RWF II ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

070.610-IOM (JUN 11)

Page 31

oil foaming, nuisance oil level cutouts, oil pressure loss,

gas or oil leakage and catastrophic compressor failure.

NOTE: The Frick

®

oil charge shipped with the unit is the

best suited lubricant for the conditions specied at the

time of purchase. If there is any doubt due to the refriger-

ant, operating pressures, or temperatures, refer to Frick

®

Oil publication 160-802 SPC for guidance.

1. Only use Frick

®

oil lter elements or warranty claim

may be denied.

2. Participate in a regular, periodic oil analysis program to

maintain oil and system integrity. Oil Analysis Kit part number:

333Q0001853.

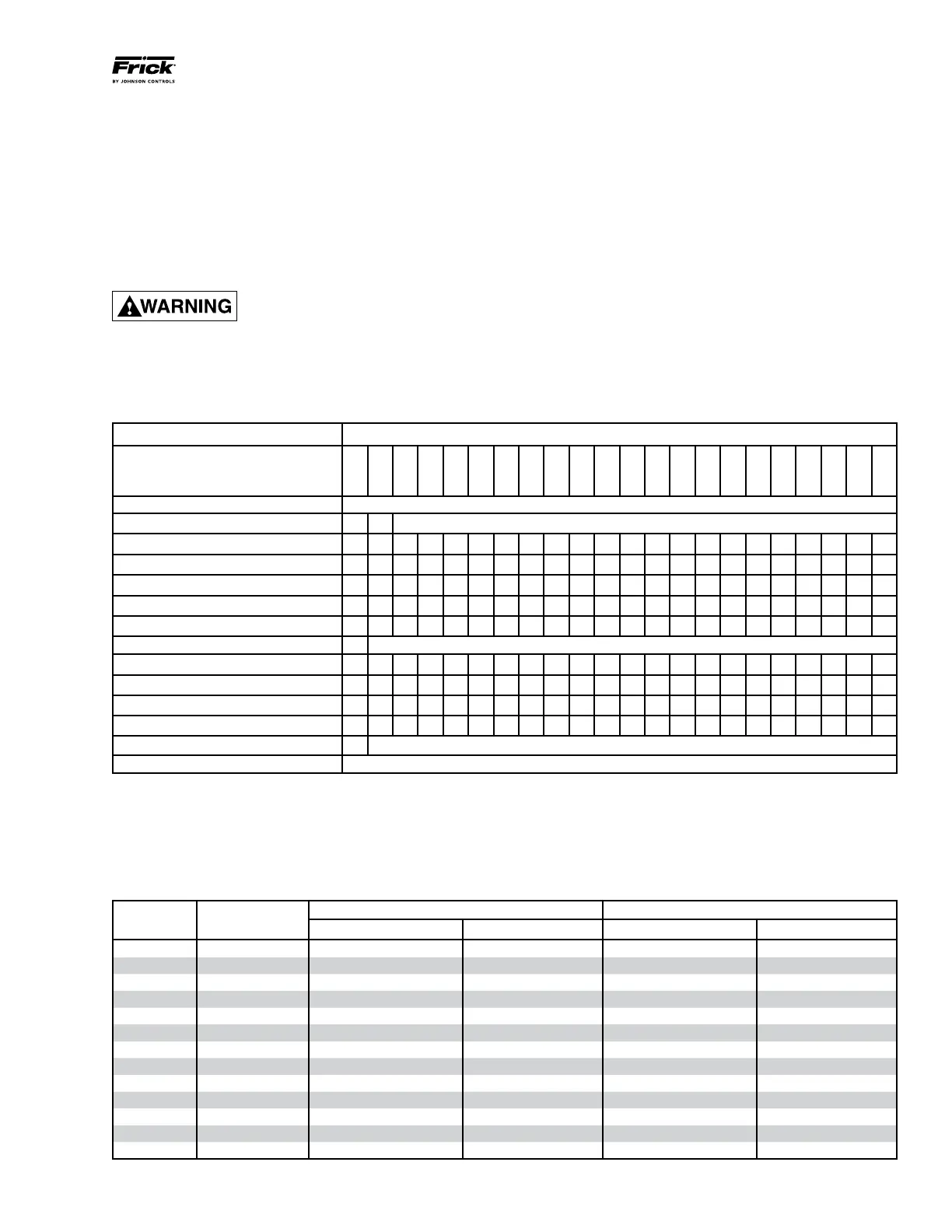

MAINTENANCE SCHEDULE

This schedule should be followed to ensure troublefree operation of the compressor unit.

