Conditioned based maintenance

Traditional chiller maintenance is based upon assumed and generalized conditions. Instead of

the traditional maintenance program, a Johnson Controls YORK Conditioned Based Maintenance

(CBM) program can be substituted. This CBM service plan is built around the specific needs for

the chiller, operating conditions, and annualized impact realized by the chiller. Your local Johnson

Controls Branch can propose a customized Planned Service Agreement that leverages real time and

historical data, delivering performance reporting, corrective actions required, and data enabled

guidance for optimal operation and life-cycle assurance. The program includes fault detection

diagnostics, operation code statistics, performance-based algorithms and advance rules-based

rationale delivered by the Johnson Controls Connected Equipment Portal.

Proactive services

Throughout the life of your chiller you can take proactive measures to help prevent breakdowns

and keep your unit in peak condition to prolong its lifespan. Proactive services are a smart addition

to your chiller care program, and supplement existing maintenance.

Time-based proactive services

A variety of factors, including unstable power, extreme ambient conditions, and chilled water

system issues can contribute to increased wear on certain unit components. To help ensure the

system remains reliable, you can replace these components at set intervals before significant wear

occurs. For detailed information on the specific time-based proactive services, along with other

proactive services, refer to YMC2 Centrifugal Liquid Chillers YORK Proactive Service Guide (Form 160.84-

PSG1).

