74

Operation Manual

Changing PTO Oil

1. Place a container below the PTO large

enough to capture the oil in the PTO case

(26 oz) (0.77 L).

2. Remove the drain plug (Figure 135) and

allow the oil to fully drain from the case.

3. When the oil has drained, install the drain

plug.

4. Remove the breather and ll with 10W40

synthetic oil until it begins to show in

the site gauge. Continue adding oil slowly

once visible in the site gauge so as not

to overll. The oil is slow to drain into the

reservoir.

5. Install the ll plug.

Checking Belt Tension

1. Disengage the clutch and stop the engine.

2. Open the access cover on the belt guard.

3. Locate the decal on the cover to nd the

correct belt tension specication.

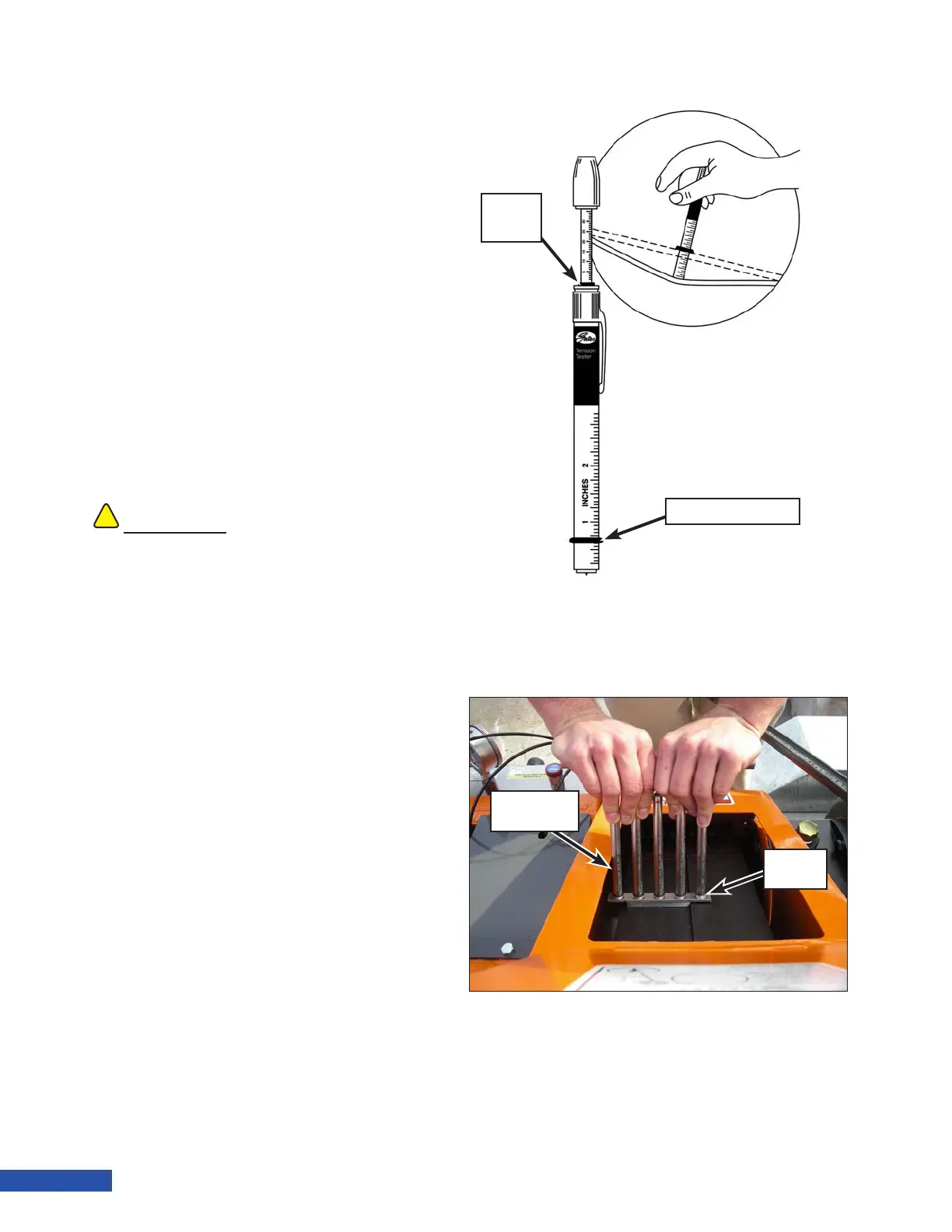

4. Adjust the deection O-ring (Figure

137) on a belt tension tool for the proper

deection as specied on the decal.

