S256120

CC

BB

S256110

41 - 7

Pinion Depth Setting

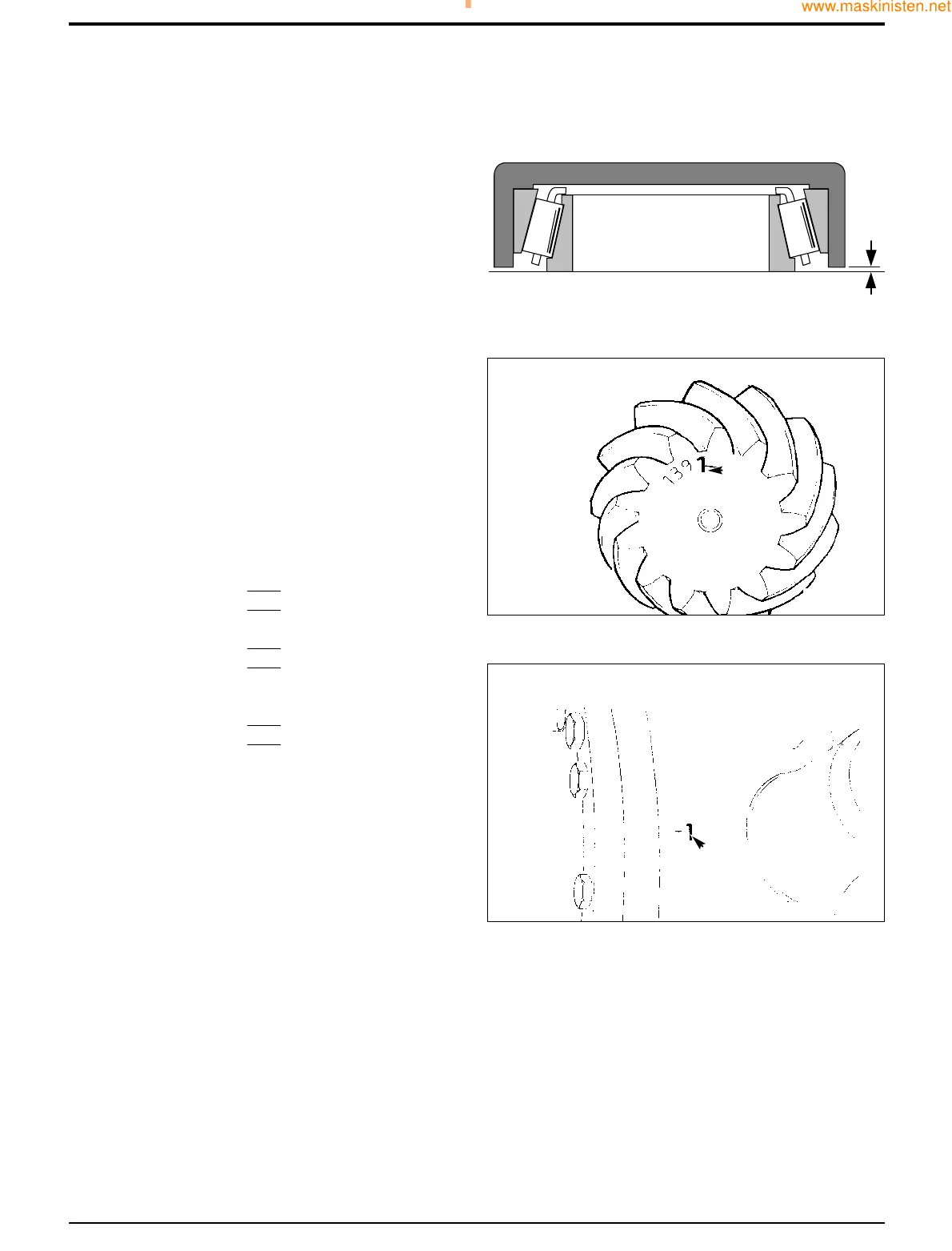

1 Place new pinion head bearing assembly on a flat

surface and position service tool 892/00174 over the

bearing. Measure gap A (e.g. 0.20 mm) and add this to

the cup depth stamped on the tool (e.g. 30.01 mm) to

obtain the bearing depth.

