Preparing the Cab Frame Aperture

1 If damp or wet, dry the aperture area using a hot air gun

(sourced locally).

2 Use 'Active Wipe 205' to thoroughly clean and 'prime'

the trimmed sealant. Use a lint free cloth to apply the

'Active Wipe 205', allow 5 minutes flash off (drying)

time.

Note: Do not use any other type of cleaning fluids, otherwise

they may be absorbed into the old sealant and ultimately

prevent the new glass from bonding.

Preparing the New Glass

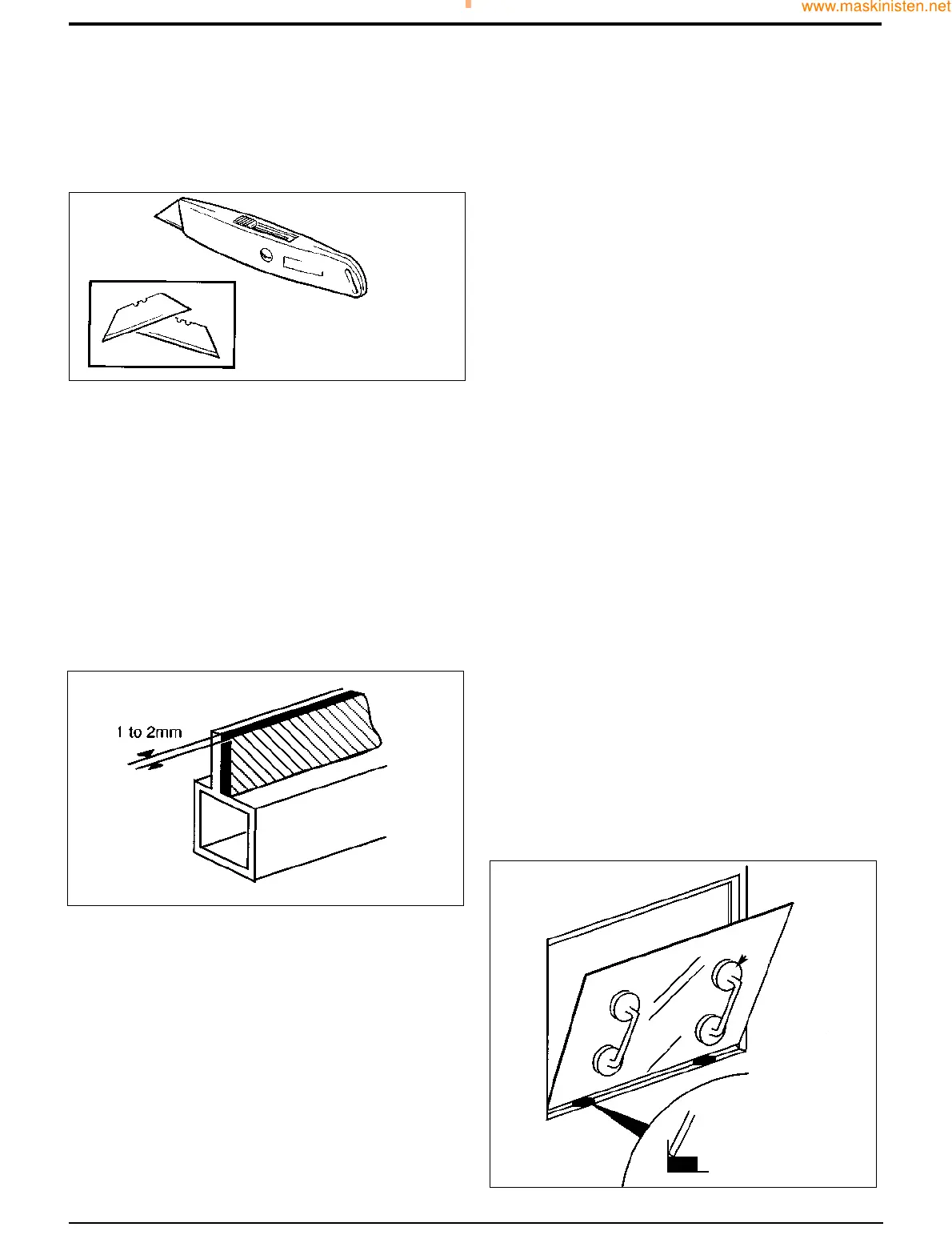

1 Make sure that the new glass correctly fits the frame

aperture K.

a Put two spacer blocks L onto the bottom part of the

frame aperture.

b Install the new glass on the spacer blocks - ALWAYS

USE GLASS LIFTERS M, refer to Service Tools.

Check that there is an equal sized gap all round the

edge of the glass.

Note: The spacer blocks are rectangular in section to give

two common gap widths. If necessary they can be trimmed

to a smaller size to give an equal sized gap around the glass.

IMPORTANT: The glass edges MUST NOT touch the frame,

otherwise movement of the frame will chip and eventually

break the newly installed glass.

