ATF Instruction Manual

19

7) Inspecting the cramp pressure

Check to see if the lock release lever clicks (in the same manner those of other

feeders click) when you attach the tape feeder onto the feeder bank and close the

lock release lever.

If the lock release lever does not click, make the following adjustments.

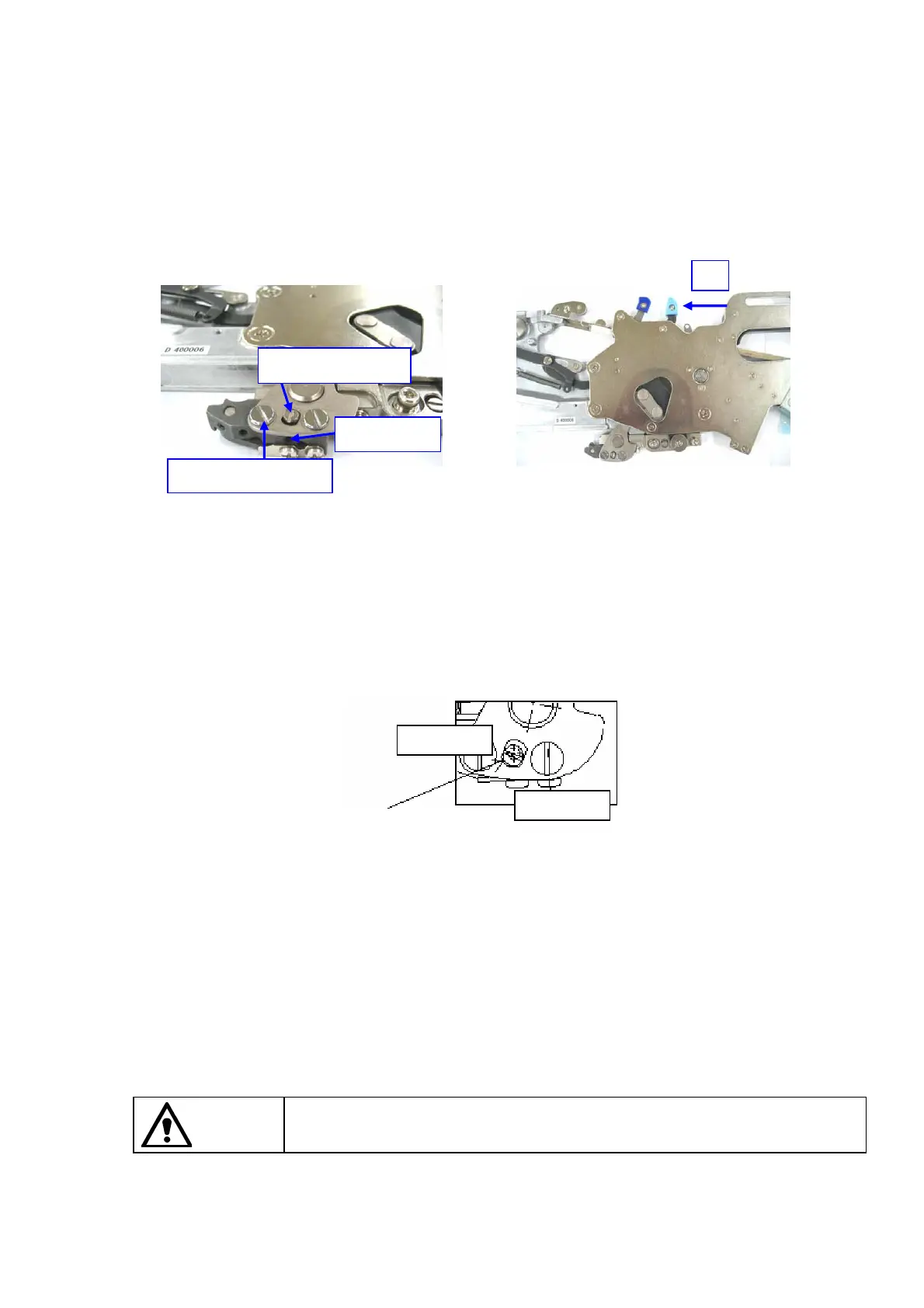

P

Eccentric axis C

Setscrews A (two)

Setscrew B

1) Loosen the setscrews A (two) and setscrew B.

2) Rotate the eccentric axis C and adjust the load “P” imposed when you close the

lock release lever with the tension gauge so that the load can be 12 to 17 N.

3) Tighten the setscrew B, and tighten up the setscrews A with 1.9 to 2.3 N·m.

4) After tightening up the setscrews A and B, repeat operating the cramp several

times to check that the load “P” is 12 to 17 N.

Note: Assemble the eccentric axis C downwards.

Weake

Stron

e

Assembling direction: downwards

8) Inspecting the pick-up position

To maintain the component pick-up accuracy, regularly check and adjust the

pick-up position.

If you happen to give a shock to or impose unbearable load on the tape feeder,

check the pick-up position also.

If the pick-up position is shifted from the regulated one, it may increase the number

of pick-up errors or increase the cycle time due to unavailability of a simultaneous

pick-up of two or more components.

CAUTION

To adjust the pick-up position, the dedicated feeder inspection jig is required.

For the inspection jig, refer to its Instruction Operations of the inspection jig.

Loading...

Loading...