−53 −

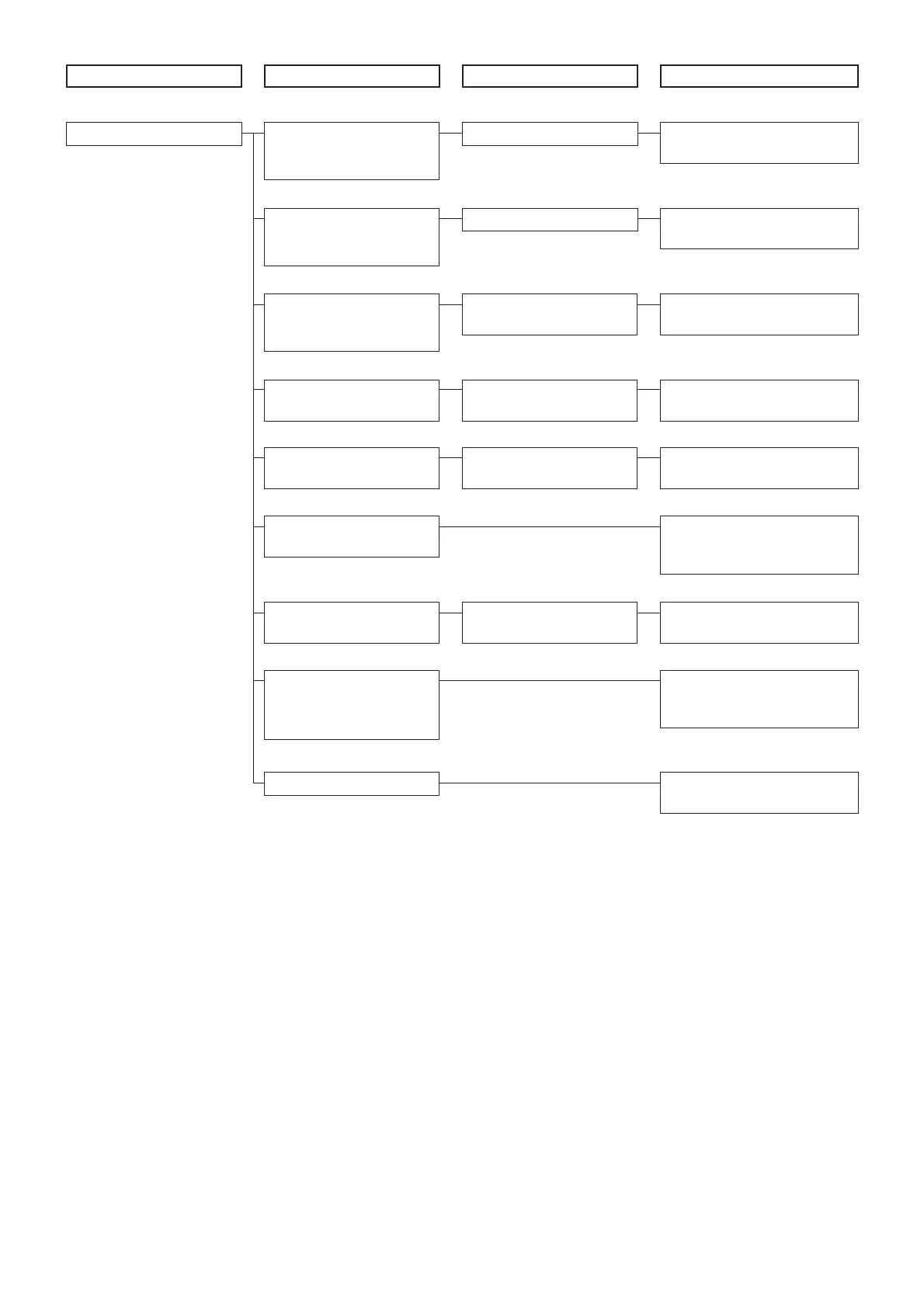

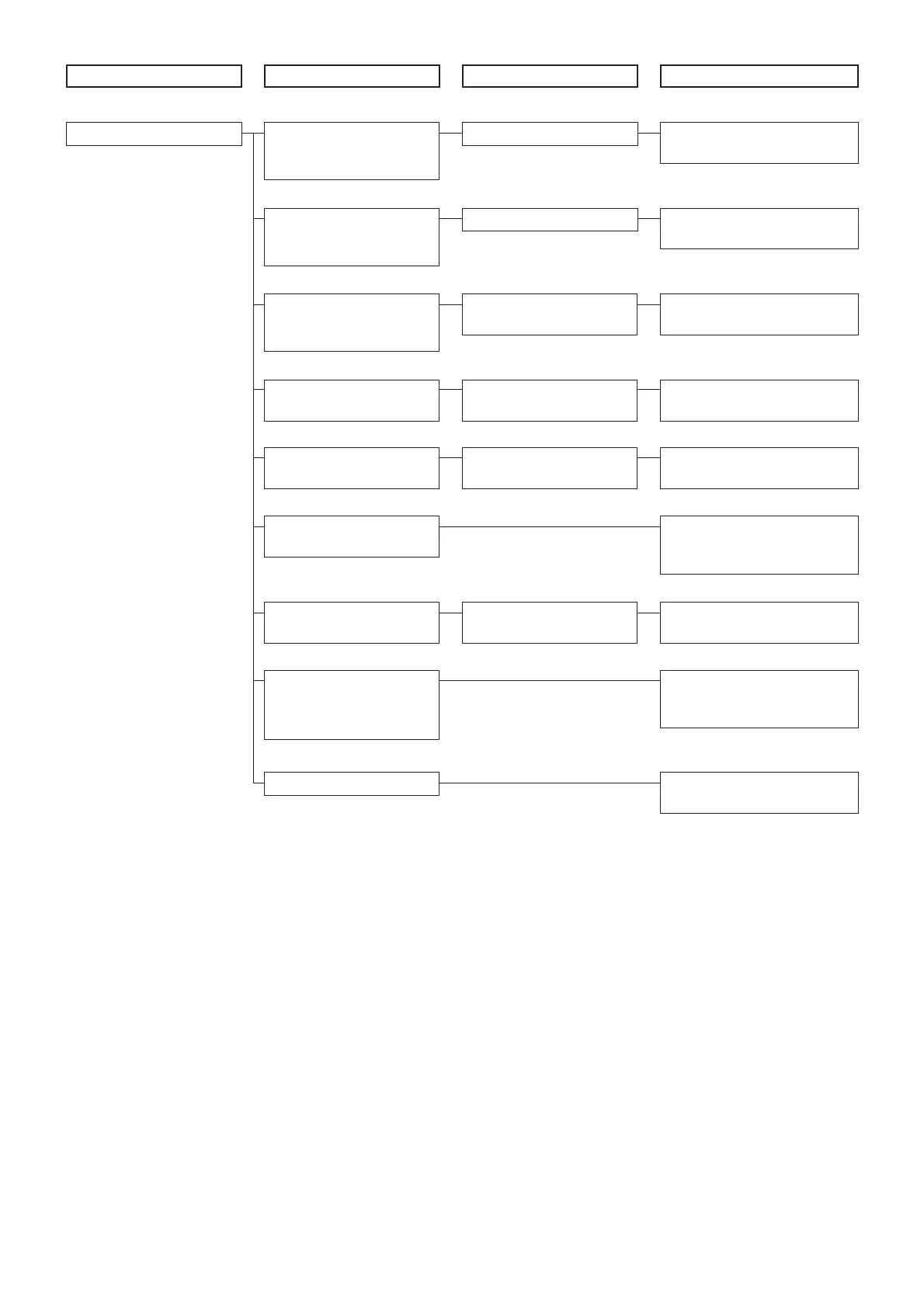

Troubles Causes Checking Corrective measures

2. Stitch skipping Clearance between the

needle and the blade point

of hook is too large.

Needle-to-hook timing is

excessively advanced or

retarded.

Presser foot is rising.

(Pressure of the presser

foot is too low.)

Height of the needle bar is

improper.

Blade point of the hook is

blunt.

Improper type of needle is

used.

Hook needle guard is not

functioned.

Thread take-up spring

works excessively or the

stroke of the spring is too

small.

Feed timing is not proper.

Check the clearance.

Check the specified dimension.

Check the pressure of the

presser foot.

Check the lowest point of

the needle bar.

Check the blade point of the

hook.

Check the functional

amount of the needle guard.

Refer to “Needle-to-hook

timing” on page 9.

Refer to “Needle-to-hook

timing” on page 9.

Tighten the presser spring

regulator.

Refer to “Needle-to-hook

timing” on page 9.

Correct the blade point or

replace the hook.

Replace the needle with one

which is thicker than the current

needle by one count.

Refer to “Needle-to-hook

timing” on page 9.

Decrease the tension of the

spring and increase the stroke

of the spring.

Refer to “Main shaft-to-hook

driving shaft timing” on page 11.

Loading...

Loading...