11Kmsrup A/S • 5512850_D1_GB_01.2016

MULTICAL® 402

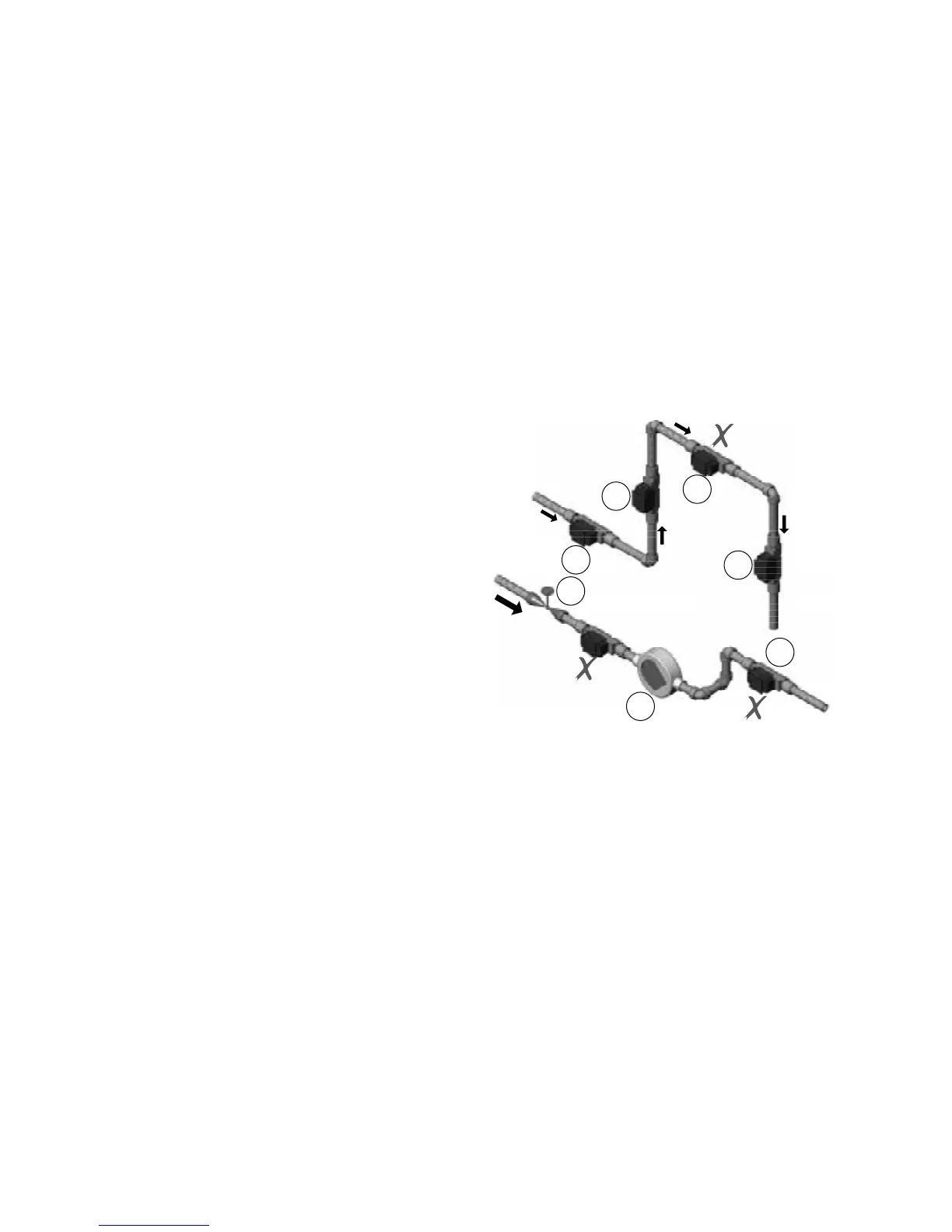

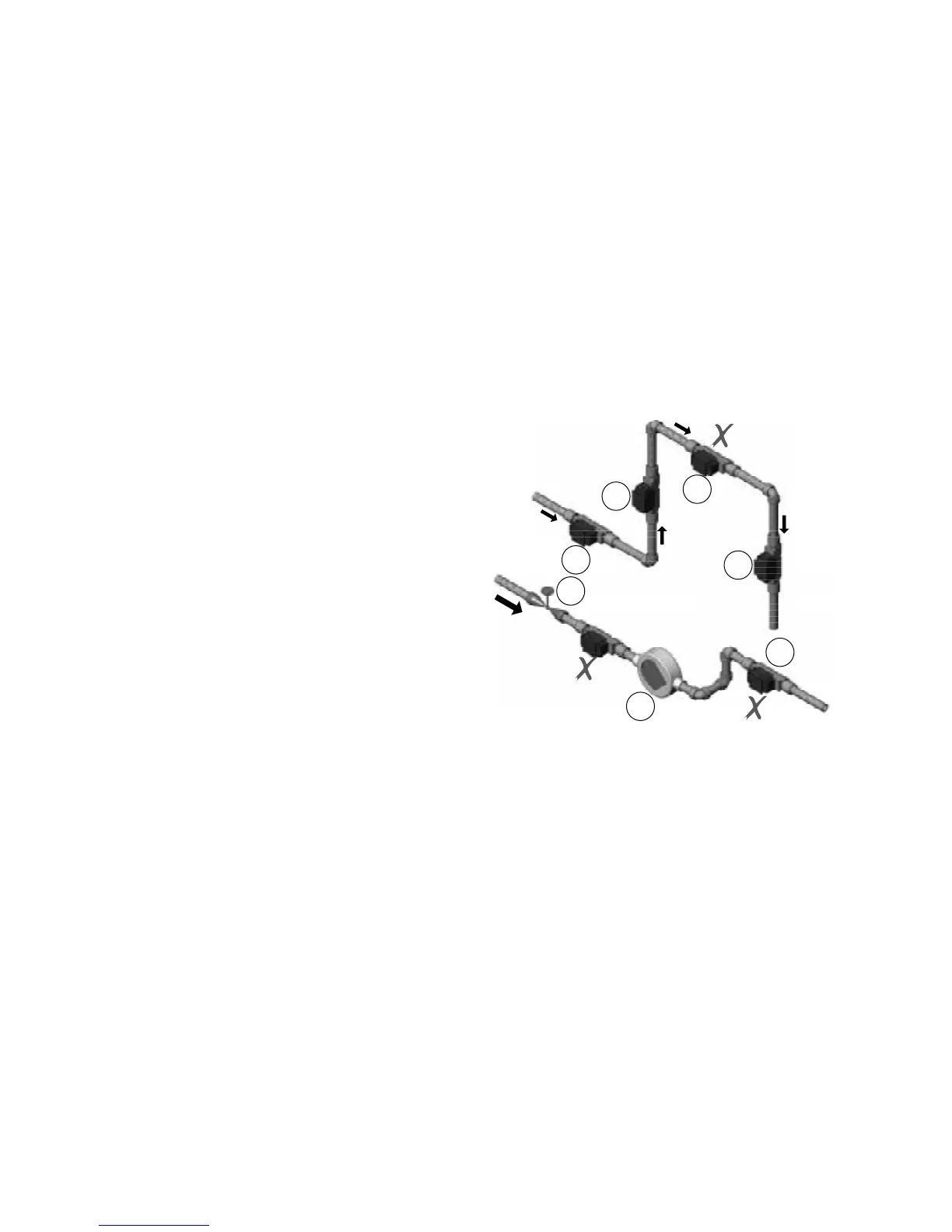

Glnds nd gskes re mouned s shown in he bove drwing.

Srigh inle: MULTICAL® 402 requires neiher srigh inle nor srigh

oule o mee he Mesuring Insrumens Direcive (MID) 2014/32/EU, OIML

R75:2002 nd EN 1434:2007.

A srigh inle secion will only be necessry in cse of hevy flow

disurbnces before he meer. We recommend you o follow he guidelines

described in CEN CR 13582.

For sysems h lck emperure inermixure nd sysems wih em-

perure srificion respecively we recommend srigh inle of

10 x DN.

A Recommended flow sensor

posiion

B Recommended flow sensor

posiion

C Unccepble posiion due o

risk of ir build-up

D Accepble in closed sysems.

Unccepble posiion in open

sysems due o risk of ir build-

up in he sysem

E A flow sensor ough no o be

plced immediely fer

vlve, wih he excepion of

block vlves (bll vlve ype)

which mus be fully open when

no used for blocking.

F A flow sensor mus never be

plced on he inle side of

pump

G A flow sensor ough no o be

plced fer double bend in

wo levels.

E

F

G

A

B

C

D

In order o preven cviion he opering pressure

MULTICAL® 402 mus be min. 1.5 br q

p

nd min. 2.5 br q

s

. This pplies

o emperures up o pprox. 80 °C.

MULTICAL® 402 mus no be exposed o pressure below he mbien

pressure (vcuum).

Loading...

Loading...