7 - 1

Dismantling

Note: The numbers in the following section refer to the

illustrations on pages F/7-15 and F/7-16.

Before starting the dismantling, drain the oil, clean all the

surfaces with a suitable solvent and dry with compressed air.

Discard all 'O'-rings and seals which are disturbed during

dismantling.

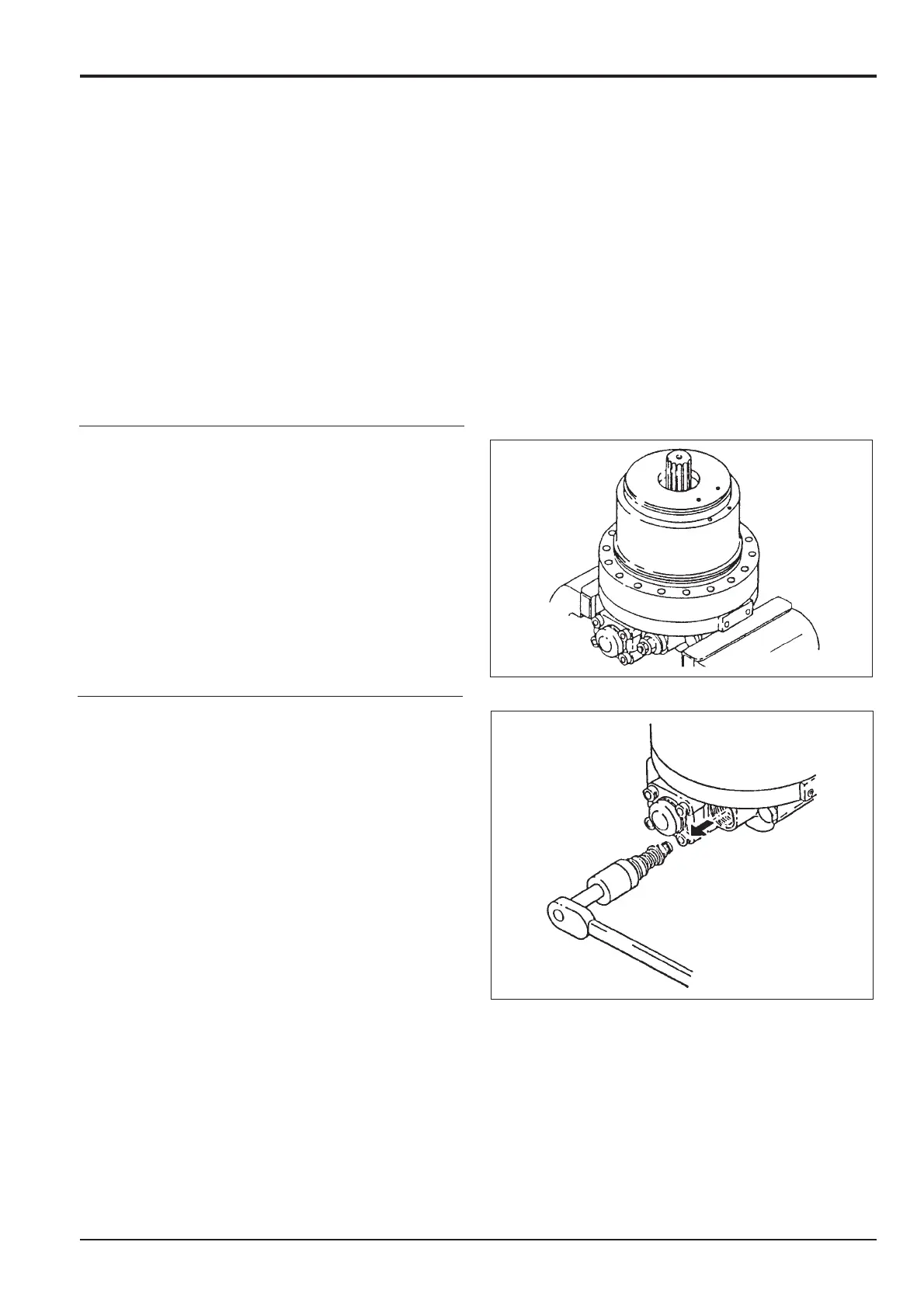

1. With the motor/gearbox assembly removed from the

machine as described in the previous section.

Unscrew the three socket head screw and separate the

hydraulic motor from the gearbox.

2. Remove the O ring from its groove in the motor.

3. Fix the motor into a suitable vice or jig with the shaft

facing upwards.

