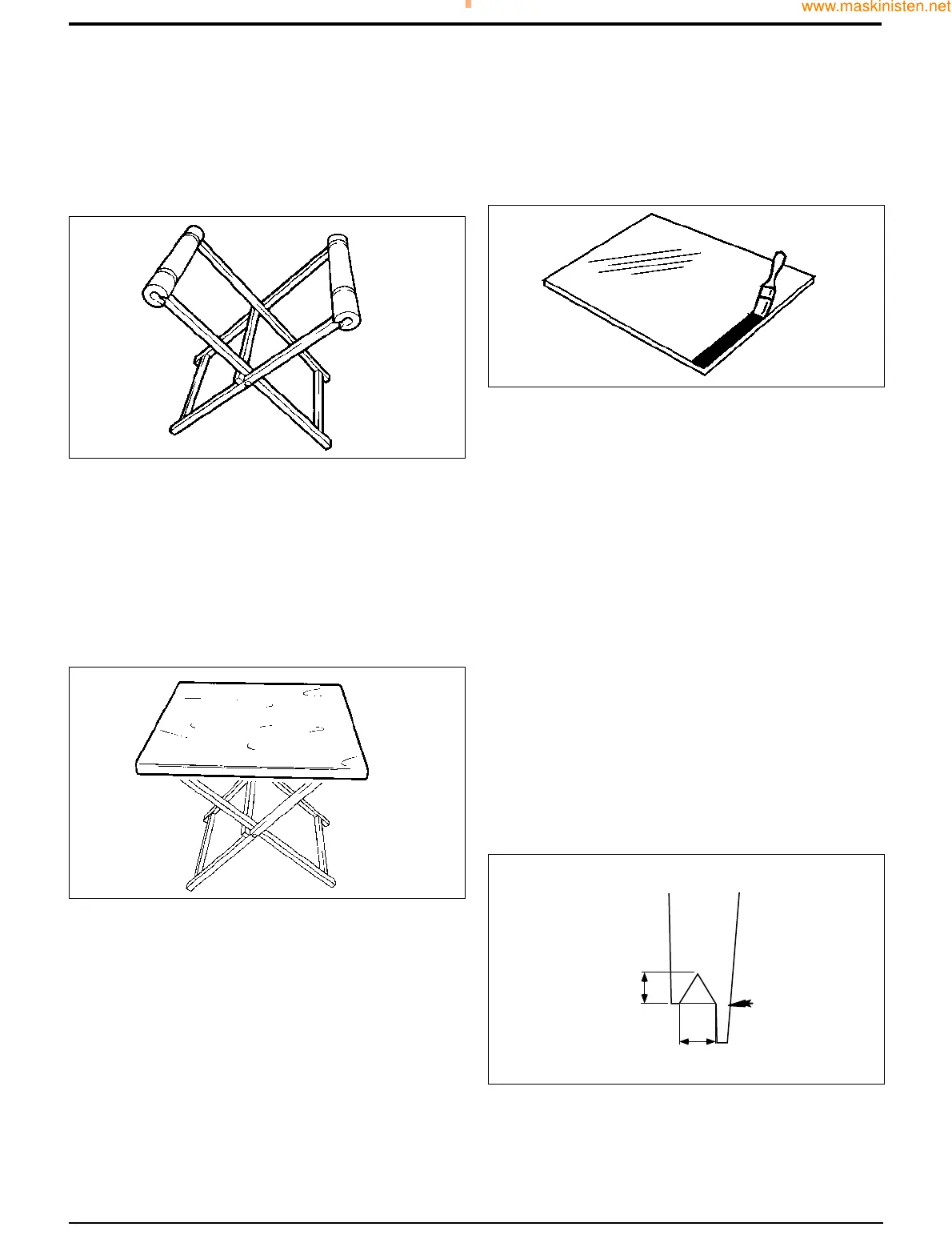

b If the glass does not have a black ceramic ink band,

paint a band on the glass using 'Black Primer 206J'.

The band should be approximately 25mm (1in) wide,

and the edge should be a neat straight line as shown

at R.

5 Install the Ultra Fast Adhesive cartridge,(refer to Sealing

and Retaining Compounds and Note 2 below) into a

suitable applicator gun:

a Remove the aluminium disc cover from the base of

the cartridge and discard the 'dessicant capsule'.

b Make sure that the rolled edge of the cartridge is not

damaged - if necessary, the edges should be

pressed flat, otherwise it will be difficult to remove

the cartridge from the applicator gun.

c Pierce the front 'nozzle' end of the cartridge to its

maximum diameter.

d Fit the pre-cut nozzle shown at S.

e Install the cartridge in the applicator gun.

Note 2: Cold material will be very difficult to extrude. The

cartridges must be pre-heated in a special oven, (refer to

Service Tools) for 1 hour to a temperature of 80°C (176°F).

Pre-heating the cartridges makes the adhesive more

workable and also brings the 'curing' time down to 30

minutes.

