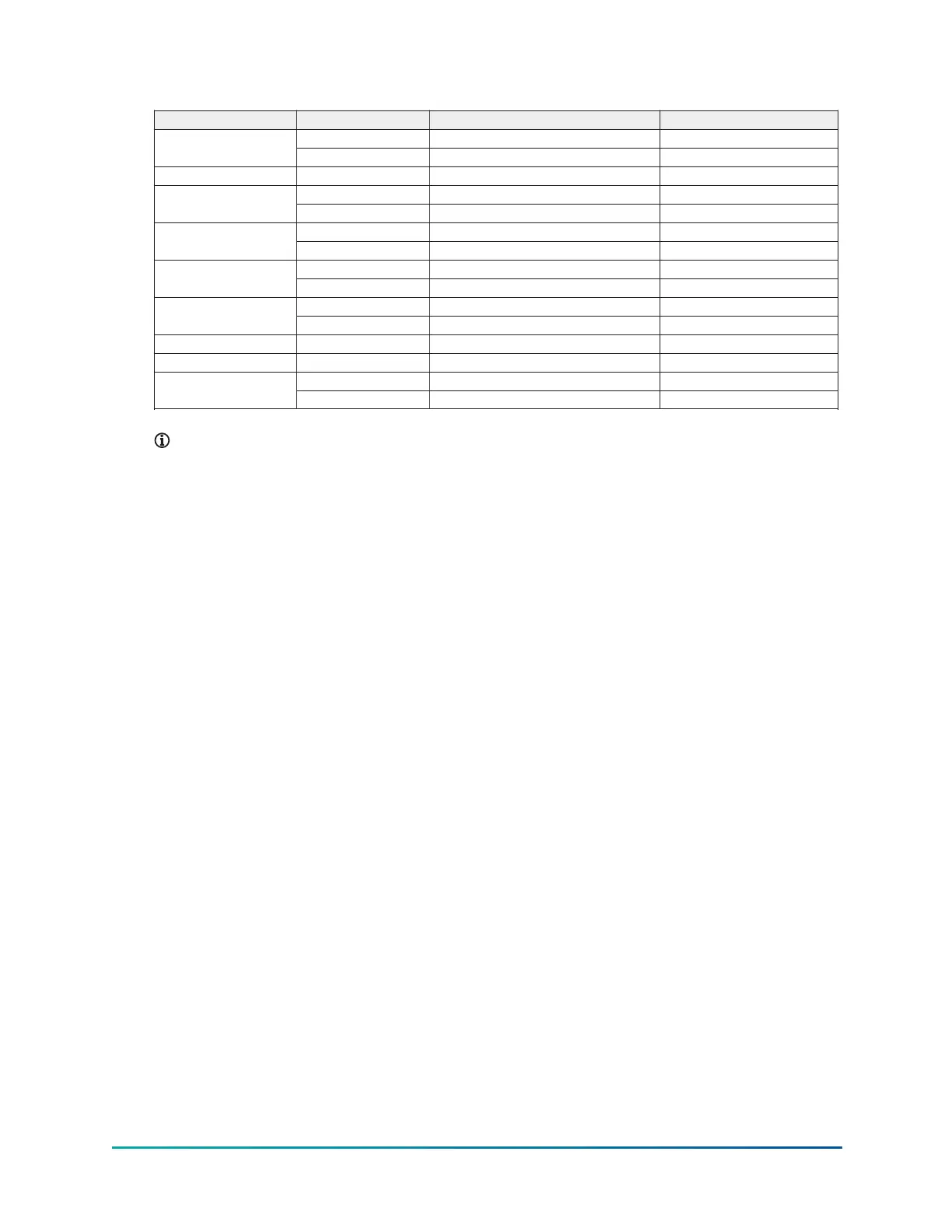

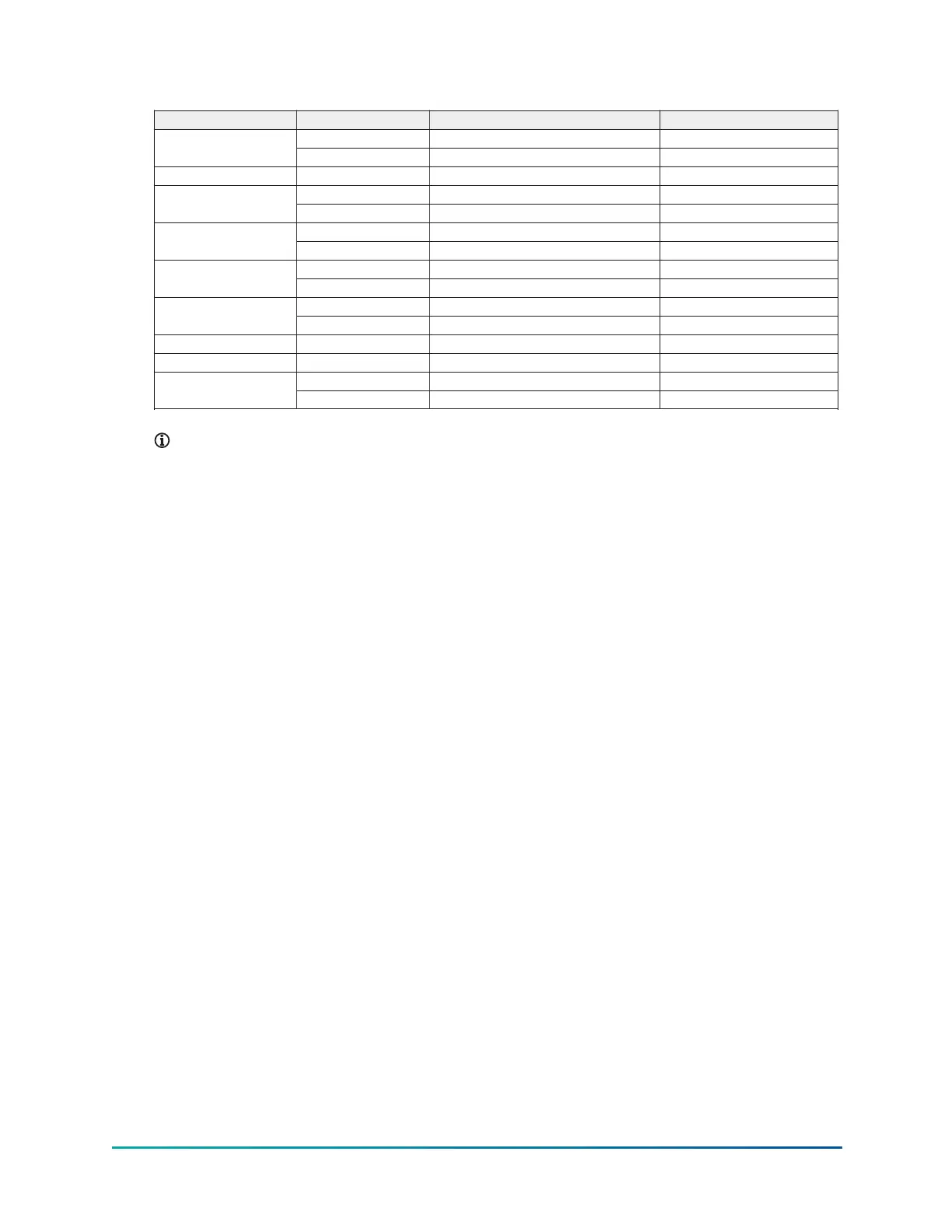

Table 105: Approximate refrigerant and water weight

Evaporator Condenser Refrigerant weight, lb (kg) Water weight, lb

CB2110 540 (250) 980 (450)

EB2510

CB2510 600 (270) 1310 (600)

EB2514 CB2514 840 (380) 1680 (770)

CB2510 640 (290) 1510 (690)

EB2910

CB2910 860 (390) 1760 (800)

CB2514 900 (410) 1940 (880)

EB2914

CB2914 1210 (550) 2240 (1020)

CB2910 920 (420) 2070 (940)

EB3310

CB3310 980 (450) 2580 (1170)

CB2914 1290 (590) 2640 (1200)

EB3314

CB3314 1380 (630) 3310 (1510)

EC3312 CB2912 1331 (605) 2863 (1299)

EC3314 CB3314 1626 (739) 3589 (1628)

CB3314 1908 (867) 4232 (1920)

EC3914

CB3914 2072 (942) 4892 (2220)

Note:

- Refrigerant weight based on maximum tube bundle.

- Water weight is the total water in both shells and for 150 psi, 2-pass, compact

waterboxes.

Condensers and evaporator maintenance

Maintenance of condenser and evaporator shells is important to provide trouble free operation of

the chiller. The water side of the tubes in the shell must be kept clean and free from scale.

The major portion of maintenance on the condenser and evaporator will deal with the maintaining

the water side of the condenser and evaporator in a clean condition.

The use of untreated water in cooling towers, closed water systems, etc. frequently results in one or

more of the following conditions:

• The formation of scale

• The occurrence of corrosion or rusting

• The formation of clime and algae

It is therefore to the benefit of the user to provide for correct water treatment to provide for

a longer and more economical life of the equipment. Use the following recommendation to

determine the condition of the water side of the condenser and evaporator tubes.

• The condenser tubes should be cleaned annually or earlier if conditions warrant. If the

temperature difference between the water off the condenser and the condenser liquid

temperature is more than 4°F (2°C) greater than the difference recorded on a new unit, it is a

good indication that the condenser tubes require cleaning. See Cleaning condenser tubes for

condenser tube cleaning instructions.

• The evaporator tubes under normal circumstances will not require cleaning. If the temperature

difference between the refrigerant and the chilled water increases slowly over the operating

season, it is an indication that any of the following conditions has occurred:

- The evaporator tubes may be fouling

- A water bypass in the waterbox may require gasket replacement

- Refrigerant may have leaked from the chiller

157

YMC

2

Mod B with OptiView Control Center

Loading...

Loading...