4. Vibration readings can be inuenced by other equip ment

operating in the vicinity or connected to the same piping as

the unit.

OIL QUALITY AND ANALYSIS

High quality refrigeration oil is necessary to ensure compres

sor longevity and reliability. Oil quality will rapidly deteriorate

in refrig eration systems containing moisture and air or other

contaminants. In order to ensure the quality of the refrigera

tion oil in the com pressor unit.

DO NOT MIX OILS of different

brands, manufacturers, or types.

Mixing of oils may cause excessive

a. Check bolts, shim packs, center inserts, keys, and all bolt torques.

b. Check and torque all terminals in the processor and starter panel per the specication posted in the enclosure.

c. Check calibration of Slide Valve, Slide Stop, pressures and temperatures. Calibration should be conducted with NIST certied devices.

d. Verify tightness of bolts on suction and discharge anges. See table below for torque requirements.

e. Vibration measurement must be carried out continuously to obtain optimum preventative control on bearings. If not continuously

controlled, then every 6 months, more frequently if levels increase.

f. Units with varible speed drives check for excess vibration and skip frequencies anytime unit operating conditions change.

FREQUENCY OR HOURS OF OPERATION (MAXIMUM)

MAINTENANCE

200

1000

5000

8000

10,000

15,000

20,000

25,000

30,000

35,000

40,000

45,000

50,000

55,000

60,000

65,000

70,000

75,000

80,000

85,000

90,000

95,000

Change Oil As Directed By Oil Analysis

Oil Analysis

n

Every 6 Months

Replace Filters

n

n

n

n

n

n

n

n

n

n

n

Clean Oil Strainers

n

n

n

n

n

n

n

n

n

n

n

Clean Liquid Strainers

n

n

n

n

n

n

n

n

n

n

n

Replace Coalescers

n

n

n

Check and Clean Suction Strainer

n

n

n

n

n

n

n

n

n

n

n

Check Coupling (a)

n

Annually Regardless of Operating Hours

Suction & Disch Flange Bolts (d)

n n n n n n n n n n n n n n n n n n n n n n

VFD Units Check Skip Freq. (f)

n n n n n n n n n n n n n n n n n n n n n n

Check Electrical Connections (b)

n n n n n n n n n n n n n n n n n n n n

Check Sensor Calibration (c)

n n n n n n n n n n n n n n n n n n n n n

Vibration Analysis (e)

