RWF II ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

070.610-IOM (JUN 11)

Page 10

ECONOMIZER - HIGH STAGE (OPTIONAL)

The economizer option provides an increase in system capac

ity and efciency by subcooling liquid from the condenser

through a heat exchanger or ash tank before it goes to the

evapora tor. The subcooling is provided by ashing liquid in

the economizer cooler to an intermediate pressure level. The

intermediate pressure is provided by a port located part way

down the compres sion process on the screw compressor.

As the screw compressor unloads, the economizer port will

drop in pressure level, eventually being fully open to suc

tion. Because of this, an output from the microproces sor is

generally used to turn off the supply of ashing liquid on a

shell and coil or DX economizer when the capacity falls be

low approximately 60%70% capacity (85%90% slide valve

position). This is done because the compressor will be more

efcient operating at a higher slide valve position with the

economizer turned off, than it will at a low slide valve posi

tion with the economizer turned on. Please note however

that shell and coil and DX economizers can be used at low

compressor capaciti es in cases where efcien cy is not as

important as assuring that the liquid supply is subcooled. In

such cases, the economi zer liquid solenoid can be left open

whenever the com pressor is running.

Due to the tendency of the port pressure to fall with de creasing

compressor capacity, a backpressure regulator valve (BPR) is

generally required on a ash economizer system (Figure 10) in

order to maintain some preset pressure dif ference between

the subcooled liquid in the ash vessel and the evaporato rs.

