12

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

SECTION 1 - INSTALLATION

1. Place the cabinet in a horizontal position on the

oor adjacent to its installation location (when ris-

ers are attached to cabinet).

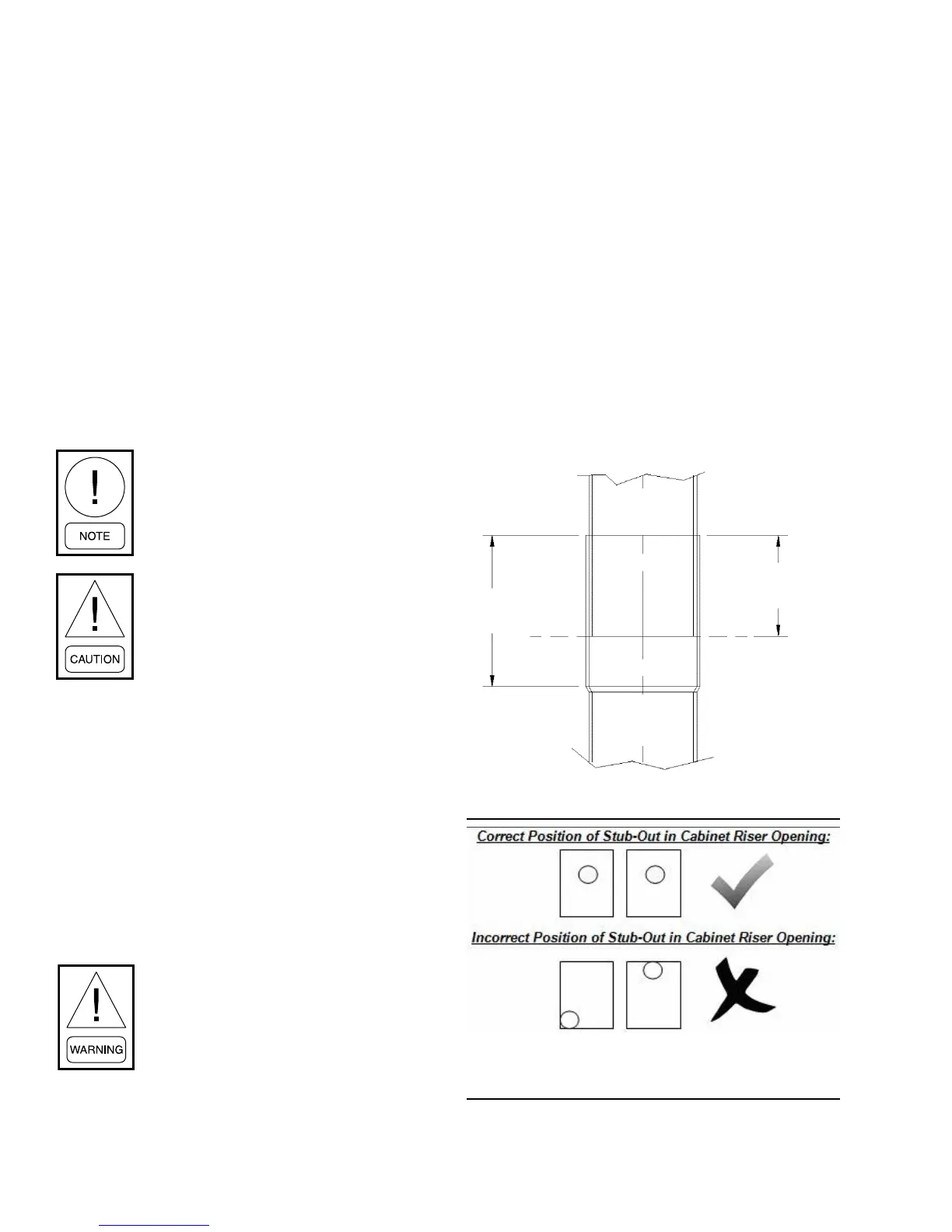

The units are designed to accommodate a maxi-

mum supply and return riser stub-out movement

of 1-1/2 inches due to expansion and contraction

(total movement of 3 inches). If the total calcu-

lated riser expansion or contraction exceeds 1-1/2

inches, the field must provide expansion compen-

sation.

2. Install eld or factory-provided riser extensions,

if required, to the unit-mounted risers prior to

moving the cabinet into nal position.

3. Raise the cabinet upright. Lower the risers through

the oor cutout, aligning the risers into the swaged

section of the unit on the oor below.

Take extra care not to scrape or dent ris-

ers during positioning. The riser tailpiece

should insert approximately 2 inches into

the 3-inch long swaged section of the unit

below.

DO NOT allow the riser tailpiece to bottom

out into the swaged section. This ensures

the correct riser positioning and com-

pensates for variations in oor-to-oor

dimensions.

4. Center the risers in the pipe chase, and level the

cabinet using shims as necessary.

5. Plumb risers in two planes to assure proper unit

operation and condensate drainage.

6. Anchor the cabinets into place using rubber iso-

lated sheet metal angles. Approved and tested

sheet metal angles are available from factory.

