RWF II ROTARY SCREW COMPRESSOR UNITS

OPERATION

070.610-IOM (JUN 11)

Page 22

and/or heat tracing of the compressor lube oil systems is

highly recommended.

When low ambient temperatures (below +20°F) are a pos

sibility, it is recommended that lube oil lines, oil lters, oil

pumps, and oil coolers be heat traced and insulated.

Freezeup protection must also be provided for all water

cooled equipment

SUCTION CHECK VALVE

POWER ASSIST KIT

Low temperature booster compressor applications require

hot gas to assist the suction check valve closure for RWF II

models 496, 676, 856, and 1080. This is accomplished by using

the high pressure discharge gas from the high pressure side

of the system (power assist kit).

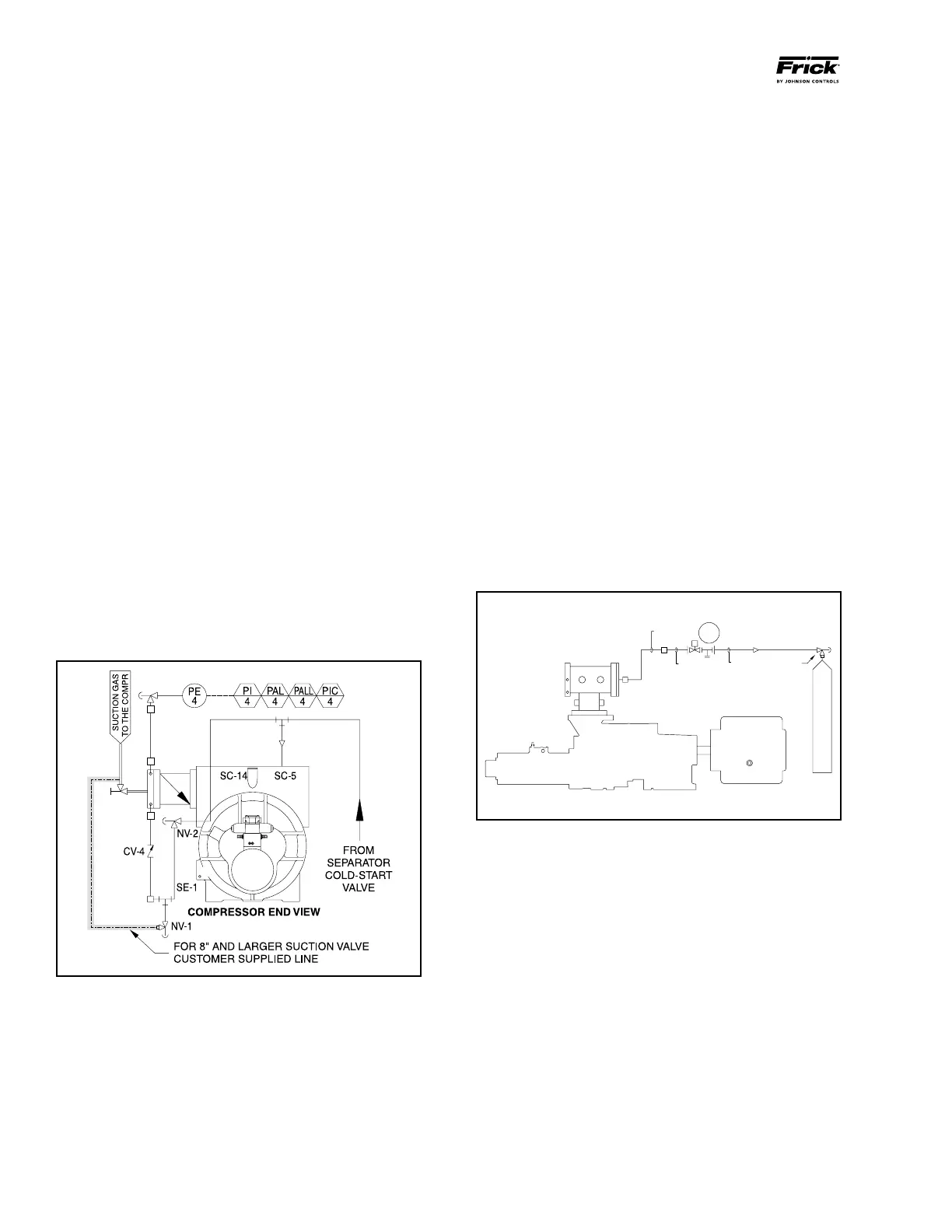

The power assist kit (Figure 28) is factory installed with the

discharge gas pressure being supplied from the high stage

discharge gas. The kit consists of a strainer, mounted and

wired solenoid valve, timer, and metering valve. The timer

limits the high pressure gas feed to the suction check valve

to thirty seconds via the solenoid valve. This is sufcient

time to warm the suction check valve piston and provide

proper operation. The metering valve is provided for use as

a service valve and to allow discharge gas ow regulation to

prevent excessive force and resulting closure "hammering".

