SynMag 2600/3100/3600/4100/5100 8 Welding programmes

BA-0006 • 2020-02-08 EN - 17

SynMag 3600/4100/5100

Use the knob in Fig. 13 pos. J on page EN-15 to set the spot welding time. The process sequence

is as follows:

• Step 1: Press and hold the torch trigger. The shielding gas flows. The arc ignites.

• Step 2: The arc automatically goes out after the set time has elapsed. The shielding gas continues

to flow for a brief period.

MIG/MAG 4-step welding

SynMag 2600/3100/3600/4100/5100

The process sequence is as follows:

• Step 1: Press and hold the torch trigger. The shielding gas flows and the arc ignites.

• Step 2: Release the torch trigger. Weld with the set energy value.

• Step 3: Press and hold the torch trigger. The arc goes out.

• Step 4: Release the torch trigger. The gas post flow time elapses. The welding process is finished.

MIG/MAG 2-step welding

SynMag 2600/3100/3600/4100/5100

The process sequence is as follows:

• Step 1: Press and hold the torch trigger. The shielding gas flows. The arc ignites.

• Step 2: Release the torch trigger. The arc goes out. The shielding gas continues to flow. The welding

process is finished.

8 Welding programmes

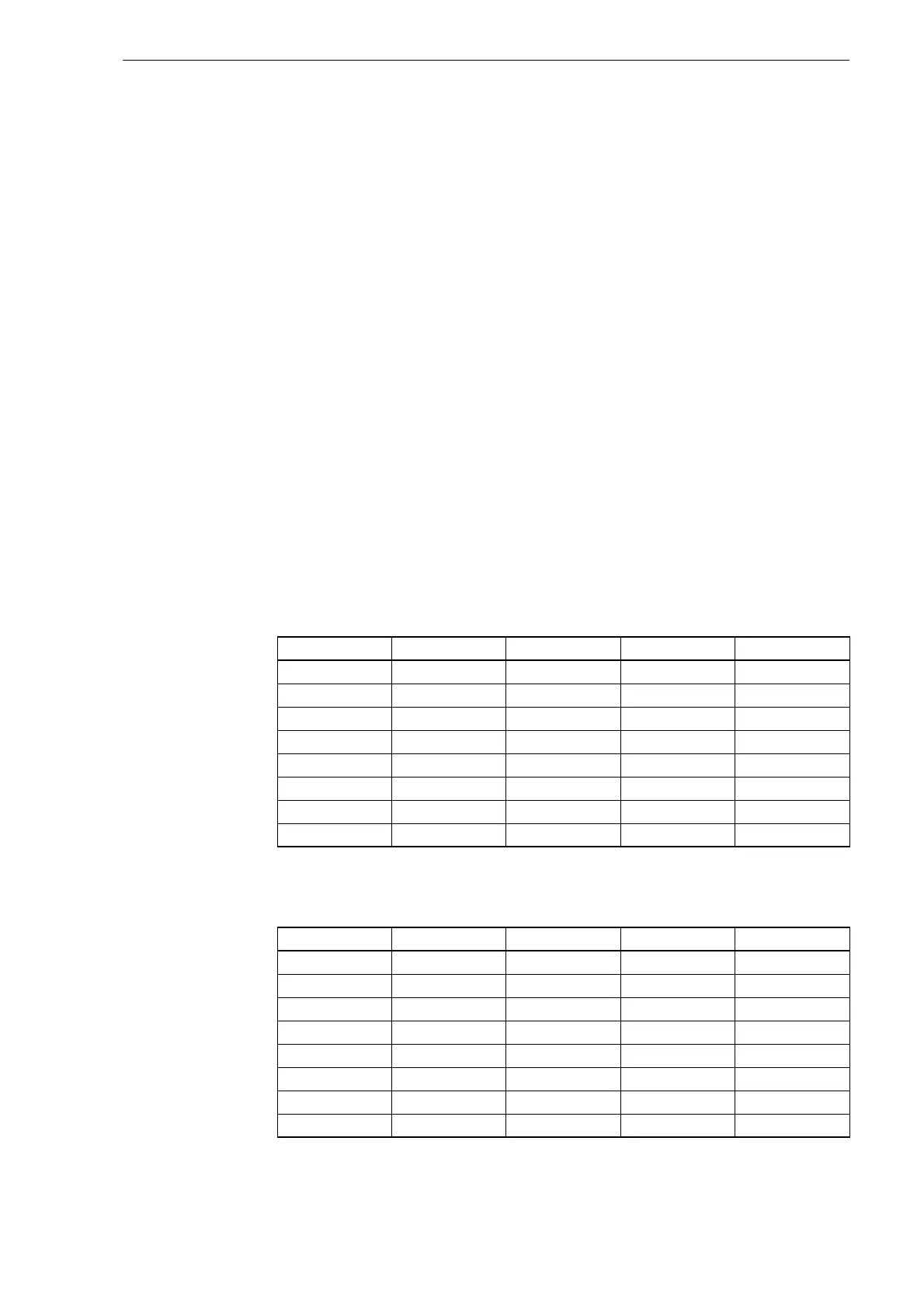

8.1 SynMag 2600

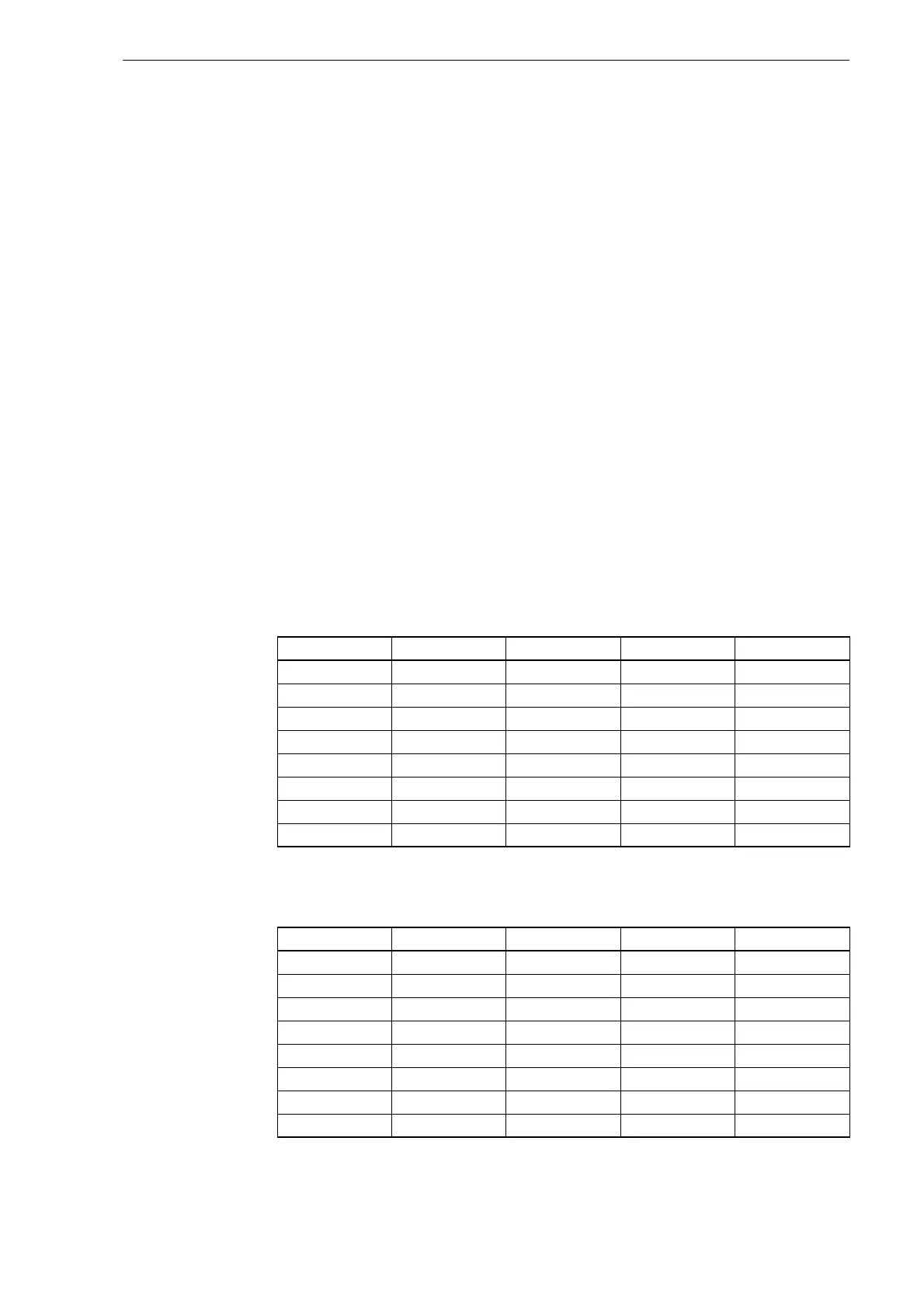

8.2 SynMag 3100

Tab. 5 SynMag 2600 welding programmes

Programme Rec. level Material Wire Ø Shielding gas

1 1–12 St 0.8 82 Ar / 18 CO²

2 1–12 St 1.0 82 Ar / 18 CO²

3 1–11 VA 0.8 97.5 Ar / 2.5 CO²

4 1–12 VA 1.0 97.5 Ar / 2.5 CO²

5 1–11 Alu 1.0 Argon

6 1–12 Alu 1.2 Argon

7 1–12 CuSi 0.8 Argon

8 1–12 CuSi 1.0 Argon

Tab. 6 SynMag 3100 welding programmes

Programme Rec. level Material Wire Ø Shielding gas

1 1–12 St 0.8 82 Ar / 18 CO²

2 1–12 St 1.0 82 Ar / 18 CO²

3 1–12 St 1.2 82 Ar / 18 CO²

4 1–10 VA 0.8 97.5 Ar / 2.5 CO²

5 1–12 VA 1.0 97.5 Ar / 2.5 CO²

6 1–12 VA 1.2 97.5 Ar / 2.5 CO²

7 1–10 Alu 1.0 Argon

8 1–12 Alu 1.2 Argon

Loading...

Loading...