36

Operation Manual

3. Belt Inspection - Inspect the belts for

cracks, damage, glazing or any other

defect. Replace as necessary. Replace the

belts as a set and adjust the new belts as

outlined in “Adjusting Belt Tension” on

page 75.

4. Regular Stufng Box Lubrication Check

- Remove stufng boxes, clean power-

frame bore, lubricate with anti-seize

or petroleum jelly, and replace stufng

boxes.

Winterizing The Unit

Severe damage can result if the waterblast

unit is not protected from freezing condi-

tions. The stufng boxes hold water that can

freeze causing damage to the stufng boxes,

uni-valves, plungers and manifold. To prevent

freezing drain the water from all hoses, charge

pump and tanks, and add anti-freeze to the

stufng boxes.

If the unit is to be idle for any period of time

that would allow freezing in the pump or pip-

ing, utilize the following procedure:

1. Drain the water from the tank.

2. Disconnect the water supply suction line

and high pressure discharge hose from the

manifold.

3. Drain the manifold of water and close the

drain.

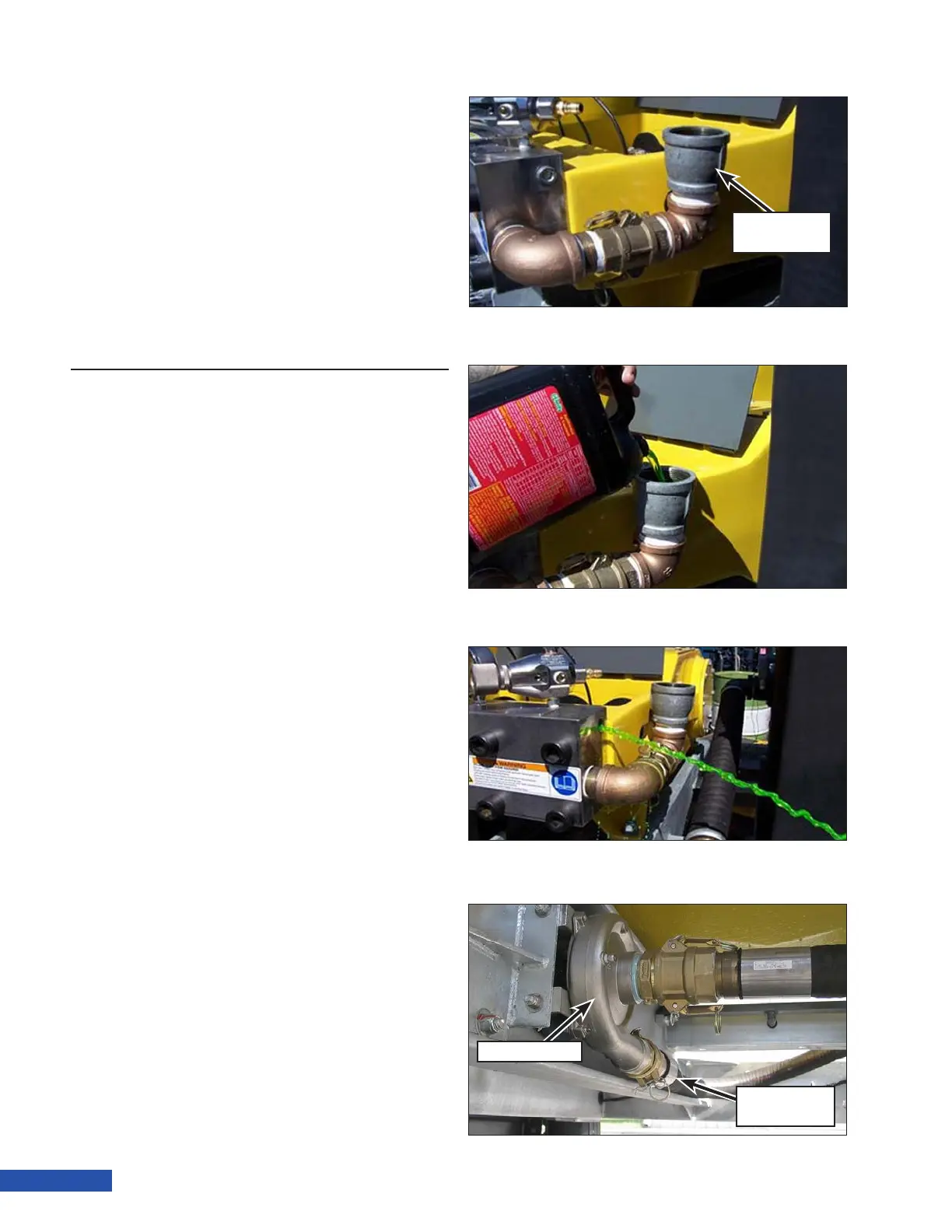

4. Assemble pipe ttings into a funnel as-

sembly as shown in (Figure 44).

