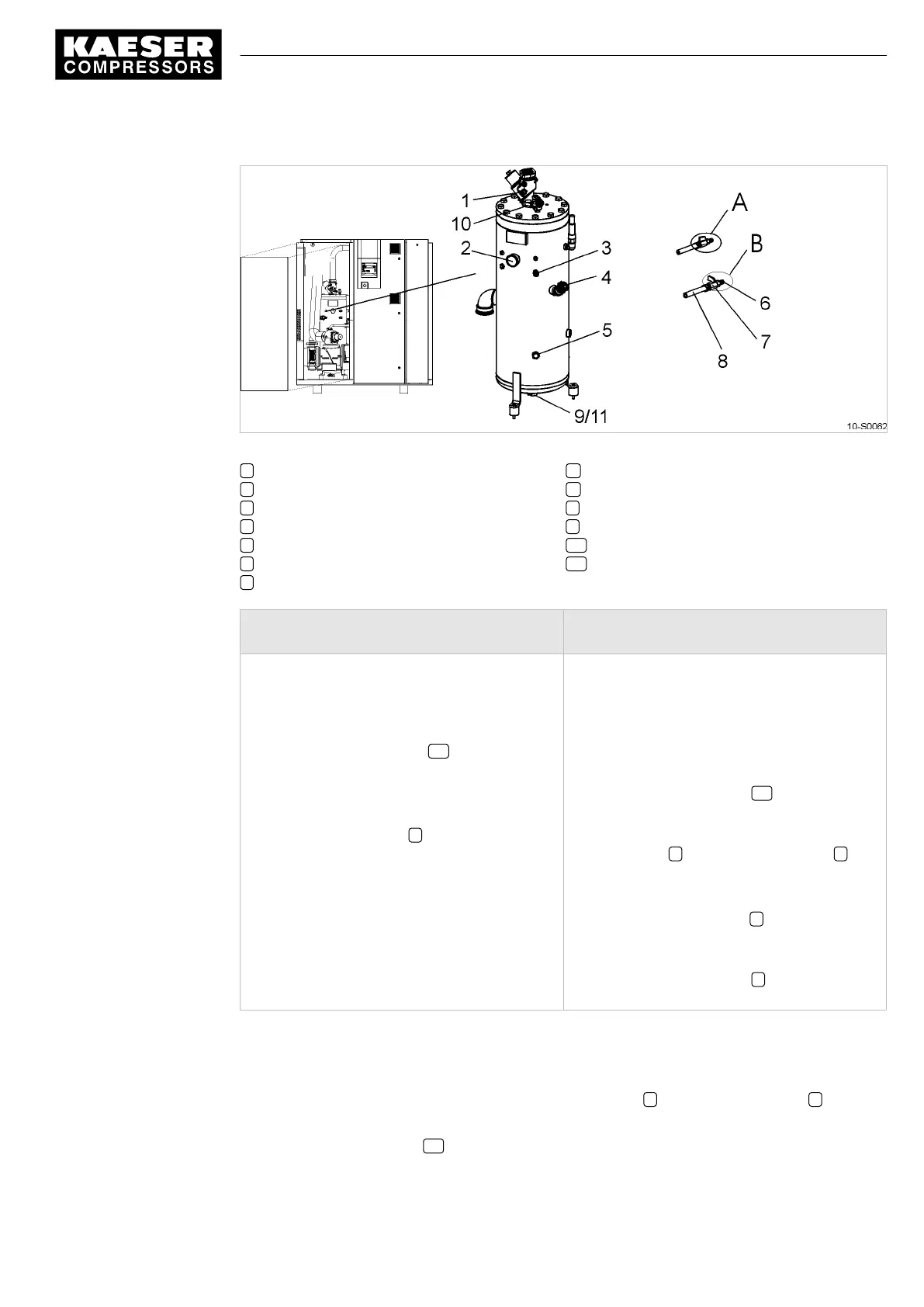

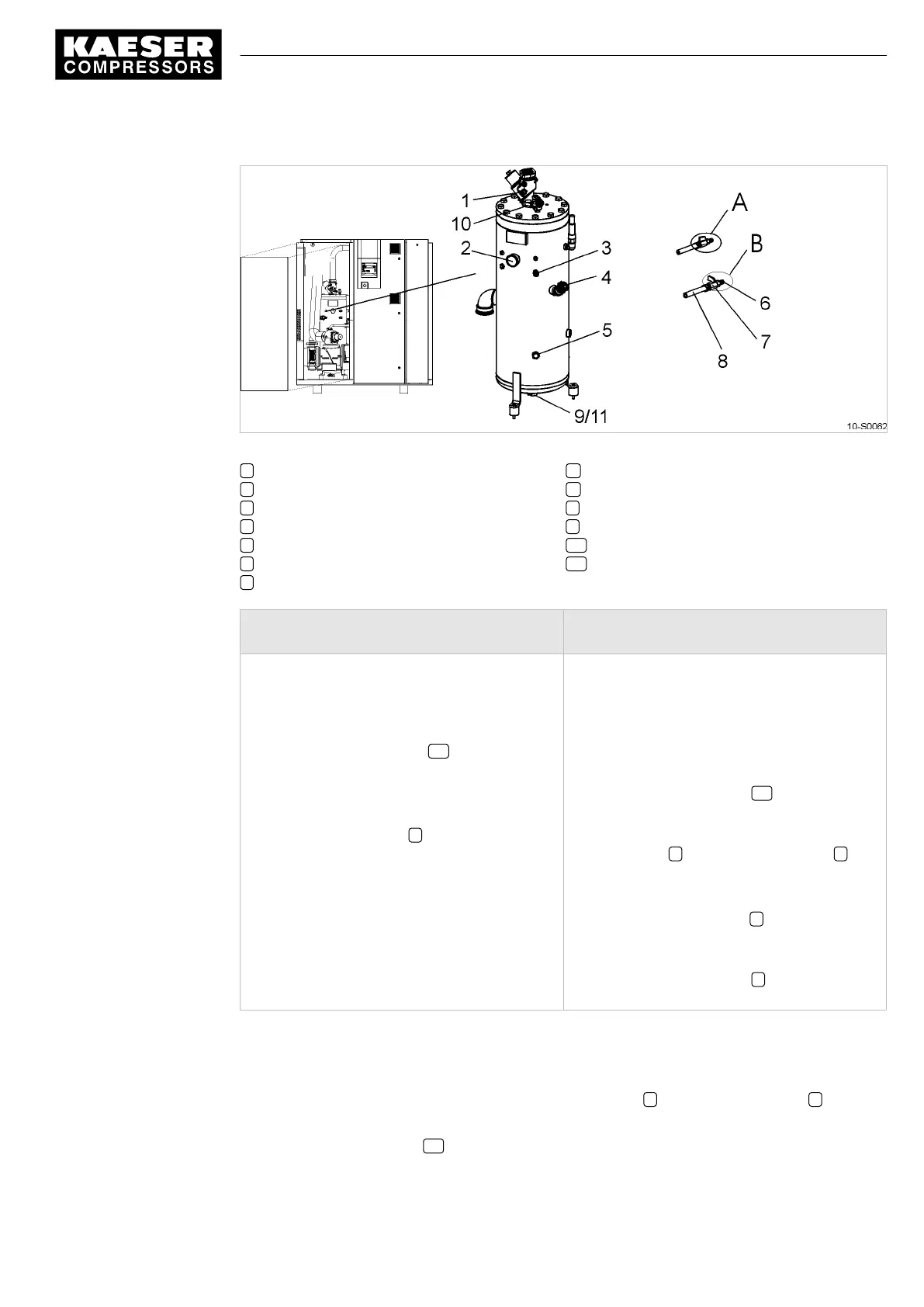

Fig. 32 Changing the cooling oil, oil separator tank

1 Hose coupling (air cooler venting)

2 Pressure gauge

3 Hose coupling (oil separator tank venting)

4 Oil filler port with plug

5 Cooling oil level indicator

6 Male hose fitting

7 Shut-off valve

A Shut-off valve open

B Shut-off valve closed

8 Maintenance hose

9 Hose coupling (oil drain)

10 Shut-off valve (venting line)

11 Shut-off valve (oil drain)

Changing the oil with internal pressure Changing the oil using an external compressed

air source

Machine has been running at least 5 minutes un‐

der LOAD.

The machine is fully vented, the pressure gauge

on the oil separator tank reads 0 bar.

1. Close the shut-off valve 10 in the venting

line.

2. Select IDLE running.

3. Start the machine and watch the oil separator

tank pressure gauge 2 until it reads 43–73

psig.

4. Switch off and lock out the power supply dis‐

connecting device and check that no voltage

is present.

5. Wait at least 2 minutes to allow the oil to flow

back to the separator tank.

The power supply isolating device is switched off,

the device is locked off,

a check has been made that no voltage is present.

The machine is fully vented, the pressure gauge

on the oil separator tank reads 0 psig.

An external source of compressed air is available.

1. Close the shut-off valve 10 in the venting

line.

2. With the shut-off valve closed, insert the male

hose fitting 6 into the hose coupling 3 .

3. Connect the maintenance hose to the exter‐

nal air supply.

4. Open the shut-off valve 7 until the pressure

gauge on the oil separator tank reads 43–

73 psig.

5. Close the shut-off valve 7 and remove the

male hose fitting from the coupling.

Draining the oil from the separator tank

1. Have an oil receptacle ready.

2. With the shut-off valve closed, insert the male hose fitting 6 into the hose coupling 9 .

3. Place the other end of the maintenance hose in the oil receptacle and secure it in place.

4. Open the shut-off valve 11 .

10 Maintenance

10.16 Changing the cooling oil

9_5708 08 USE

Service Manual Screw Compressor

BSD

79

Loading...

Loading...