n

Every 6 Months, More Frequently If Levels Increase

Replace Shaft Seal When Leak Rate Exceeds 7 8 Drops Per Minute

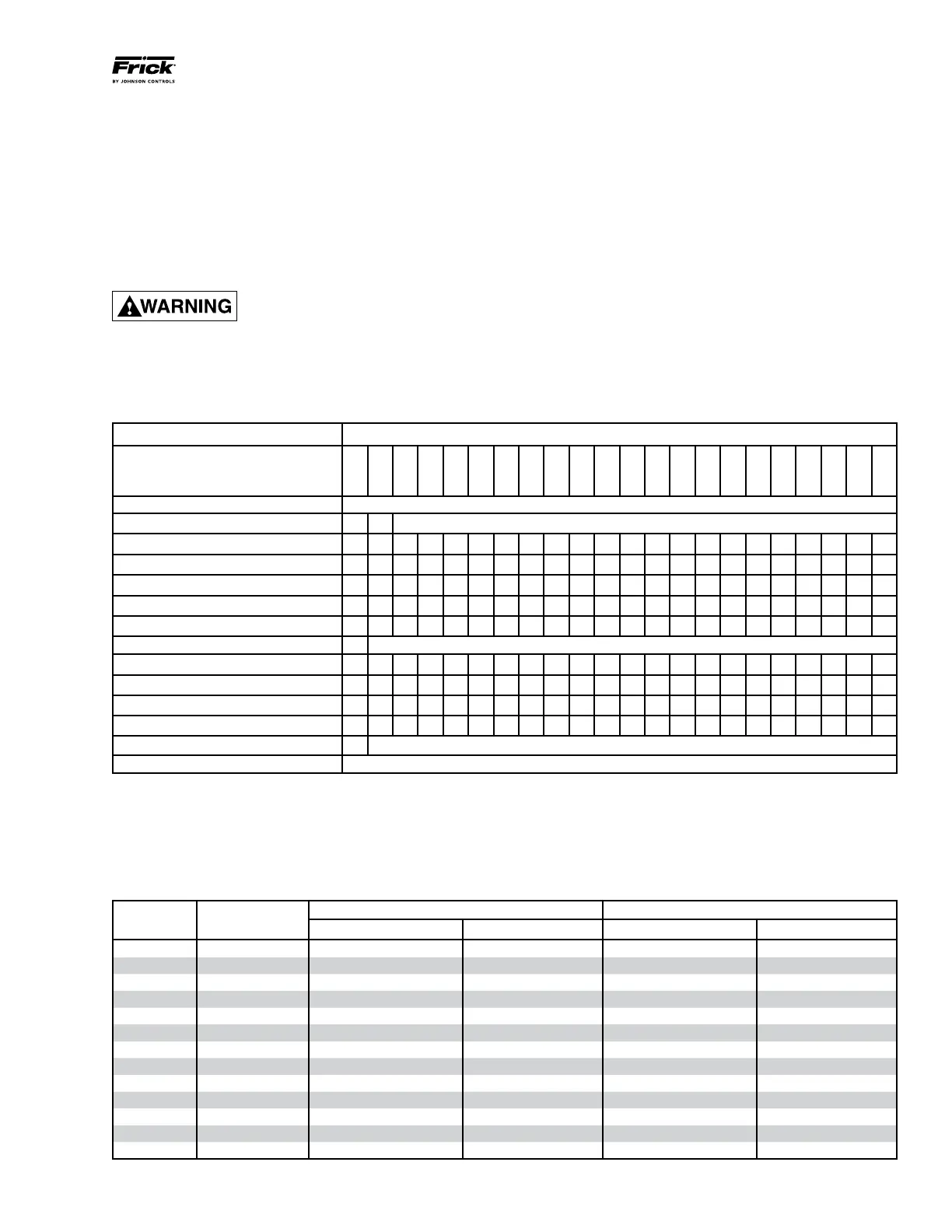

RWF II

MODEL

Compressor

Model

Discharge Flange to Separator Flange Suction Flange

Bolt Size Torque* (ft-lb) Bolt Size (in.) Torque* (ft-lb)

100 SGC 1913 M20 X 2.5 140 M20 X 2.5 180

134 SGC 1918 M20 X 2.5 140 M20 X 2.5 160

177 SGC 2313 M20 X 2.5 160 M20 X 2.5 160

222 SGC 2317 M20 X 2.5 160 M20 X 2.5 200

270 SGC 2321 M20 X 2.5 160 M22 X 2.5 220

316 SGC 2813 M22 X 2.5 230 M22 X 2.5 220

399 SGC 2817 M22 X 2.5 230 M22 X 2.5 220

480 SGC 2821 M22 X 2.5 230 M24 X 3.0 220

496 SGC 3511 M24 X 3.0 240 M30 X 3.5 350

546 SGC 2824 M22 X 2.5 240 M24 X 3.0 220

676 SGC 3515 M24 X 3.0 240 M30 X 3.5 350

856 SGC 3519 M24 X 3.0 240 M30 X 3.5 350

1080 SGC 3524 M24 X 3.0 240 M30 X 3.5 350

* Based on: GasketsGarlock

®

BlueGard

®

3300; Boltsclass 8.8 or stronger hex head bolts, lightly oiled and clean

Loading...

Loading...