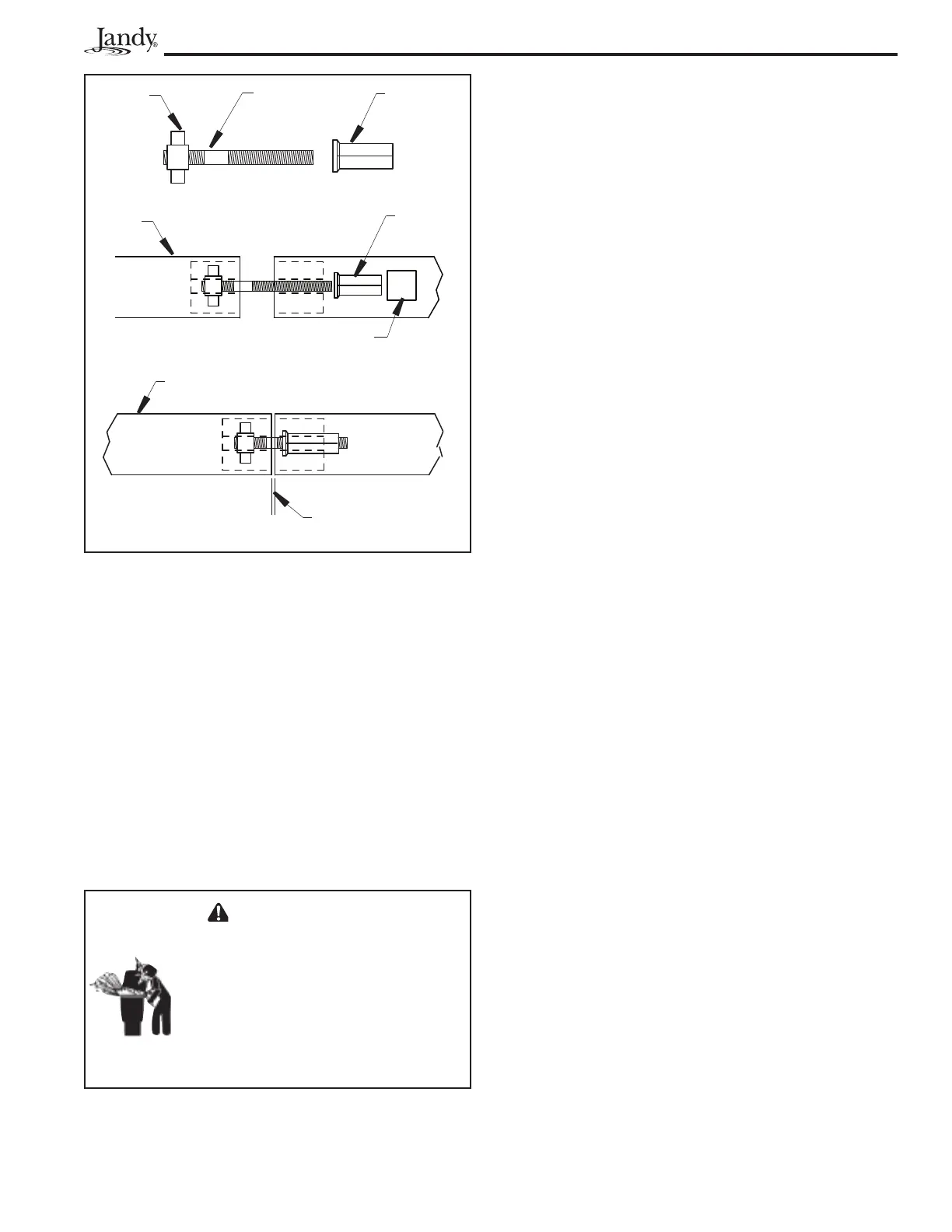

Figure 1 0 . Filter C lamp Ring A ssemb ly

" T " N u t

T h r e a d e d

R o d

T i g h t e n i n g

N u t w /

S h o u l d e r

Cl a m p

R i n g

T i g h t e n i n g

N u t w /

S h o u l d e r

Usea9/16"Socket

Cl a m p R i n g ,

Cl o se d P o si t i o n

GAPNOTTOEXCEED

1/16"

Loading...

Loading...