It is strongly recommended to install vibration

isolation pads to reduce noise transmission into

the floor. Failure to use isolation kits could result

in loud unit operation.

Do not drill or drive screws into the cabi-

net in the area of the internal drain pan.

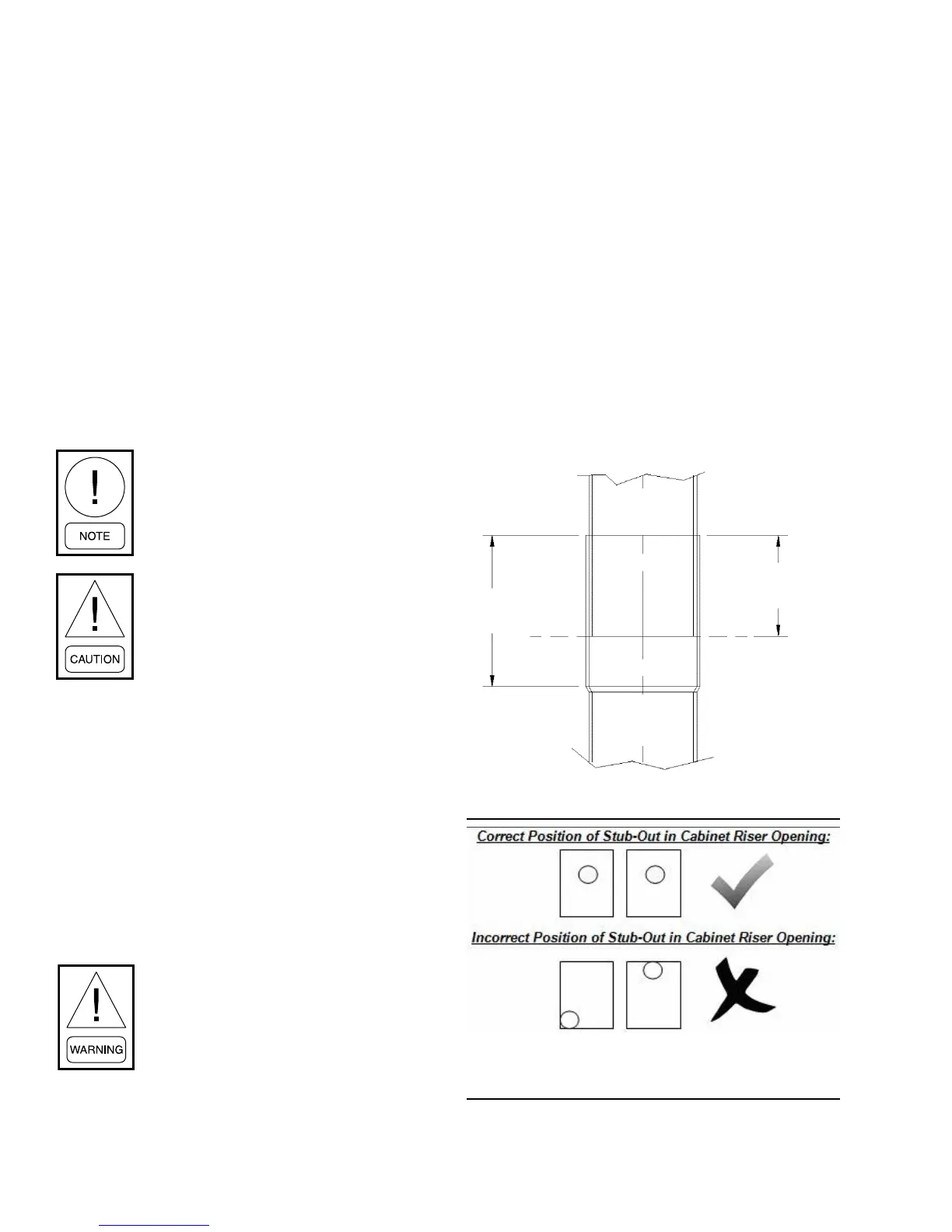

7. Center the risers’ horizontal stub-outs (complete

with factory-installed shut-off valves) in the cabi-

net slot openings. Ensure that the stub-outs are

perpendicular to the side/back panel.

8. Verify all risers are vertical and that they penetrate

the swaged joint at least 1 inch.

Factory provided risers come with a 3-inch deep

swage. Do not allow risers to completely bottom

out at 3 inches in the swage. The 3-inch swage

depth is oversized to allow for adjustments if nec-

essary to keep riser stub-outs and valves centered

in the cabinet opening.

9. Center the riser stub-out in cabinet opening to

allow for expansion and contraction. Riser stub-

outs must not contact on any sheet metal opening.

Otherwise damage can occur to stub-outs, result-

ing in water leaks and property damage.

Top Vertical

Riser

Bottom

Vertical Riser

2-inch Ideal

Insertion Depth

3-inch Cup

Height

LD23535

FIGURE 1 - IDEAL RISER INSERTION DEPTH

LD19017

FIGURE 2 - CORRECT/INCORRECT STUB-OUT

POSITIONS IN CABINET RISER OPENING

Loading...

Loading...