The valve should be adjusted accordingly to prevent such

an occurrence.

POWER ASSIST TO BE CONNECTED TO

CONN IN CENTER OF MV END PLATE

HIGH PRESSURE GAS FROM HIGH

SIDE COMPRESSOR DISCHARGE

M–1

C–1

3/8 OD

1/2

1/2

1/4

STR-4

S

YY

7

Figure 28 - Power Assist Kit

BALANCE PISTON PRESSURE REGULATOR

A Balance Piston Pressure Regulator may be required on

Models 496 – 1080 to reduce the extended overbalance from

the thrust balance piston at part load.

High-Stage SB-2 Oil Supply Line Diagram, Figure 29, shows

the three additions described below arranged in parallel.

PRESSURE-REGULATING VALVE: Discharge pressure deter

mines compressor thrust balance. The proper setting for the

pressureregulating valve is 50 psi (±15) below DISCHARGE

pressure when slide valve is less than 65%.

SOLENOID VALVE: Energizing, or opening, the solenoid valve

pressurizes the balance piston with full oil pressure from the

oil manifold, bypassing the A4ALE Pressure Regulating Valve.

Deenergizing, or closing, the solenoid valve pressurizes

the balance piston with oil pressure regulated by the A4ALE

Pressure Regulating Valve.

3. Connect the power supply.

4. Release down arrow and up arrow push buttons.

5. When the display on ICAD (Figure 22) is alternating be

tween showing: CA and A1 the factory resetting is complete.

