8

Operation Manual

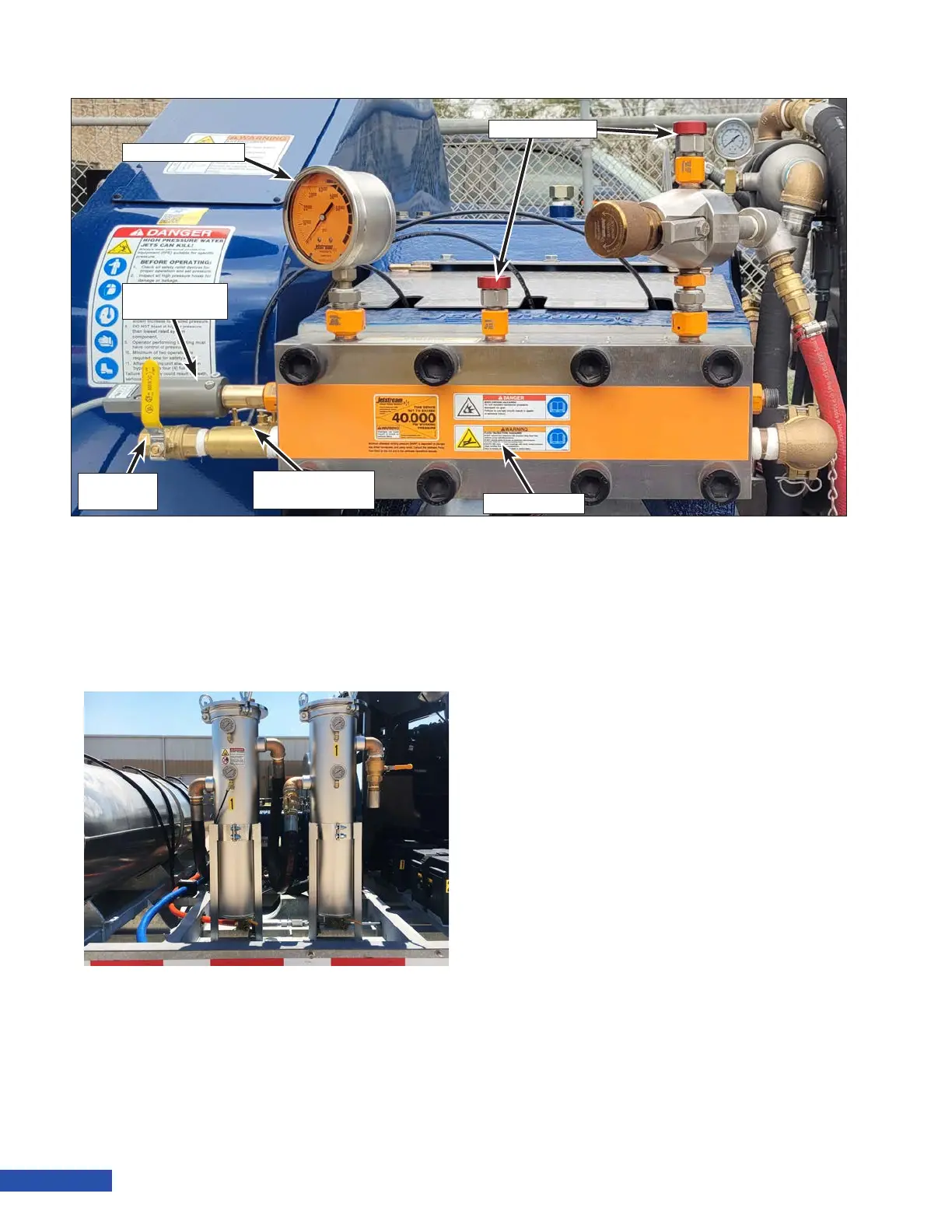

charge pump into the rst lter and then the

second lter in line. A ball valve is tted to the

inlet side of the lter after the charge pump.

This is used when the associated pump will

not be used, but there is water supply due to

use of the opposite triplex pump.