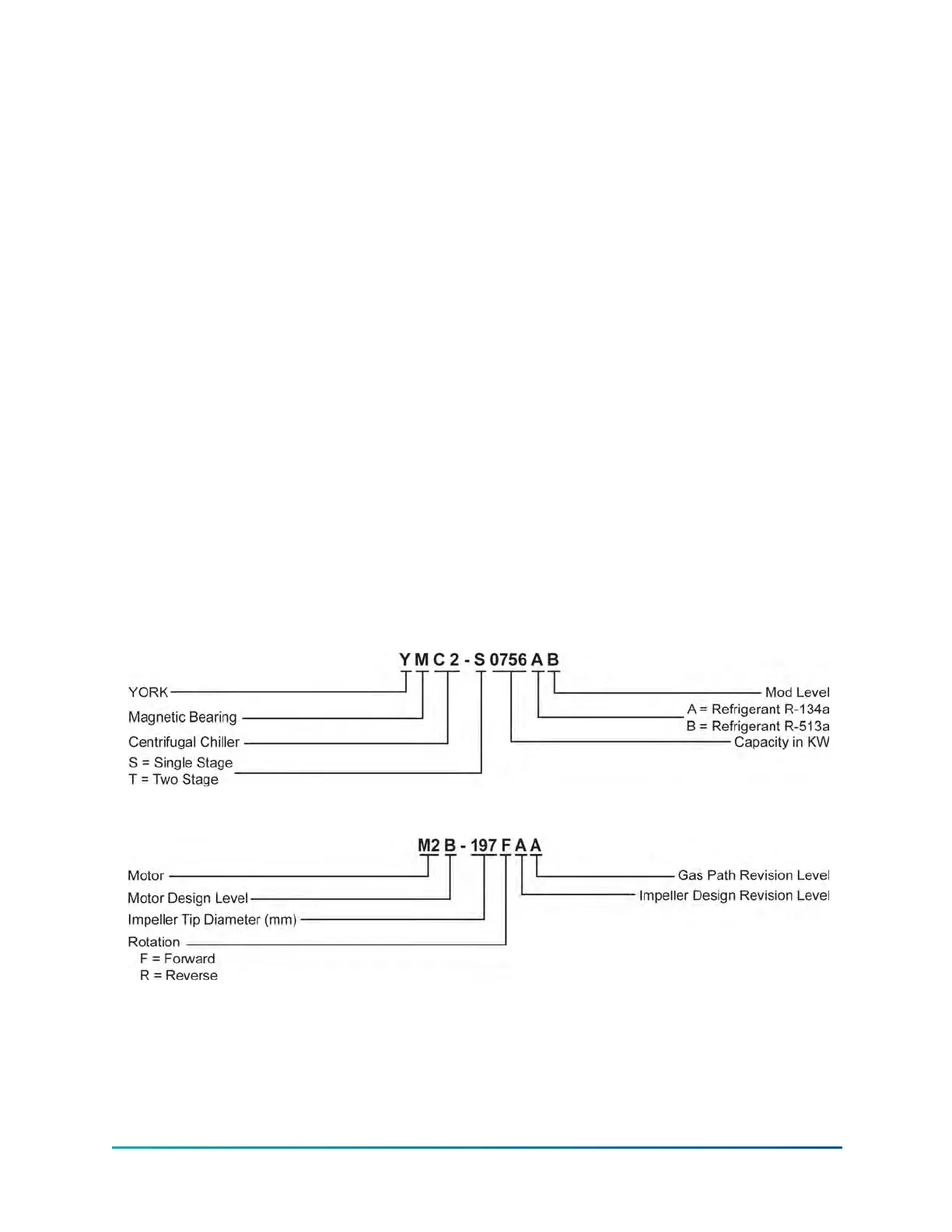

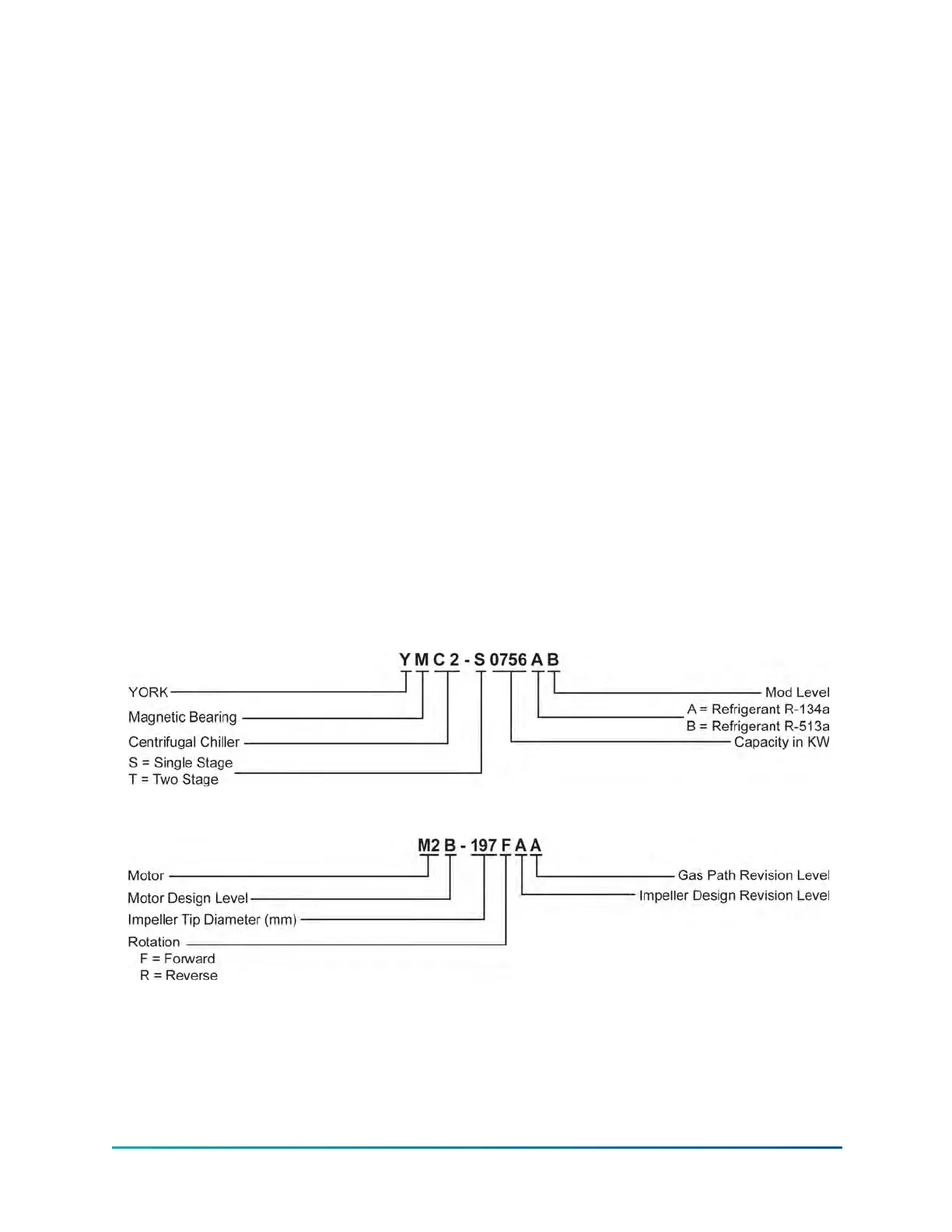

Nomenclature

Figure 2: System nomenclature

Figure 3: Compressor nomenclature

YMC

2

Mod B with OptiView Control Center

10

Loading...

Loading...