6 - 4

Replacement (continued)

4. a. Install the covers over the motor.

b. Check the amount of oil in the gearbox.

c. Bleed air from the motor (see Motor Bleeding).

d. If the traction motor has been dismantled and

serviced, carry out the functional tests detailed

under Testing later in this section.

e. Install the drive sprocket (see Drive Sprocket,

Replacement, Section J).

f. Remove the wooden blocks.

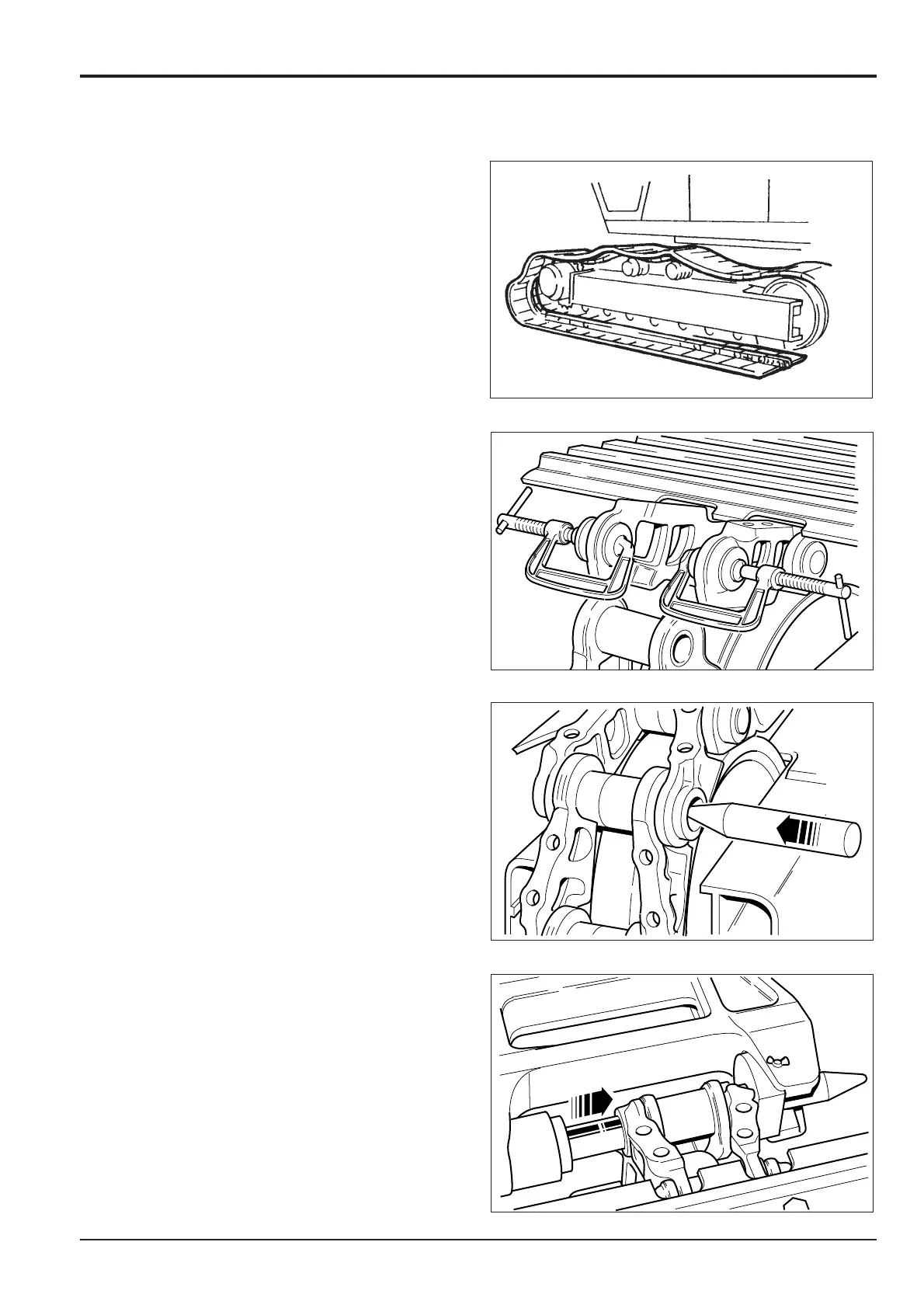

g. Position the lower frame on the track.

h. Move the track link by reversing step 1 of Removal.

