RWF II ROTARY SCREW COMPRESSOR UNITS

OPERATION

070.610-IOM (JUN 11)

Page 23

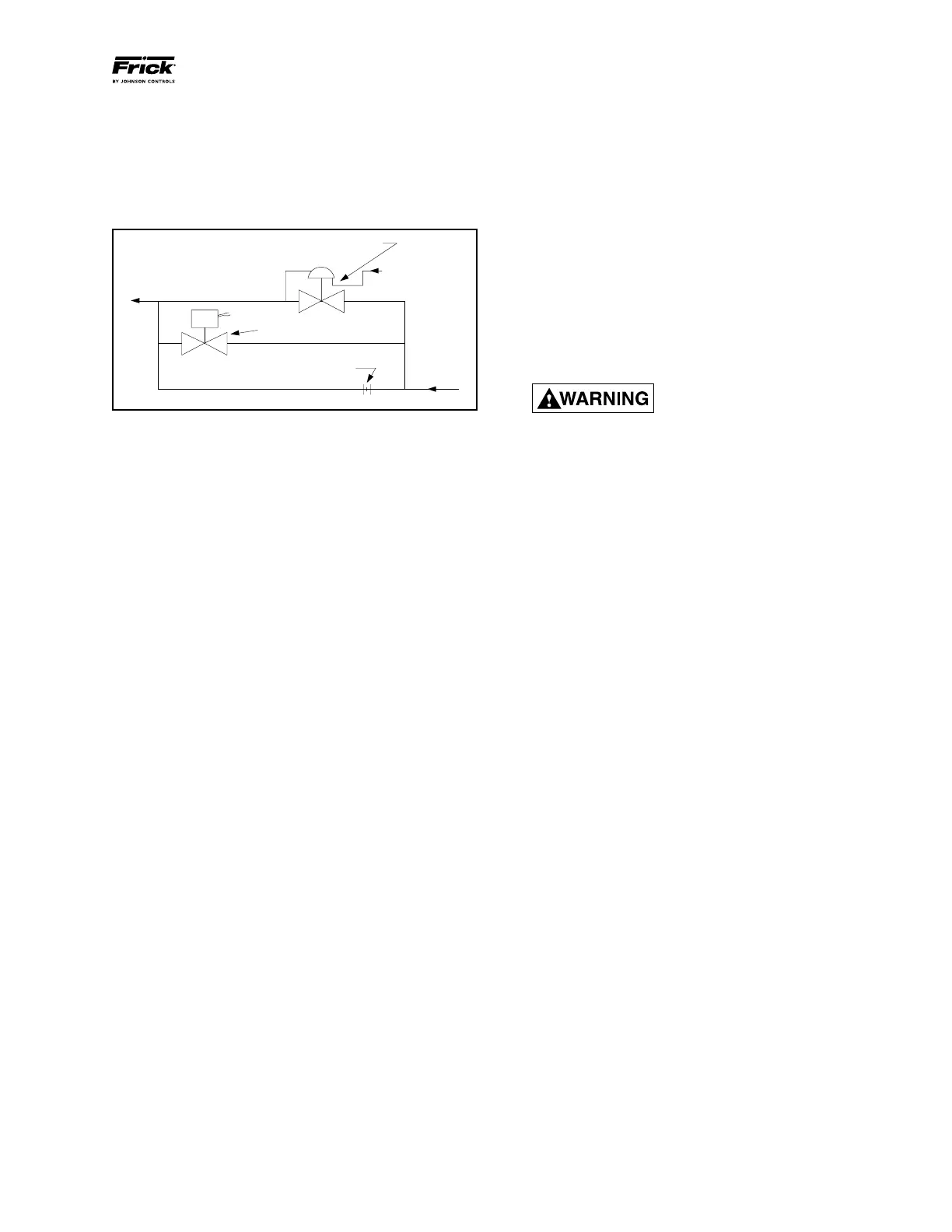

Signals from the control panel operate the solenoid valve

(output module 12 on micro panel). The solenoid valve should

open when the slide valve position is 70% or greater, and

close when the slide valve position is 65% or less.

ORIFICE: The orice ensures oil supply to the inlet end bear

ings during upset conditions such as startup.