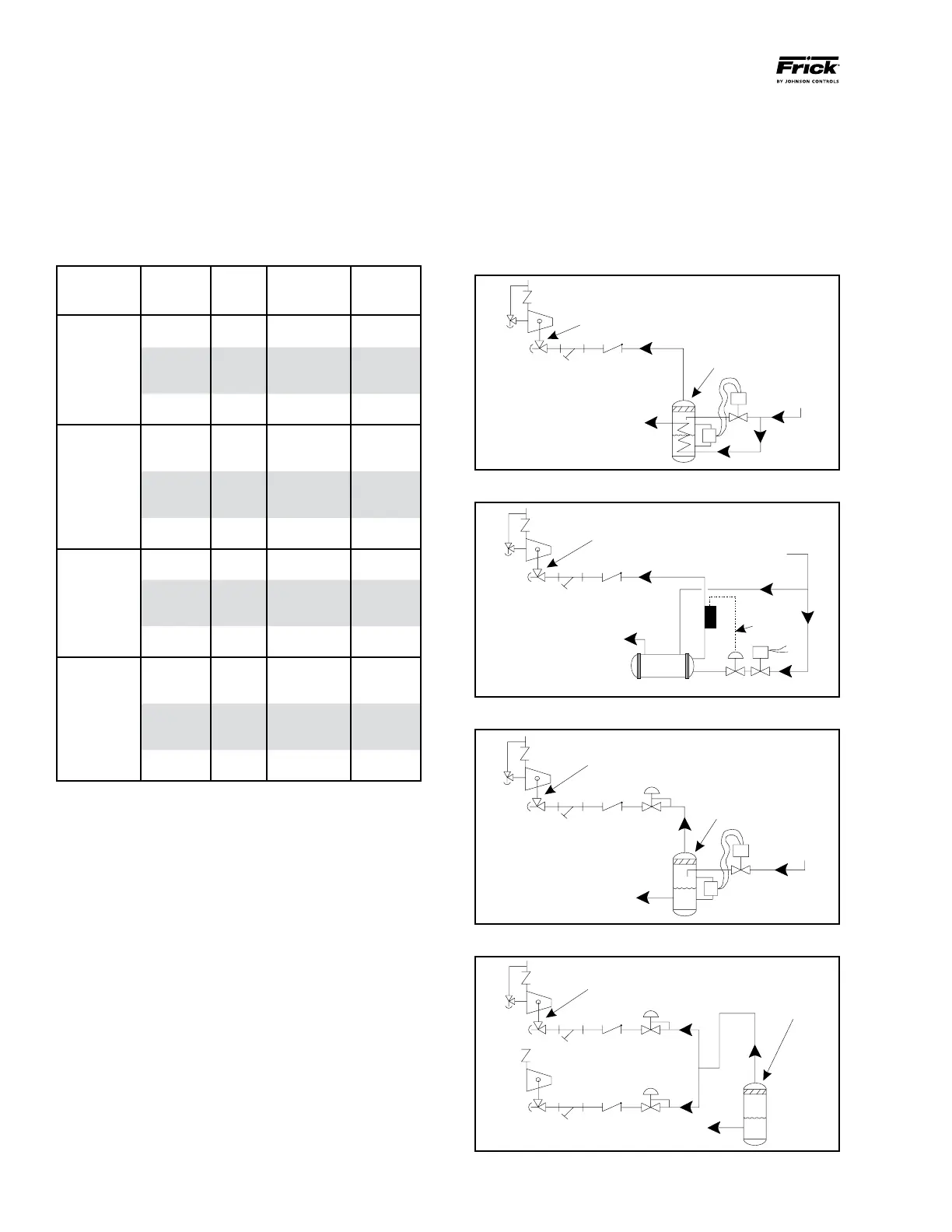

Figure 9 - Direct Expansion Economizer System

Figure 8 - Shell and Coil Economizer System

Figure 11 - Multiple Compressor Economizer System

Figure 10 - Flash Economizer System

HIGH

PRESSURE

LIQUID

INTERMEDIATE PRESSURE

GAS TO COMPRESSOR

SUCTION

STR

VCK

SUBCOOLED

HIGH PRESSURE

LIQUID TO

EVAPORATOR

ECONOMIZER

COOLER

ECON1

HV-2

HIGH

PRESSURE

LIQUID

INTERMEDIATE PRESSURE

GAS TO COMPRESSOR

SUCTION

STR

VCK

SUBCOOLED

HIGH PRESSURE

LIQUID TO

EVAPORATOR

ECONOMIZER

COOLER

WIRING

ECON2

HV-2

HIGH

PRESSURE

LIQUID

INTERMEDIATE PRESSURE

GAS TO COMPRESSOR

SUCTION

STR

VCK

CONTROLLED

PRESSURE

SATURATED LIQUID

TO EVAPORATOR

ECONOMIZER

VESSEL

BPR

ECON3

HV-2

INTERMEDIATE PRESSURE

GAS TO COMPRESSOR

SUCTION

STR VCK BPR

CONTROLLED PRESSURE

SATURATED LIQUID TO EVAPORATOR

ECONOMIZER

VESSEL

ECON4

HV-2

your local distributor, but they must be suitable for stainless

steel. The oil cooler may be cleaned in place by back ushing

with recommended solution for approximately 30 minutes.

After back ushing, rinse the heat exchanger with fresh water

to remove any remaining cleaning solution.