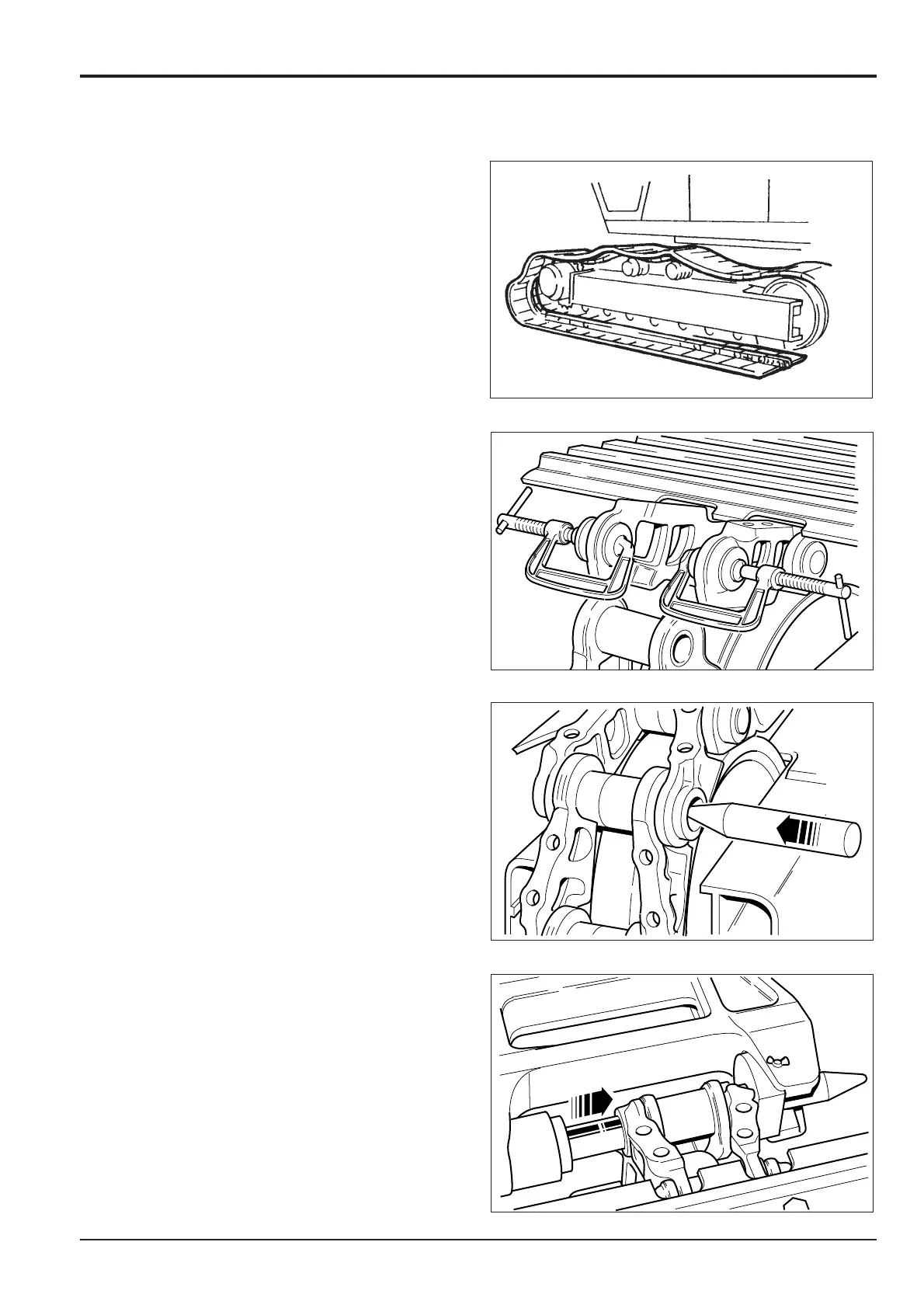

i. Clean the seal ring housings in the chain link. Insert

the seal rings and clamp into position.

j. Using a plastic hammer, tap the upper link down to

align holes.

Note: As the links overlap, the seal rings will be held in

position. Remove ‘G’ clamps.

k. Insert the pointed guide pin from the inner face and

tap through its full length.

l. Position a suitable hydraulic press so that its ram

aligns with the guide pin.

m. Insert the master pin into its locating hole.

n. Slowly operate the hydraulic ram and press the

master pin into position.

o. Re-locate the track shoes and tighten the bolts (see

Checking Shoe Plate, Routine Maintenance,

Section 3).

Section F

Transmission

9803/6400

Section F

6 - 4

Issue 2*

Motor/Gearbox

Loading...

Loading...