5. Install the assembly on the suction side

of the manifold.

6. Pour a glycol based anti-freeze solution

into the funnel as shown in (Figure 45).

Approximately 0.5 gal. (2 L) of anti-freeze

is required.

7. Place the override switch in the ON posi-

tion to bypass the low water shutdown.

8. Before starting the engine, check the area

in the path of the discharge tting on the

manifold. Ensure the area is clear. Anti-

freeze will be discharged from the dis-

charge tting during this procedure.

Funnel

Assembly

Figure 44: Funnel Assembly Installation.

Figure 45: Adding Anti-Frieeze.

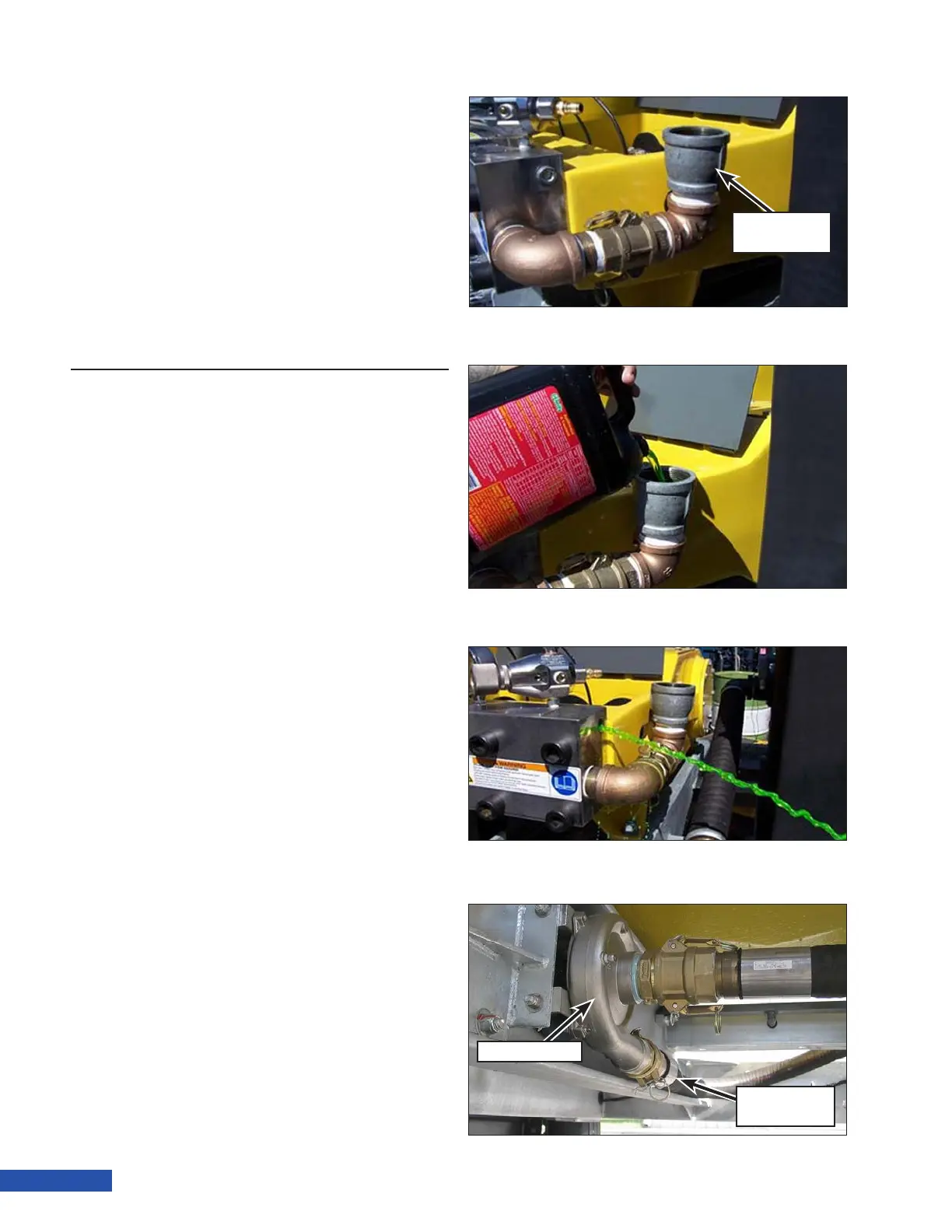

Figure 46: Draining the Anti-Freeze.

Discharge

Hose

Charge Pump

Figure 47: Draining the Charge Pump.

Loading...

Loading...