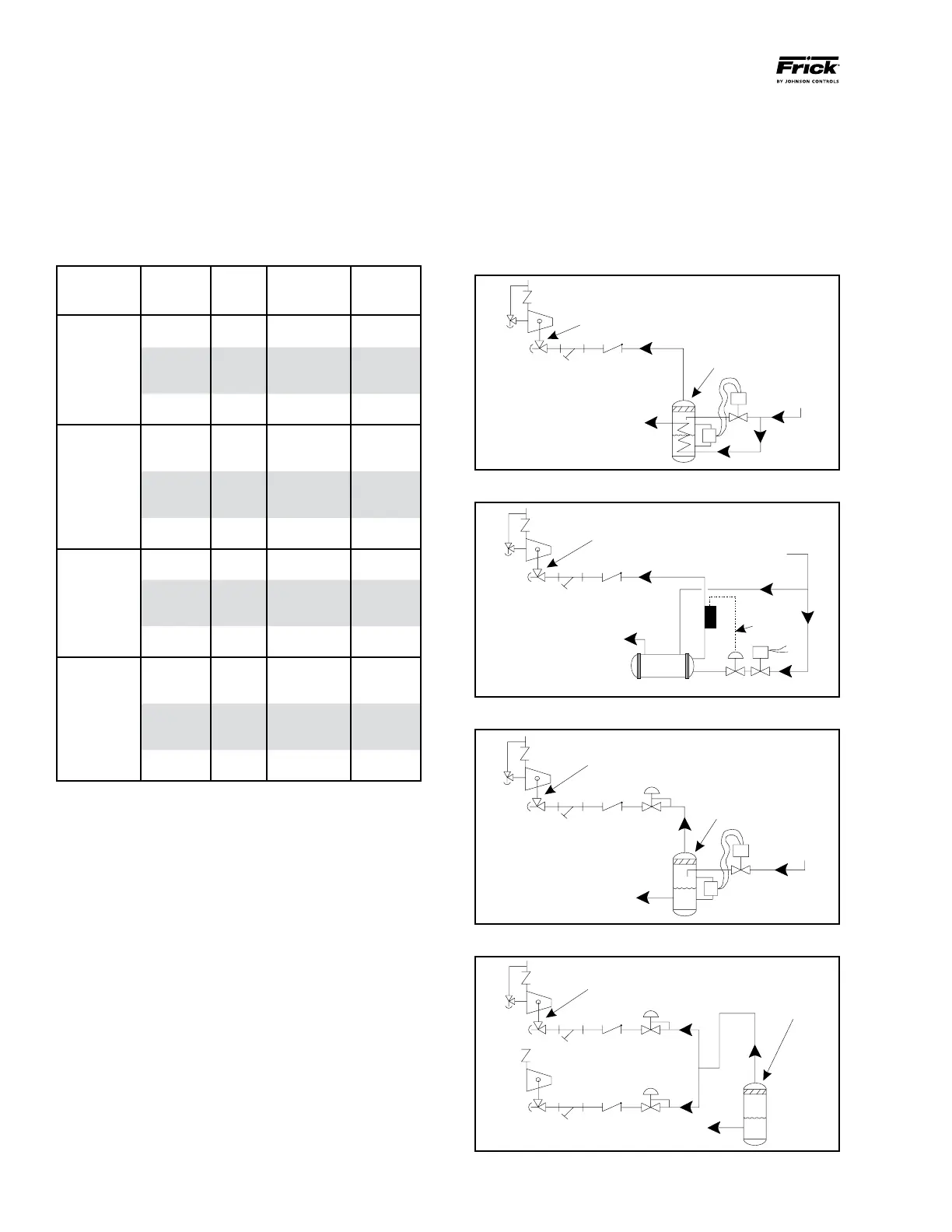

TABLE 1 - LIQUID LINE SIZE and RECEIVER VOLUME

CONDITIONS: Booster: 40°F Evap, 95°F Cond and 10°F

Intermediate; HI Stage: 0°F Evap, and 95°F Cond

PIPING

LINE

SIZE

POUND

PER MIN.

PER 5 MIN.

LIQUID

VOLUME

CU FT

REFRIG

RWF II

MODEL

R-717

High Stage*

100-134 1½ 81.0 2.2

177-270 2 132.0 3.6

316-480 3 236.5 6.4

496 3 305.0 8.3

546 3 323.5 8.8

676 4 417.0 11.4

856 4 532.0 14.5

R-717

Booster*

100-134 3/4 11.5 0.3

177-270 1¼ 17.0 0.4

316-480 1½ 31.0 0.8

496 1½ 38.5 0.9

546 1½ 42.5 1.0

676 2 54.0 1.3

856 2 69.5 1.7

1080 2 91.5 2.2

R-507

High Stage*

100-134 1¼ 229.0 3.7

177-270 2 370.5 6.0

316-480 2 664.0 10.7

496 2½ 878.5 14.1

546 2½ 908.5 14.6

676 3 1200.0 19.3

856 3 1243.0 20.0

R-507

Booster*

100-134 1/2 28.5 0.5

177-270 1/2 38.5 0.6

316-480 3/4 69.0 1.1

496 1 103.0 1.7

546 1 94.5 1.5

676 1¼ 141.5 2.3

856 1¼ 160.0 2.6

1080 2 336.0 5.4

* Based on 100 foot liquid line. For longer runs, increase line

size accordingly.

Loading...

Loading...