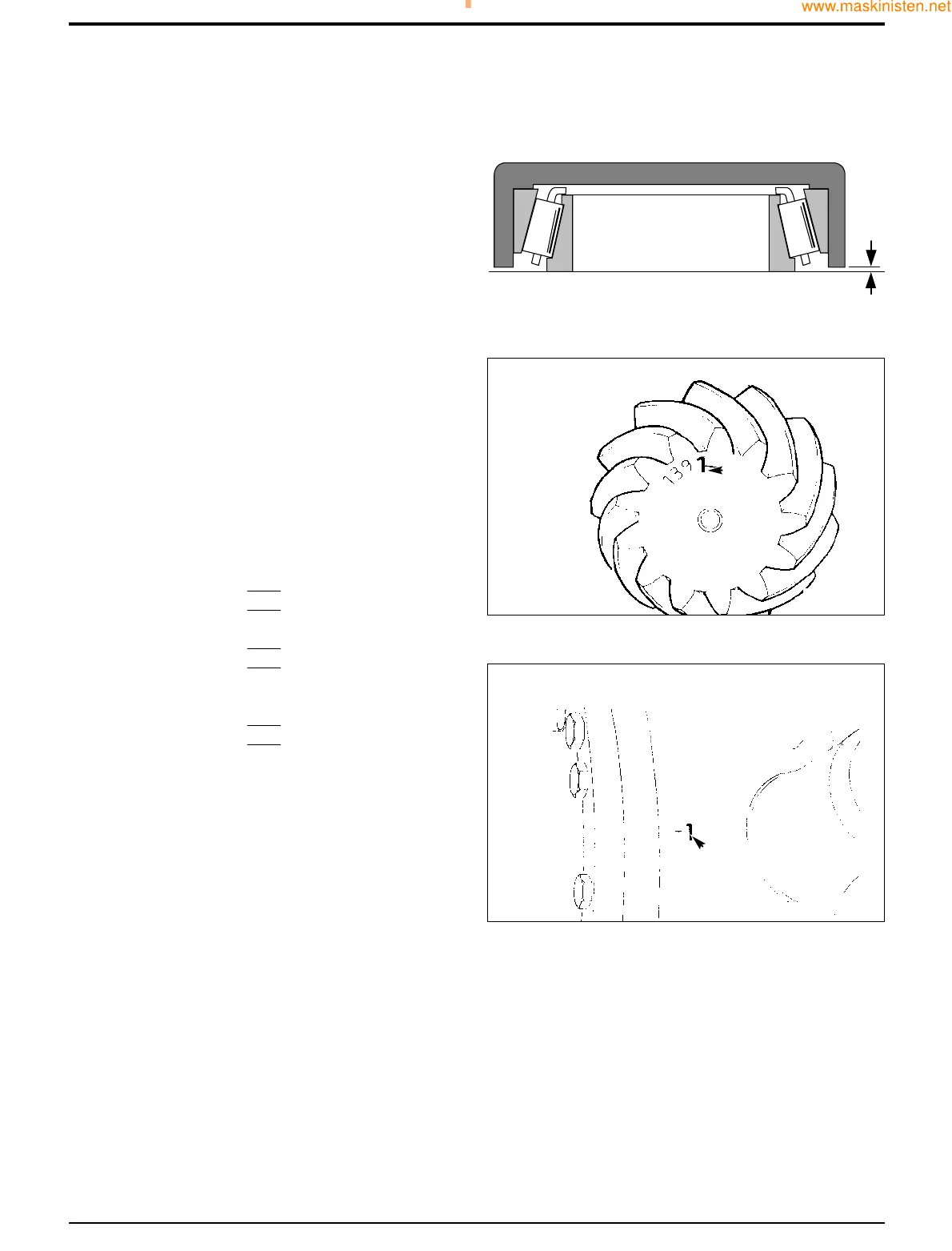

2 From the face of the pinion, obtain the etched deviation

figure B (e.g. + 2) which is in units of 0.01 mm. If

positive, add this to the bearing depth; if negative,

subtract from the bearing depth.

3 Obtain the deviation figure C (e.g. - 1) stamped on the

differential housing bolt flange. If negative, add to

bearing depth; if positive, subtract from bearing depth.

4 Subtract the total of the above figures from the

standard value of 31.19 mm. The result will be the

thickness of shims required behind the pinion head

bearing cup.

Example (all dimensions in millimetres)

Cup depth 30.01

Gap A +0.20

Bearing depth 30.21

Pinion deviation B (+ 2) +0.02

Housing deviation C (- 1) +0.01

Total 30.24

Standard value 31.19

Less Total above 30.24

Shim Thickness 0.95

Note: In the event that the setting data stamp has been

ommited from the drivehead casing, adopt the following

setting procedure:

Revise the shim pack size by the difference in setting height

marked on the old and new crownwheel pinion sets.

Section F Transmission

9803/7130

Section F

41 - 7

Issue 1

Front Axle

A184400

AA

Loading...

Loading...