534B0325H01 1/8" RESTRICTION ORIFICE

951A0007H01 (OR H03)

SOLENOID VALVE

TO SB-2

COMPRESSOR

PORT

954A0014H01 PRESSURE-REGULATING VALVE (A4ALE)

FROM

COMPRESSOR

DISCHARGE OR

OIL MANIFOLD

BLPSPREG

FROM OIL

MANIFOLD

Figure 29 - High-Stage SB-2 Oil Supply Line Diagram

INITIAL START-UP

Initial start-up must be performed under the super vision

of a Johnson Controls-Frick authorized start-up represen-

tative to prevent voiding the compressor warranty. Prior

to the start-up, the prestart check must be accomplish ed.

See Prestart Checklist in the Forms section of this manual.

INITIAL START-UP PROCEDURE

Having performed the checkpoints on the prestart check

list (see FORMS section), the compressor unit is ready for

startup. It is impor tant that an adequate refrigerant load

be available to load test the unit at normal operating condi

tions. The following points should be kept in mind during

initial startup.

1. It is imperative that during the initial start-up of the

package that the hand expansion valve on the main oil

injection line is fully open to ensure adequate oil ow.

There is still an orice installed in the compressor to control

maximum oil ow. At initial startup of the package the hand

expansion valve must be fully open. After initial startup of

the package the hand expansion valve should be adjusted.

There are two methods of determining the correct adjust

ment of this valve.

The best method to determine target discharge temperature

is to run CoolWare™ with the operating conditions of the

compressor. The program will give you a theoretical discharge

temperature of the compressor. Once this temperature is

known, you may adjust the hand expansion valve. The ideal

discharge temperature is within 5°F + or – of the theoretical

discharge temperature. Adjust the valve to achieve the theo

retical discharge temperature. If you do not have access to

CoolWare™, 180°F is a good target discharge temperature for

a high stage ammonia compressor. Booster applications and

compressors using HFC and HCFC refrigerants may run cooler.

Compressors with high discharge pressure may run hotter.

The rst method is used for compressors with External Oil

Cooling (Thermosyphon, Water Cooled, and Glycol Cooled).

Before the initial startup of the compressor close the hand

expansion valve completely. Open the valve back up and

count the turns that it takes to fully open the valve. After

the initial startup close the valve to achieve approximately

180° F discharge temperature or the theoretical temperature

from CoolWare. Do not fully close the valve at any time while

the compressor is running.

The second method is used for compressors with Liquid

Injection Oil Cooling. Because the discharge temperature is

controlled by the Liquid Injection Thermal Expansion Valve

you will not be able adjust for the correct oil ow by using

the discharge temperature. Before the initial startup of the

compressor close the hand expansion valve completely. Open

the valve back up and count the turns that it takes to fully

open the valve. After the initial startup close the valve ½

way. If it took 10 turns to open the valve completely, then

turn it in 5 turns. If it took 7 turns to open, then close the

valve 3½ turns. Do not close the valve any further than ½

the number of turns required to fully open it.

Failure to properly adjust this valve

can lead to excessive noise and

vibration of the compressor and

package, premature failure of the bearings, liquid loading

of the rotors, liquid starvation of the rotors and cata-

strophic failure of the compressor.

2. For proper and safe operation, the compressor must be

run at the proper speed and discharge pressure. Exceeding

design conditions creates a potential hazard.

3. Rotate and lubricate motor bearings according to manu

facturer’s recommendations PRIOR to initial startup as

required.

4. After running the unit for approximately three hours, ad

just liquid injection oil cooling if applicable. If unit has water

cooled oil cooling, adjust water control valve to cooler.

5. The compressor slide valve and slide stop linear transmit

ters should be calibrated.

6. Perform vibration analysis if equipment is available.

NORMAL START-UP PROCEDURE

1.

Conrm system conditions permit starting the compres sor.

2. Press the [RUN] key.

3. Allow the compressor to startup and stabilize. Press the

[AUTO] key immediately below the V ratio label on the oper

ating display screen. Press the [AUTO] key im mediately below

the SV POS label on the operating display. The compres sor

is now operating in the automa tic mode.

4. Observe the compressor unit for mechanical tightness of

the external piping, bolts and valves. Ensure that the ma

chine is clean from oil and refrigerant leaks. If any of these

occur, shut down the compressor and correct the problem

as necessary using good safety precautions.

5. RETIGHTEN MANWAY BOLTS at condenser design

pressure (while system is running).

RESTARTING COMPRESSOR UNIT AFTER CONTROL

POWER INTERRUPTION (PLANT POWER FAILURE)

1. Check variable setpoints.

2. Follow normal startup procedure.

Loading...

Loading...