21 - 3

Direct Glazing (cont'd)

Removing the Broken Glass and Old Sealant (cont'd)

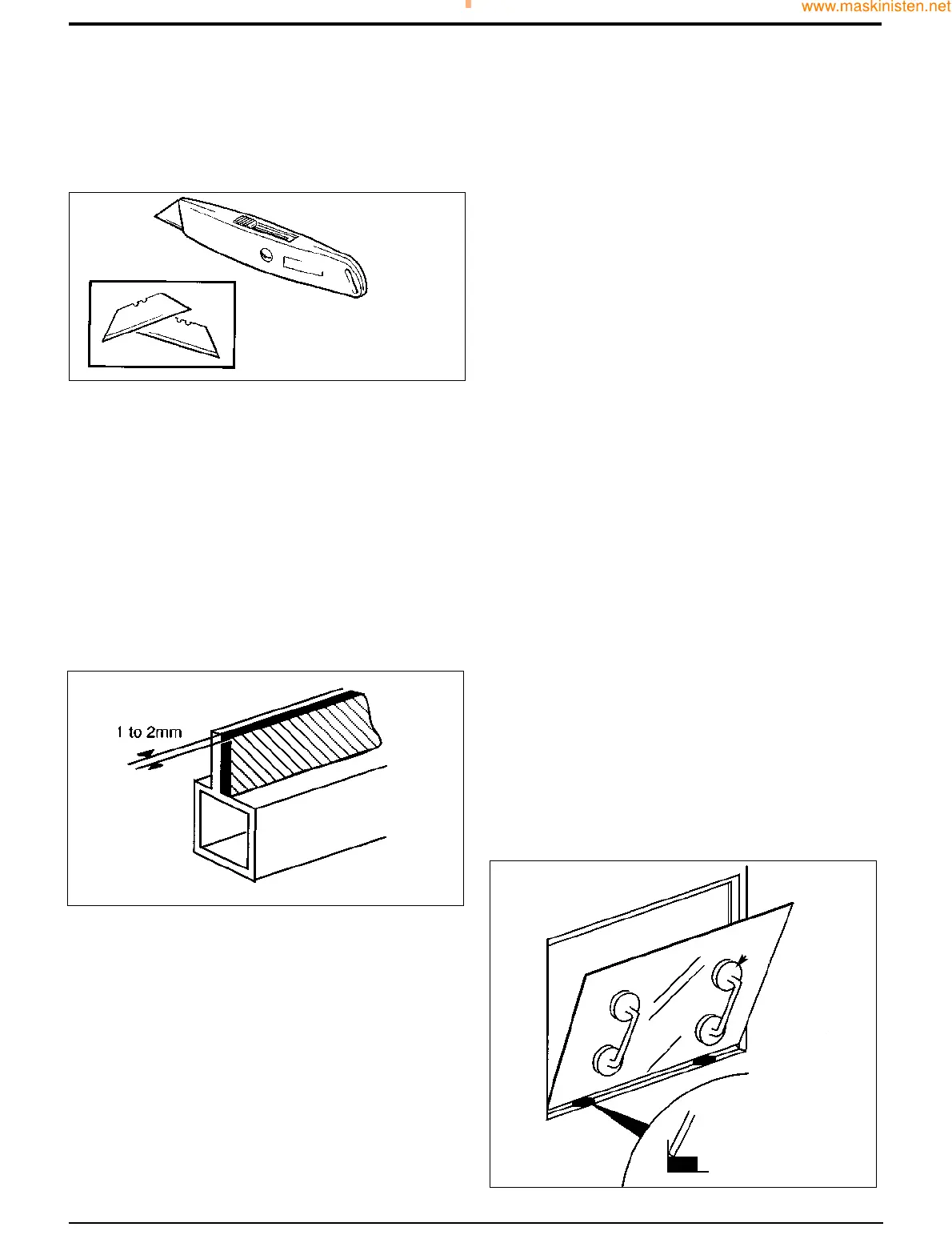

d Craft Knife H. The blades are replaceable.

(i) Insert the knife blade into the sealant.

(ii) Pull the knife along and cut out the old sealant.

Note: There are other tools available to cut out the old

sealant. For example, there is a long handle type craft knife

to give extended reach. Refer to Service Tools, for details of

this and any other tools.

4 Remove the cut off sealant and all remaining particles

of shattered glass.

5 If necessary, trim off the remaining old sealant to leave

approximately 1 to 2 mm on the upright face of the cab

frame aperture, as shown at J.

6 Apply a coat of 'Black Primer 206J' to the paintwork if:

a Paintwork was damaged or scratched during the

glass/sealant removal procedures.

b The old sealant was inadvertently cut back to the

cab frame during the glass/sealant removal

procedures.

Section B Body & Framework

9803/7130

Section B

21 - 3

Issue 1

Service Procedures

S186370

S189900

HH

JJ

S189910

MM

LL

KK

Loading...

Loading...