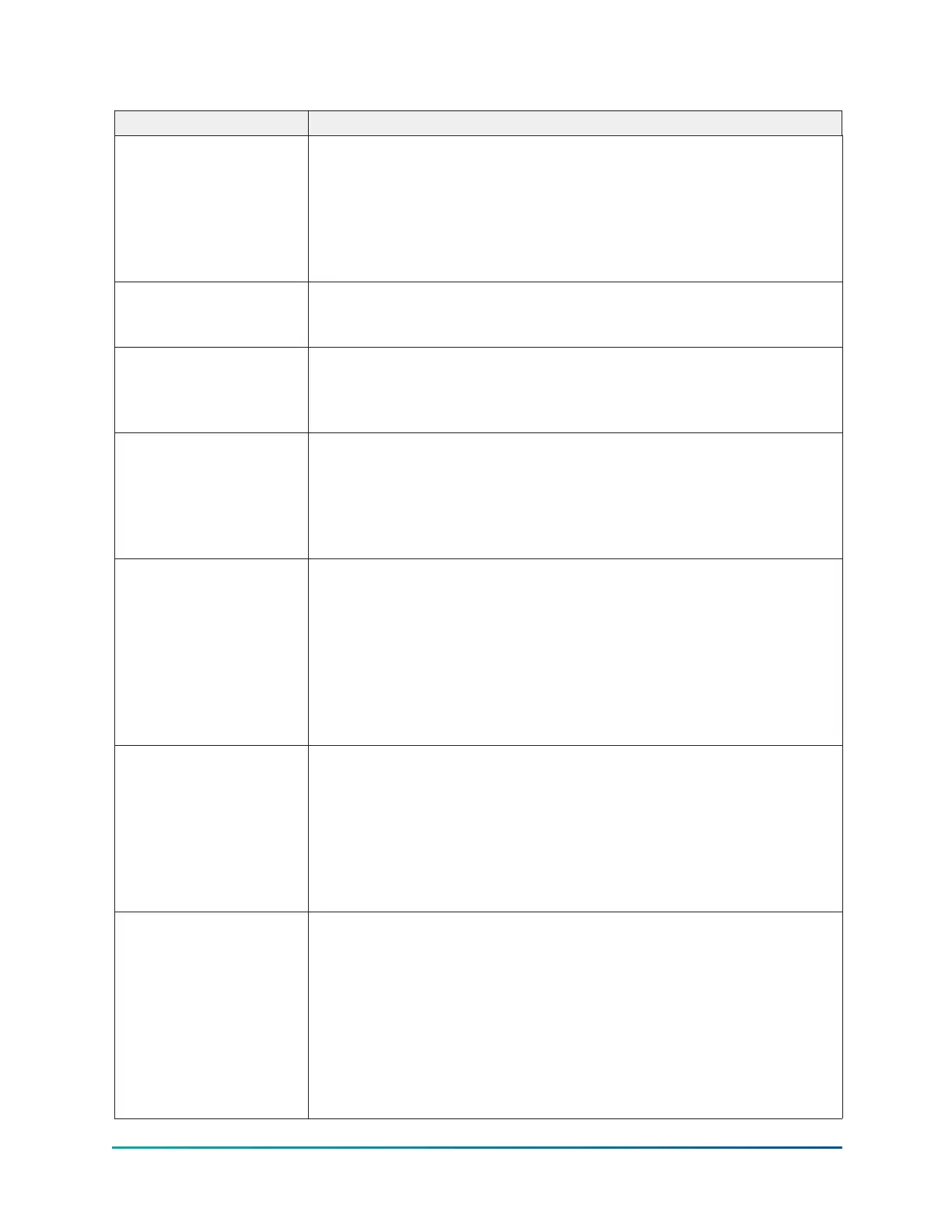

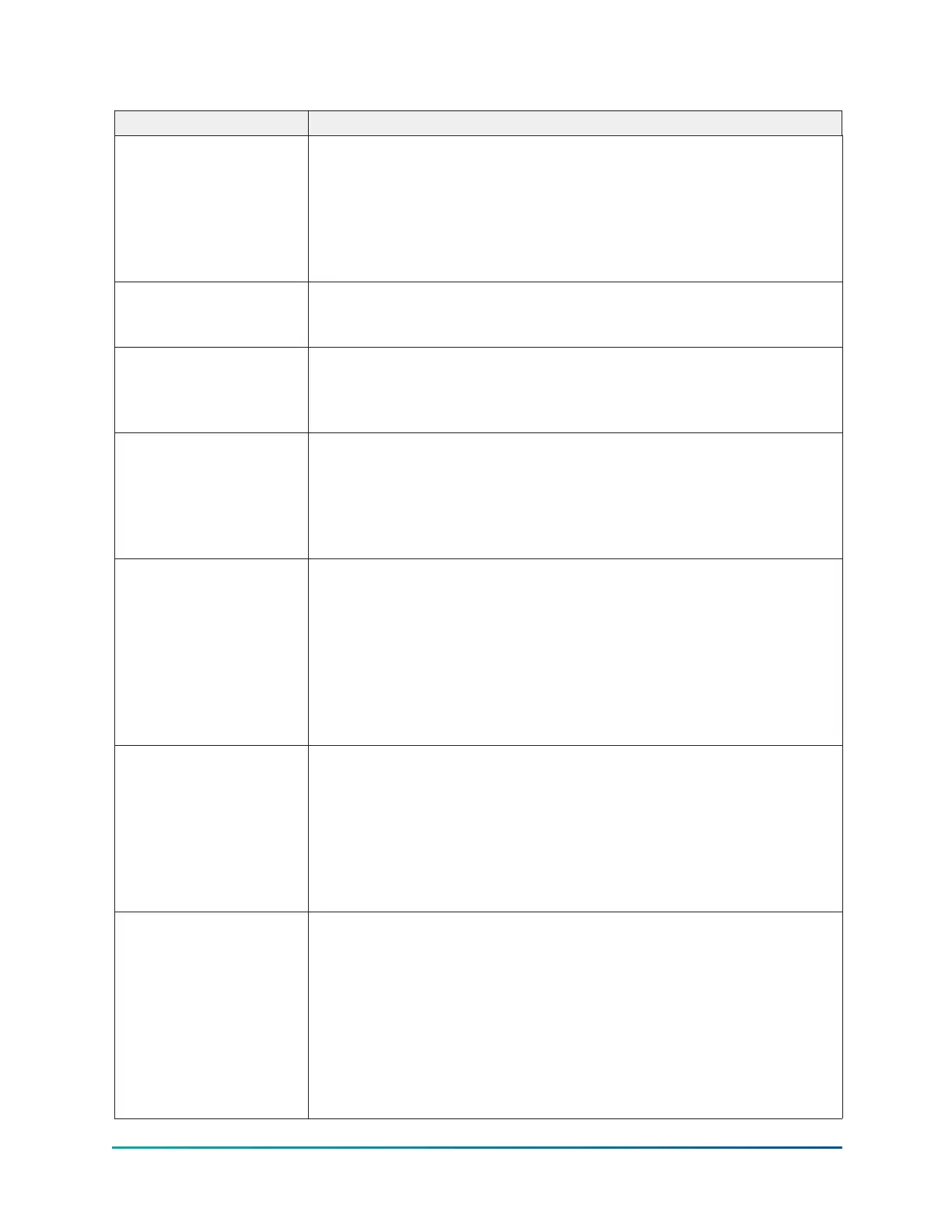

Table 97: Warning messages

Message Description

WARNING – MOTOR –

HIGH CURRENT LIMIT

The chiller motor current is greater than or equal to the Motor

Overload current limit. The Motor Overload current limit is

predetermined from the motor model and Maximum VSD Output

Current. While this condition is in effect, chiller capacity control is in

override to reduce current. Normal LCHLT capacity control operation

is resumed and this message automatically clears when the motor

current decreases below this limit.

WARNING – MOTOR

– HIGH HOUSING

TEMPERATURE

The Motor Housing Temperature is greater than or equal to 167°F

(75°C). This warning is released when Motor Housing Temperature is

less than 158°F (70°C).

WARNING - MOTOR

- HIGH ROTOR

TEMPERATURE

This warning occurs when the estimated rotor temperatures exceeds

230°F (110°C) for 3 continuous seconds. This warning will automatically

clear when all winding temperatures decrease below the warning

threshold

WARNING - MOTOR

– HIGH WINDING

TEMPERATURE

This warning occurs when any of the enabled motor winding

temperatures exceeds 275°F (135°C) for 3 continuous seconds. This

warning will automatically clear when all winding temperatures

decrease below the warning threshold. Also it will not act on any

individual winding temperature sensor that has been disabled with the

TEMPERATURE DISABLED Setpoint on the Motor Details Screen.

WARNING – REAL TIME

CLOCK FAILURE

During the initialization process that occurs when power is applied

to the control center, test data is written to a location in the BRAM