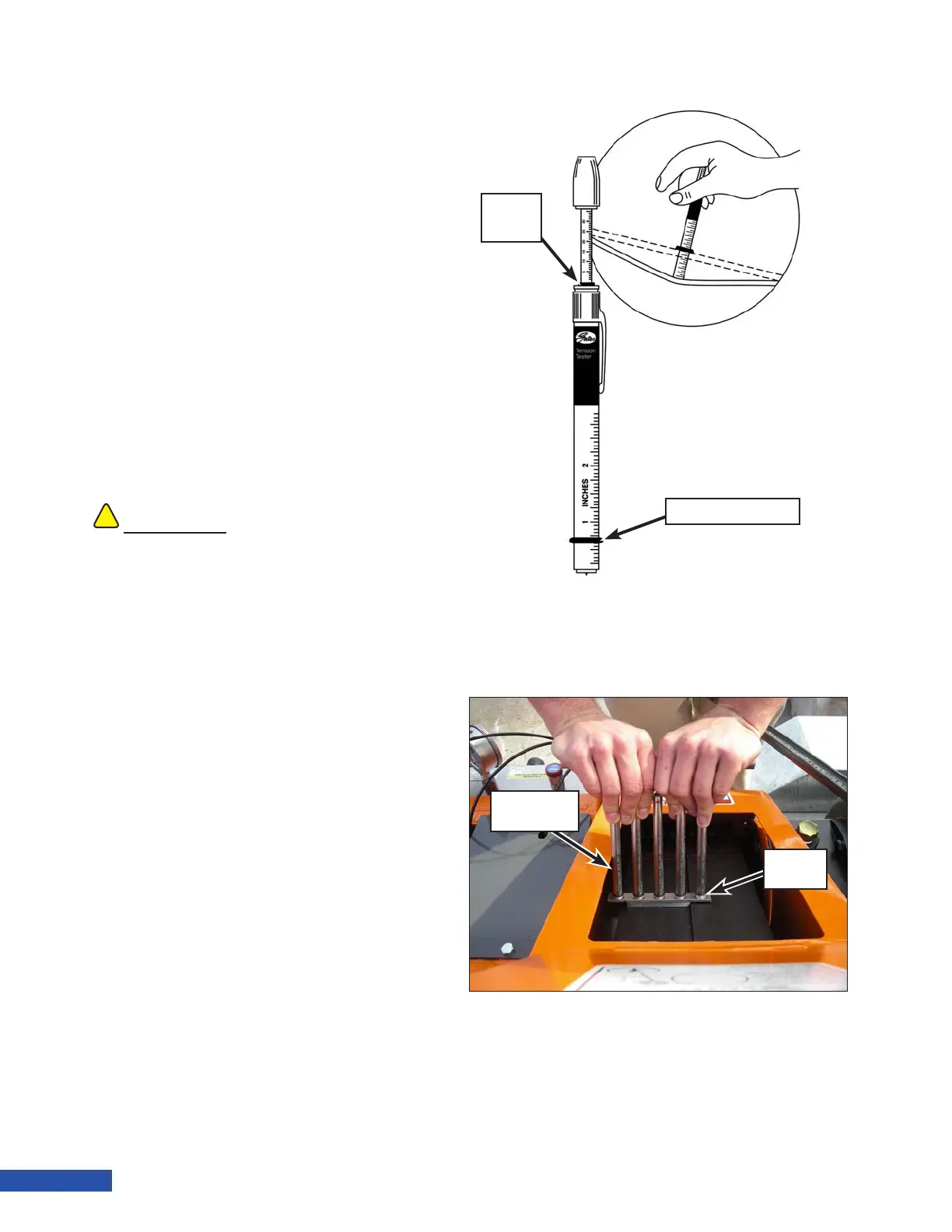

Slide the force O-ring to the bottom of

the scale. Use a ve barrel tension tool if

power bands are used on your unit (Figure

138).

5. Position the tension tool in the middle

of one of the belts mid-way between belt

pulleys. Press on the tool until the deec-

tion O-ring is even with the adjacent belt.

On ve barrel tensioners, press until the

gauge plate (Figure 138) touches the adja-

cent belt.

Note: Power bands are ve times the

single belt force.

6. Release pressure and inspect the reading

at the bottom edge of the force O-ring(s)

(Figure 137) on the tension tool. Adjust the

!!

CAUTION

Belts must be adjusted properly. Improper

adjustment can lead to belt slippage and failure,

or PTO bearing damage caused by excessive belt

tension.

Figure 137: Single Belt Tension Tester.

Deflection O-Ring

Force

O-Ring

Figure 138: Power Band Tensioning

Gauge

Plate

Five Barrel

Tensioner

Loading...

Loading...