29

SECTION 1 - INSTALLATION

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

1

10. Continue to bleed the system until the water leav-

ing the drain is clear, no less than 2 hours.

11. Completely drain the piping system.

Cleaning the System

1. After the initial ushing, chemically clean the

system. Repeat the method in Flushing the System

on page 28 to rell the system and circulate the

cleaning solution.

It is recommended to use the services of a pro-

fessional water treatment company for the type of

solution to be used and the duration of the clean-

ing application.

2. Once the cleaning process is complete, shut off

the circulating pump and completely drain the

system.

3. Rell the system with clean water to prepare for

refrigeration chassis connection and system start-

up.

It is recommended that a professional wa-

ter treatment company perform ongoing

maintenance of the water loop including

chemical analysis and ushing, if neces-

sary. The water loop testing should be per-

formed at intervals recommended by the

professional water treatment consultant.

It is recommended that the water loop

testing be performed at least once a year.

Standard practice is once a month or

quarterly.

The customer is responsible for complet-

ing adequate water loop maintenance

over the lifespan of the units. Otherwise,

damage to the units may occur.

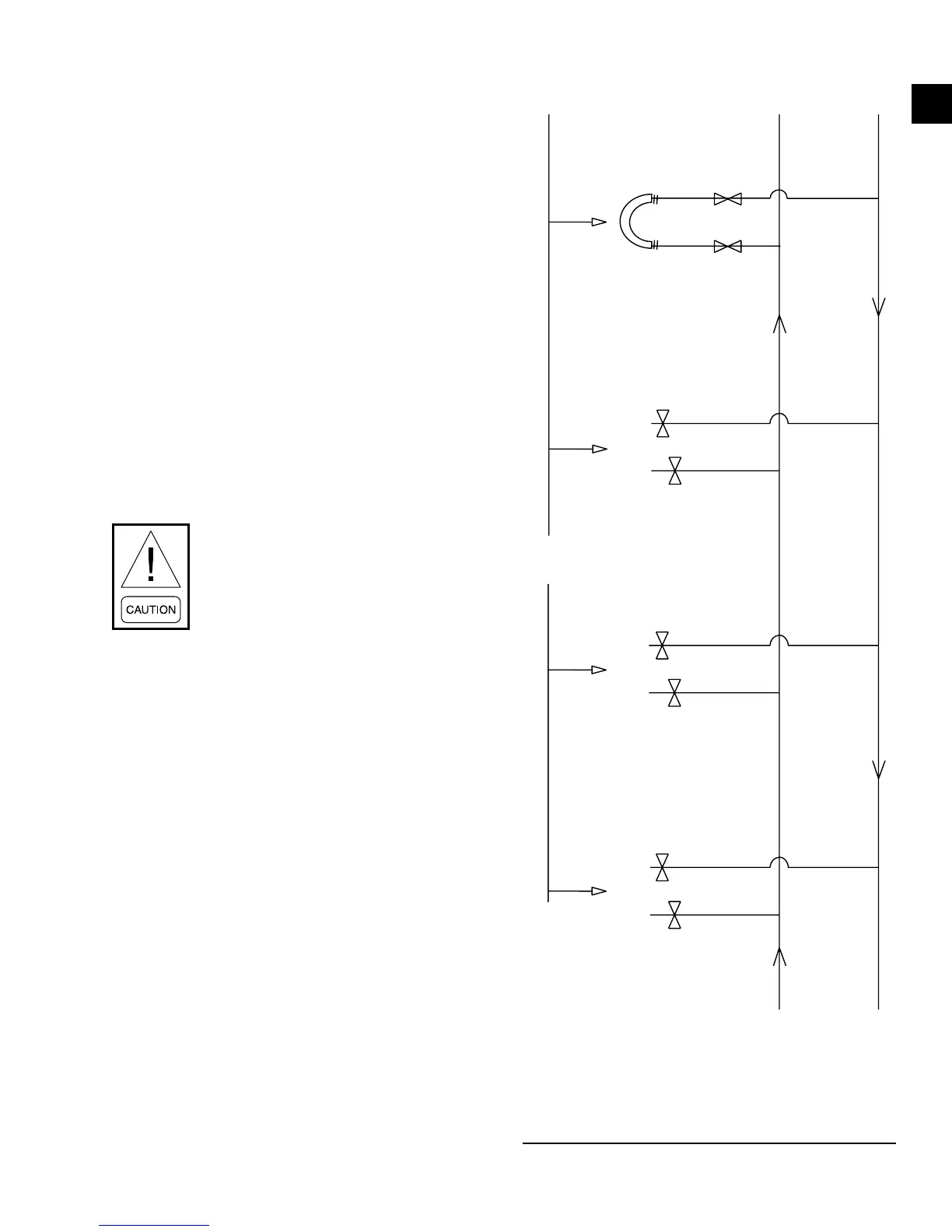

Stub-outs

connecting

supply & return

runouts

Supply

Hose or piping

connecting supply

and return runouts

Stub-outs to

chassis

Supply

Riser

Return

Riser

LD19685

FIGURE 20 - SYSTEM FLUSHING AND CLEANING

Loading...

Loading...