battery backed memory device (IC location U52 on Microboard). This

data is then read from the BRAM and compared to the test data. If the

read data is not the same as that which was written to the device, it

is assumed the BRAM and Real time Clock operation is defective and

this message is displayed. The BRAM should be replaced by a qualified

service technician. This message automatically clears when the BRAM

problem has been solved.

WARNING – SETPOINT

OVERRIDE

A blank BRAM battery-backed memory device (IC location U52 on

Microboard) or a failure of this device was detected during the

initialization process that occurs when power is applied to the control

center. Due to this failure, any or all of the programmed Setpoints

could have been corrupted. Therefore, all Setpoints have been

automatically changed to their Default values. All Setpoints will have to

be programmed to their desired values. This message will clear when

the warning reset key is pressed in operator (or higher) access mode.

WARNING – UPS

– BATTERY NOT

CONNECTED

This is an auto reset warning. The minimum and maximum Battery

Voltage that occurs within each 10 second window is stored. At the

end of each 10 second window, if the difference between the min and

max battery voltage is greater than 0.5 V, a counter is increased. If the

difference between them is less than 0.5 V, the counter is reset to 0.

This warning is set when the Battery Disconnected Counter >= 4 (The

intent is for 4 consecutive 10 second windows to see battery voltage

fluctuations to set this fault)

It is released when the Battery Disconnected Counter is 0 for 60

continuous seconds.

YMC

2

Mod B with OptiView Control Center

100

Loading...

Loading...