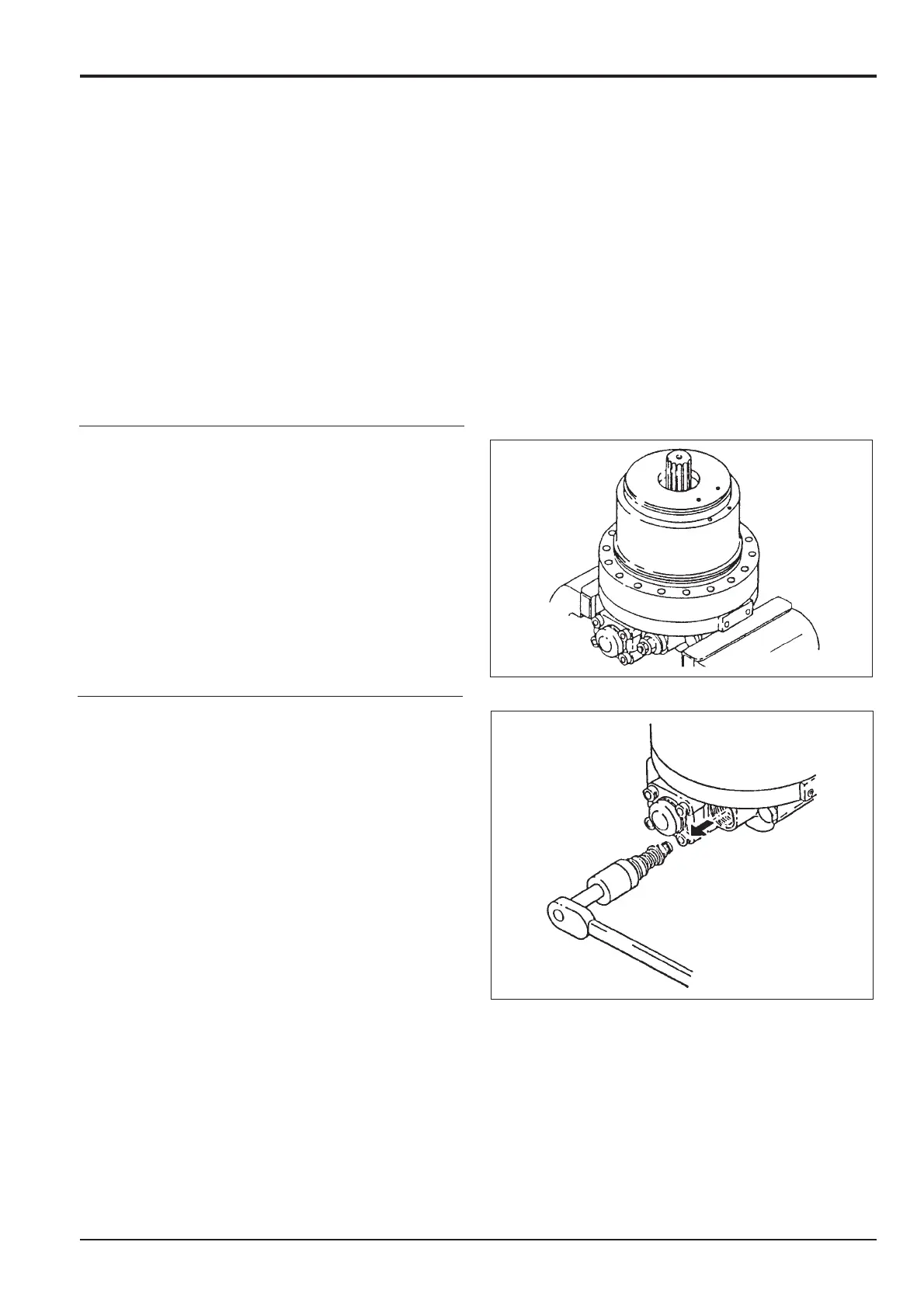

4. Base plate disassembly

a. Relief valve disassembly.

Loosen the plug (2-7-6) and remove the relief valve

sub-assembly (2-7).

b. The (2-7-6) plug and (2-7-1) relief housing are

press fitted but the (2-6-2) poppet is not.

Remove the (2-7-3) poppet seat from the (2-1)

housing using the poppet seat removal jig.

Note: When removing the (2-7) relief valve sub-assembly, the

relief set pressure will be lost if the (2-7-16) nut and (2-7-15)

set screw are loosened, so take care not to loosen them. Do

not disassemble the relief valve unless absolutely necessary.

Section F

Transmission

9803/6400

Section F

7 - 1

Issue 2*

Motor

*

*

*

Loading...

Loading...