21 - 4

Direct Glazing (cont'd)

Preparing the New Glass (cont'd)

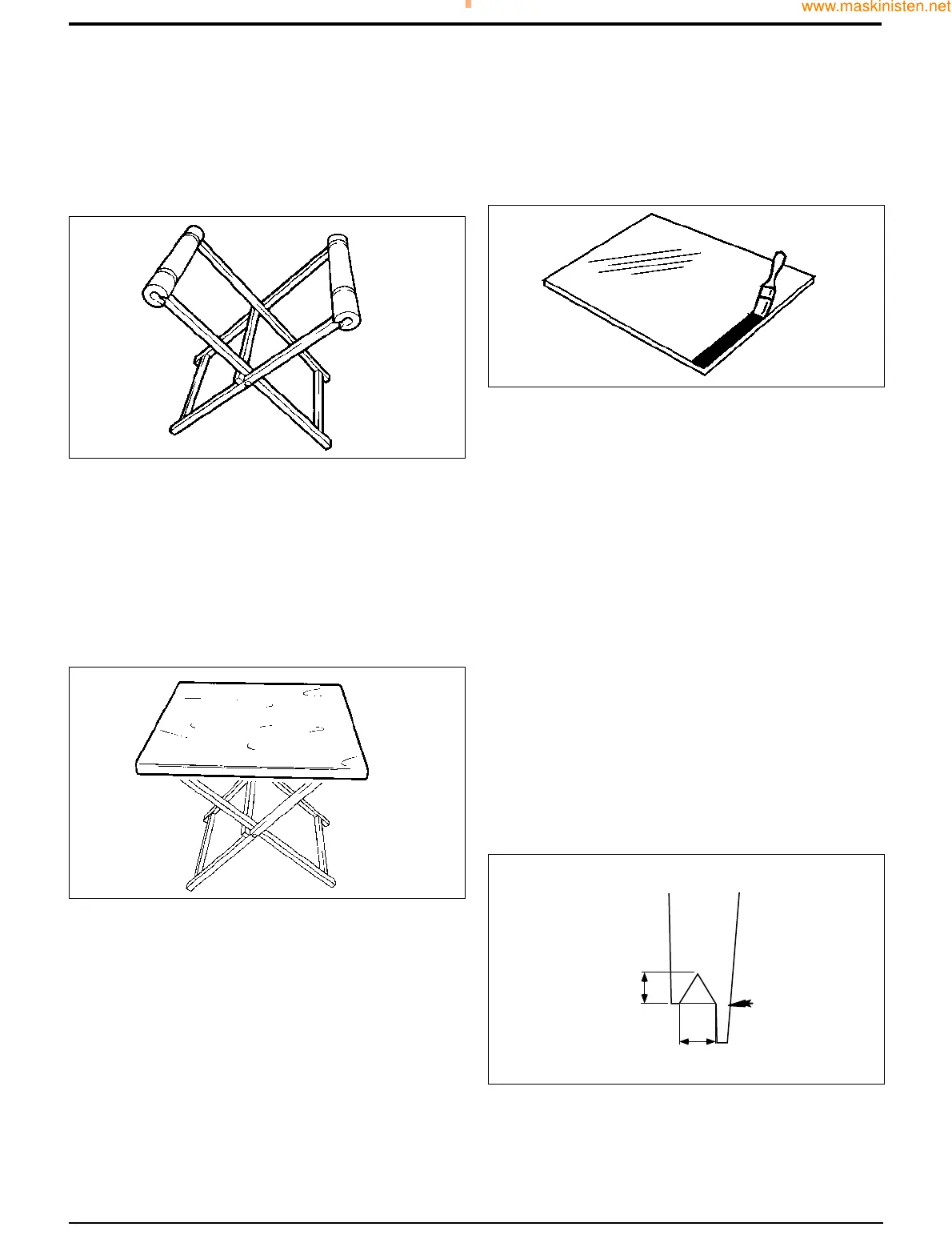

2 After checking for size, remove the new glass and place

it on a purpose made glass stand N, refer to Service

Tools.

Small panes of glass will need locating on a 600 x 700 mm x

15 to 19 mm thick plywood board P (sourced locally to fit

the glass stand N). It is recommended that an access hole is

cut in the board to accommodate the glass lifter, making it

easier and safer to handle small panes of glass. The board

should be covered with felt or carpet to give an anti-scratch

surface. Resting the glass on four spacer blocks will ensure

clearance of the cartridge nozzle tip during application of the

polyurethane sealant.

3 Make sure the glass is positioned on the stand the

correct way up (i.e. with the black ceramic ink band

upwards) ready for application of primer etc.

4aUse 'Active Wipe 205' to thoroughly clean and

'prime' the black ceramic ink band printed on the

glass (see Note 1). Use a lint free cloth to apply the

'Active Wipe 205', allow 5 minutes flash off (drying)

time.

Note 1: Do not touch the glass after cleaning with the

'Active Wipe 205'.

Section B Body & Framework

9803/7130

Section B

21 - 4

Issue 1

Service Procedures

S186280

S189920

NN

RR

Loading...

Loading...