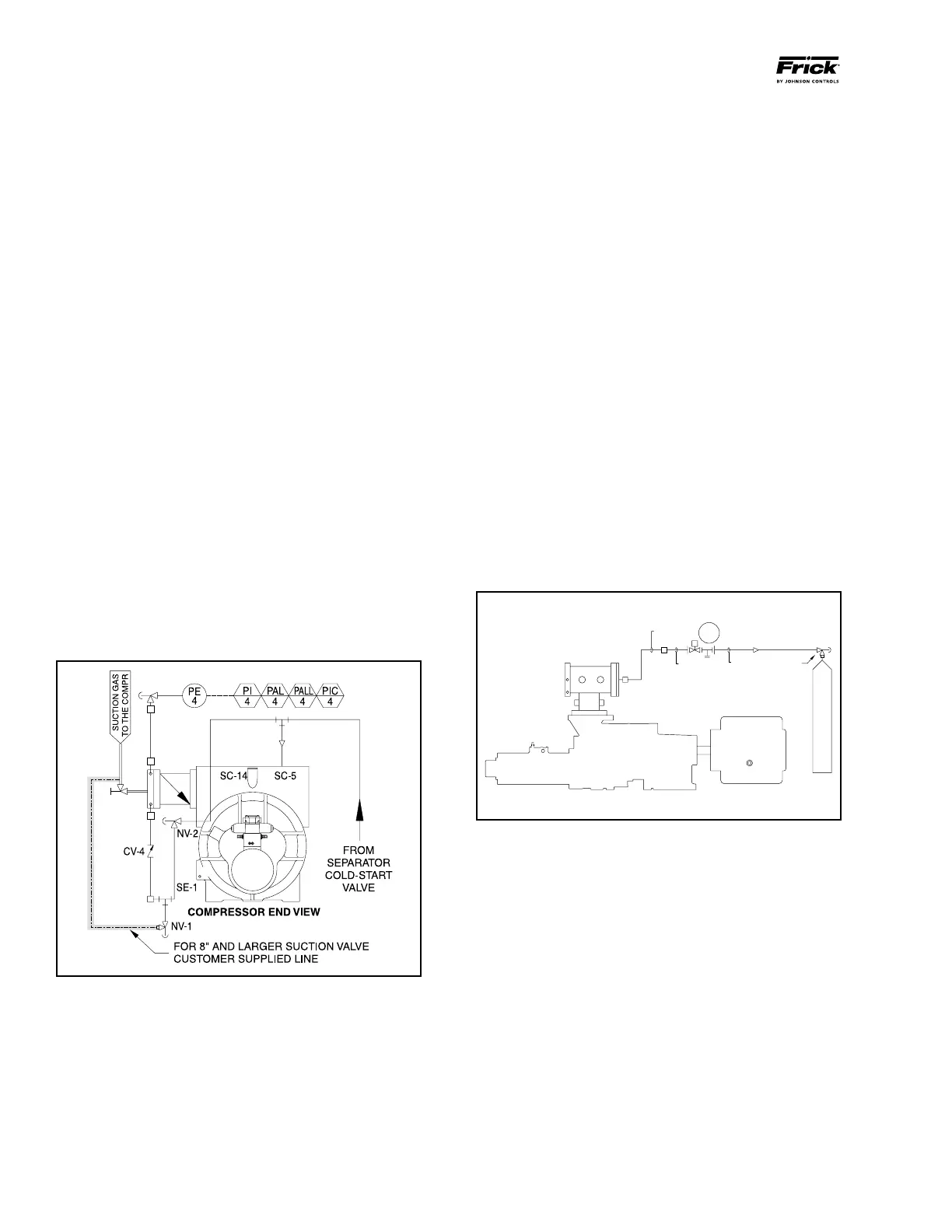

SUCTION CHECK VALVE BYPASS

The RWF II unit is equipped with a lowpressuredrop suc

tion check valve bolted directly to the compressor housing.

Units that have an 8" stop valve or larger should be piped as

shown in the shaded area of Figure 27. During normal opera

tion, valve NV1 is closed. This is a pumpout connection

to allow refrigerant removal to the system suction prior to

evacuation for servicing. Valve NV2 must be open in most

systems at all times. It should normally be cracked open to

allow the oil separator to slowly bleed down to approxi-

mately system suction pressure when the unit is stopped

(having this valve cracked open allows the compressor drive

motor to have an easier start, and the discharge check valve

will seat more tightly). If the drive coupling backspins, start

closing the valve until the backspin stops. If the separator oil

level foams excessively on shutdown, NV2 should be closed

slightly. If the separator takes more than 20 – 30 minutes to

equalize to suction pressure after shutdown, NV2 can be

opened slightly. See Figure 27.

Check valve CV4 is installed on all RWF II packages. On

highstage systems, check valve CV4 is installed with a

45 psi spring to avoid the possibility of backfeeding to a

shutdown compressor from a common economizer vessel.

On booster systems, check valve CV4 is installed with a

25 psi spring to avoid the possibility of air ingress into the

system, if the system suction pressure is below atmospheric.

Figure 27 - Suction Check Valve Bypass

LOW AMBIENT OPERATION

It is recommended that oil separators be insulated as a

minimum requirement to preserve the heat generated by

the oil heaters. It is important that the coalescer end of the

separator be insulated to prevent refrigerant condensation.

On systems located outdoors or in unheated buildings where

the ambient temperature could drop below +40°F, insulating

Loading...

Loading...