Part No. 960-000187R_Rev. A © 2016 JCM American Corporation

DBV-500 Banknote Validator JCM® Training Overview November, 2016

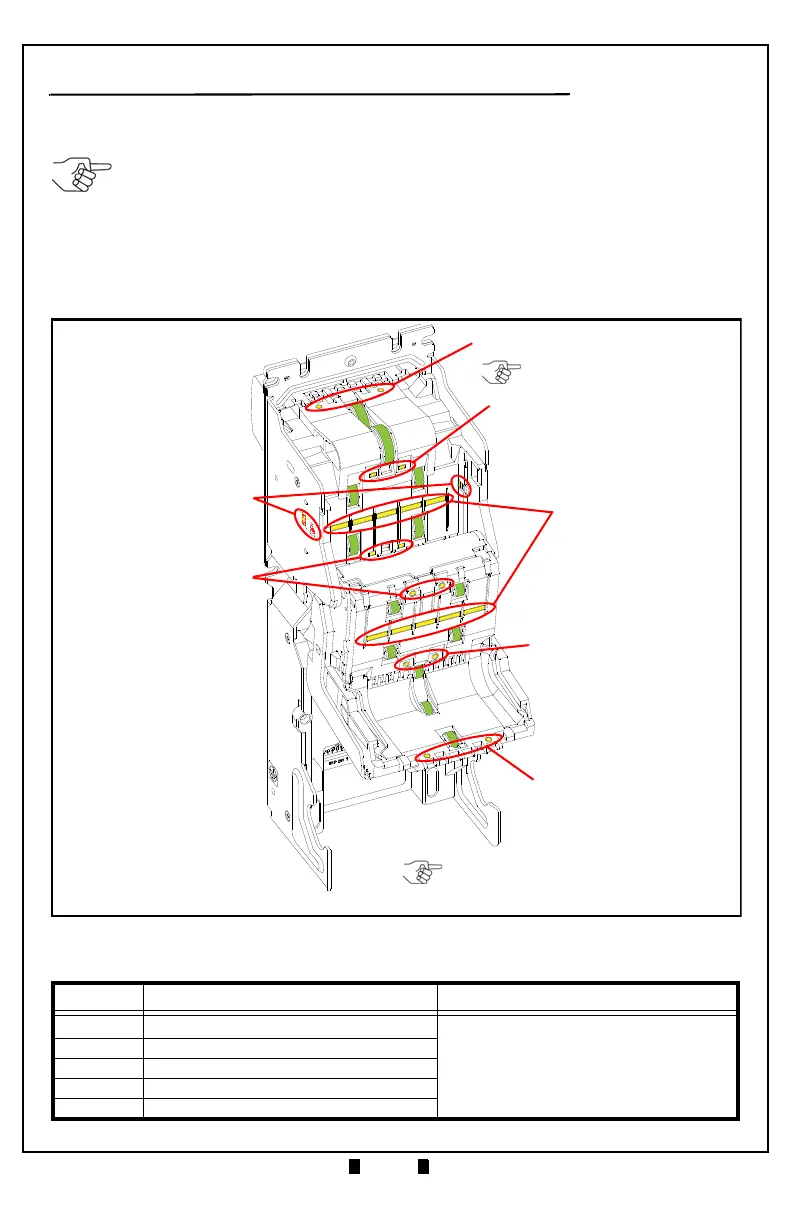

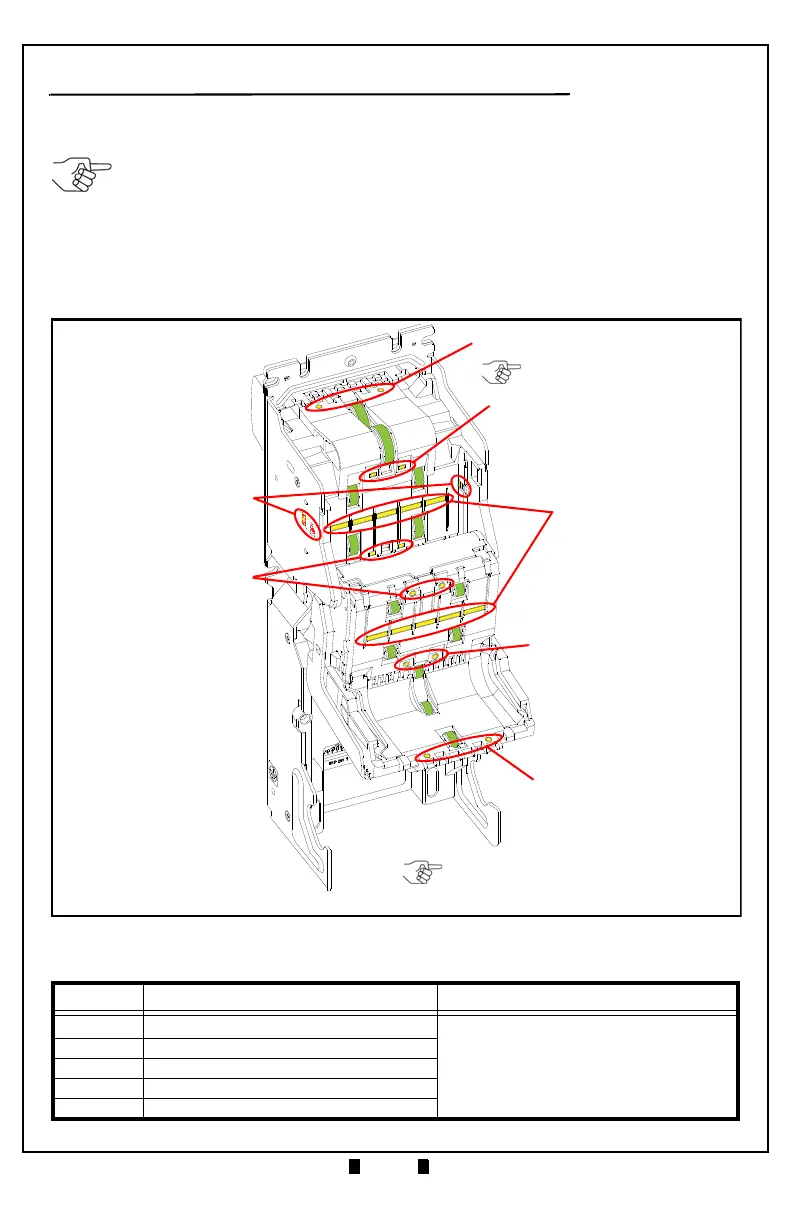

SENSOR AND ROLLER CLEANING PROCEDURE

To clean the DBV-500 Unit, gently wipe the Sensors and Rollers using a clean

(slightly damp) lint-free Microfiber cloth.

1. Turn the DBV-500 Unit Power OFF.

2. Open the Validation Guide.

3. Clean the Lens of each Sensor (yellow) and the Rollers (green). (See Figure 3

for Locations and Table 5 for Cleaning Methods.)

4. Calibrate the DBV-500 Unit after cleaning.

Table 5 DBV-500 Sensor and Roller Cleaning Methods

Label Sensor Description Cleaning Method

a

Entrance Sensor

b Centering Start Sensor

c Side Sensor

d COB Sensor

e Exit Sensor

NOTE: DO NOT use Alcohol, solvents, citrus-based products or scouring agents.

These items may cause damage to the Validation Section Sensors and Rollers.

e

g

a

a

b

e

d

a

b

e

c

b

a

NOTE: Clean the surface of each Roller

(green) using a clean (slightly damp)

lint-free Microfiber cloth.

NOTE: Always calibrate the

DBV-500 Unit after cleaning!

Figure 3 DBV-500 Sensor and Roller Locations

Wipe Sensors (yellow areas) clean using a

clean (slightly damp) lint-free Micro-fiber cloth.

Wipe Rollers (green areas) clean using a

clean (slightly damp) lint-free Microfiber cloth.

Loading...

Loading...