805.19

K-Commander Loss-in-Weight Programming

Rev: G Produced by the K-Tron Institute

LWF Page 01: Feed Factor Setup, Continued

Page 01

variable list

con't

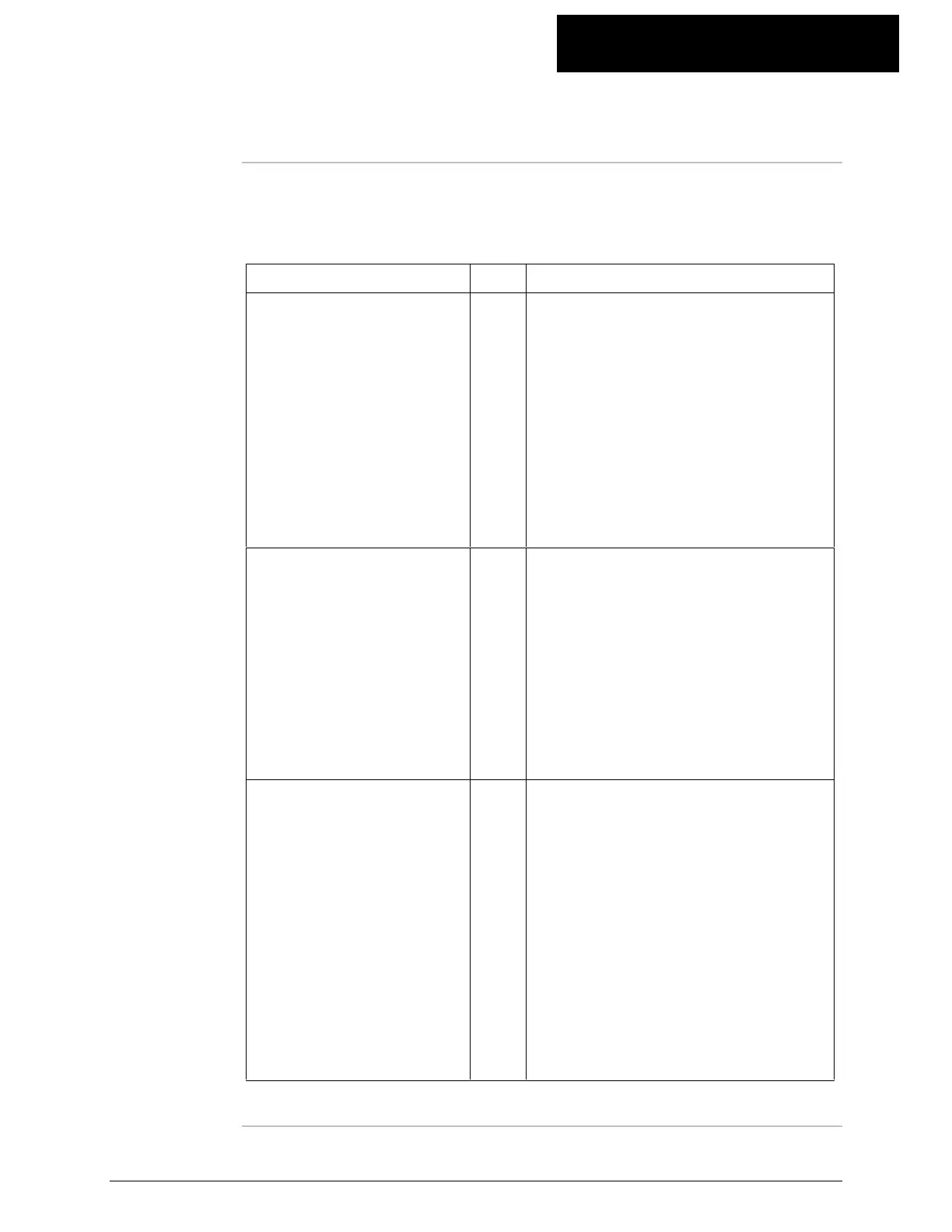

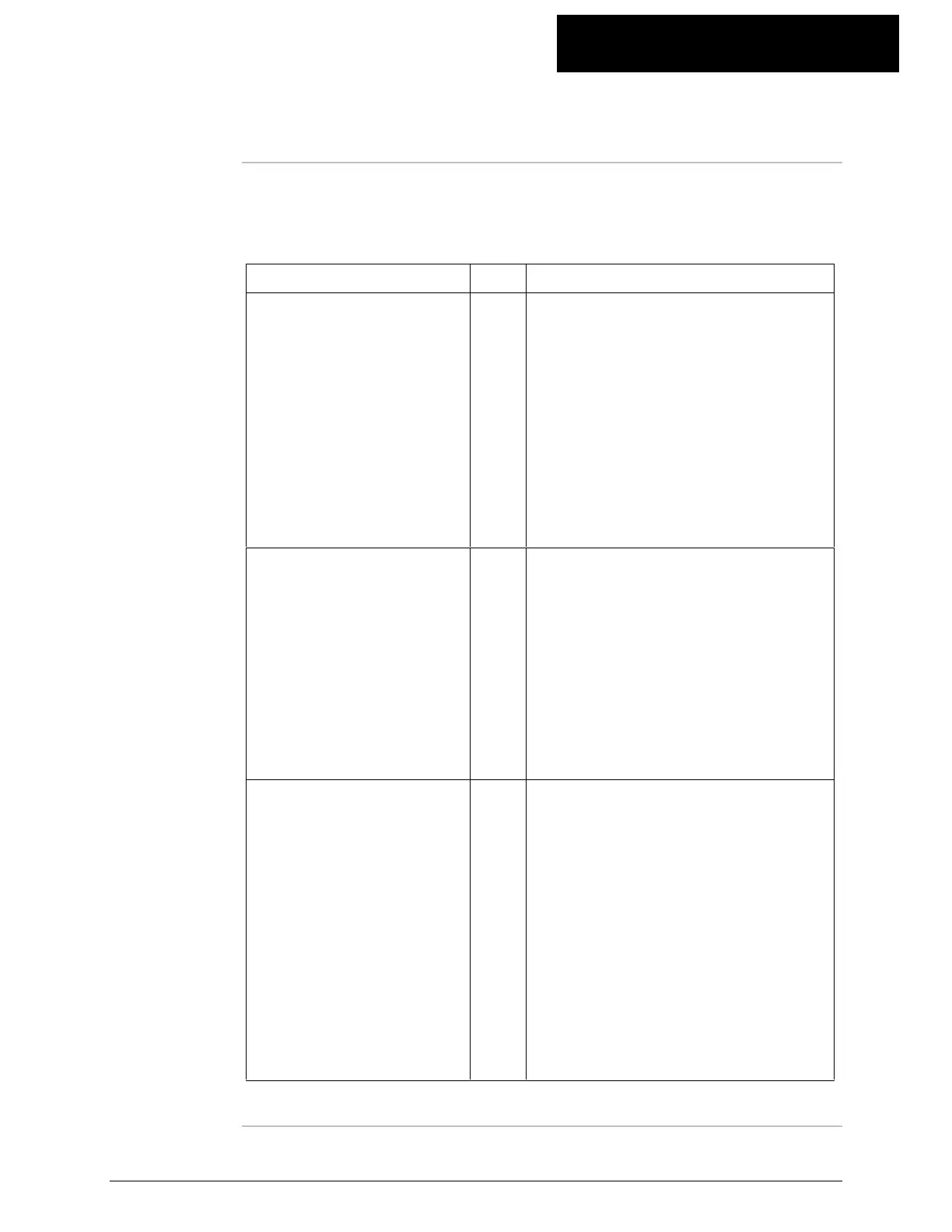

Variable Name Edit? Description

Calib. Correlation Limit A slow running average of the

correlation from past runs taken

during feedfactor calibration based

upon a linear regression of the

sample data computed during the

calibration time. An alarm is

generated and the Initial Feedfactor

is set to zero if the new correlation

is below this number. To correct,

enter a longer calibrate time then

increase the calibrate drive cmd.

Last Calib. Correlation The correlation value captured

during the last feedfactor

calibration. Look for consistency. A

value of 100 is perfect, 90 is good

indicating consistent material flow,

80 is indicating the flow is less

consistent. The smaller the number,

the less consistent the flow,

possibly suggesting changing the

feeder type or feed screw if used.

Material Fed Last

Calibration

The physical amount of product

delivered during the calibration

cycle. Divide this value by the

Calibrate Time to compute the

massflow rate. If you reset the

totalizer before starting, the

totalizer will give you the same

value. Compare this value to the

actual material weight delivered

during the calibrate cycle. If the

actual weight agrees with the value

displayed here, the feeder is also

calibrated accurately by weight.

Continued on next page

Loading...

Loading...