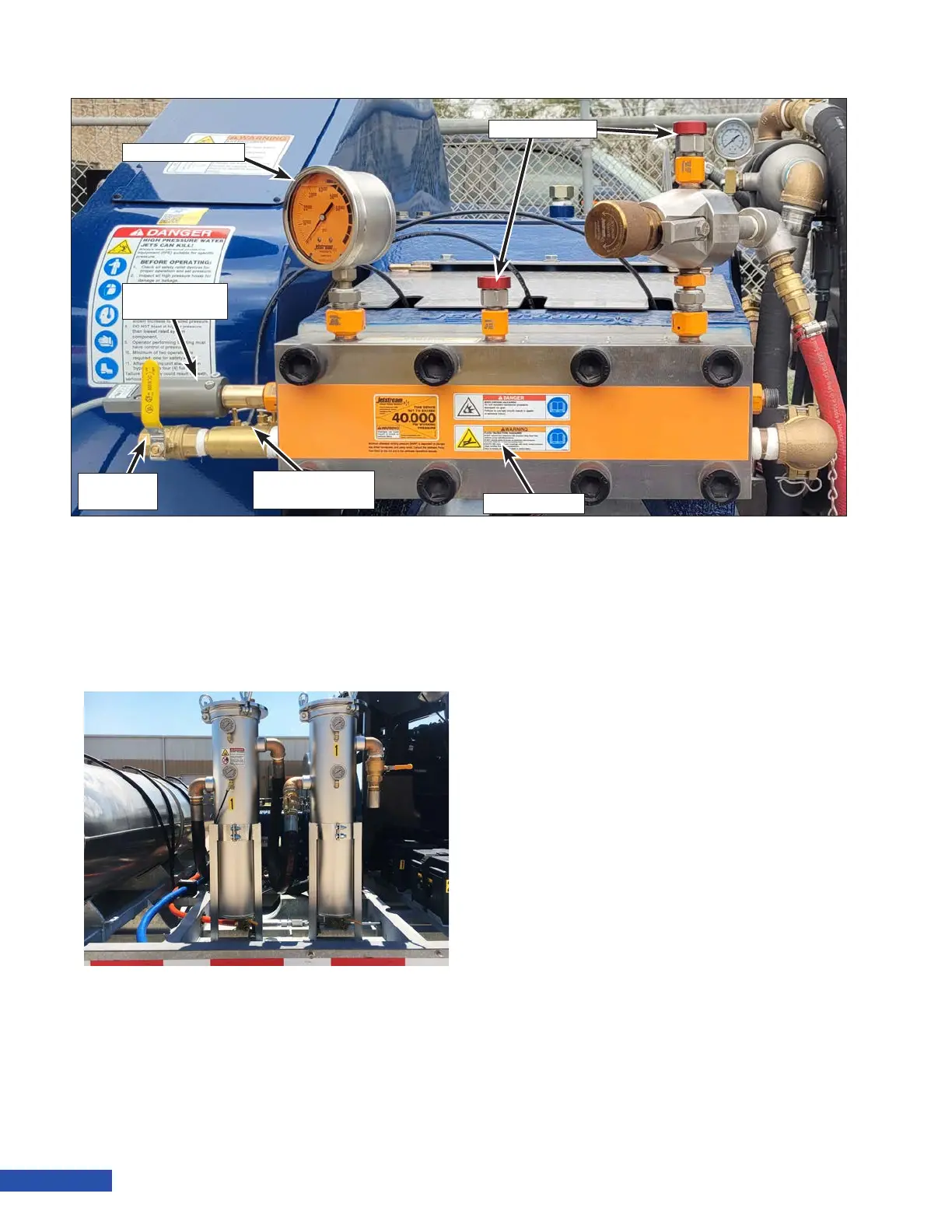

Manifold

The manifold houses many of the components

that make up the uid end of the pump in-

cluding the uni-valves. The three uni-valves

each consist of a suction and discharge valve

combined into one assembly. The valves con-

vert low pressure water to high pressure water.

.

Manifold Drain Valve

The manifold drain valve allows the manifold

to be ushed of contaminants prior to pump

usage. It is also used to purge air during op-

eration start up.

Water Lubrication System

The water lubrication system provides water

to the packing in the pump. The water lubri-

cates and cools for optimum operation of the

pump. The system includes a manifold and

three water lines. Needle valves are present

on manifolds that are pressure fed (all 40K

units). The needle valves control the amount of

ow to each stufng box and must be prop-

erly adjusted during operation. Manifolds that

are not pressure fed have a xed ow. Refer to

“Charge Pump (40K Units)” on page 13 for

more information on pressure fed manifolds.

Pressure Gauge

The liquid lled pressure gauge allows the

operator controlling the pump to monitor the

pressure of the system.

Pressure Gauge

Hydro-Throttle

Switch

Water Lubrication

System

Manifold

Drain Valve

Manifold

Rupture Discs

Figure 9: Pump Components

Figure 10: Water Filter Housings

Loading...

Loading...