EN

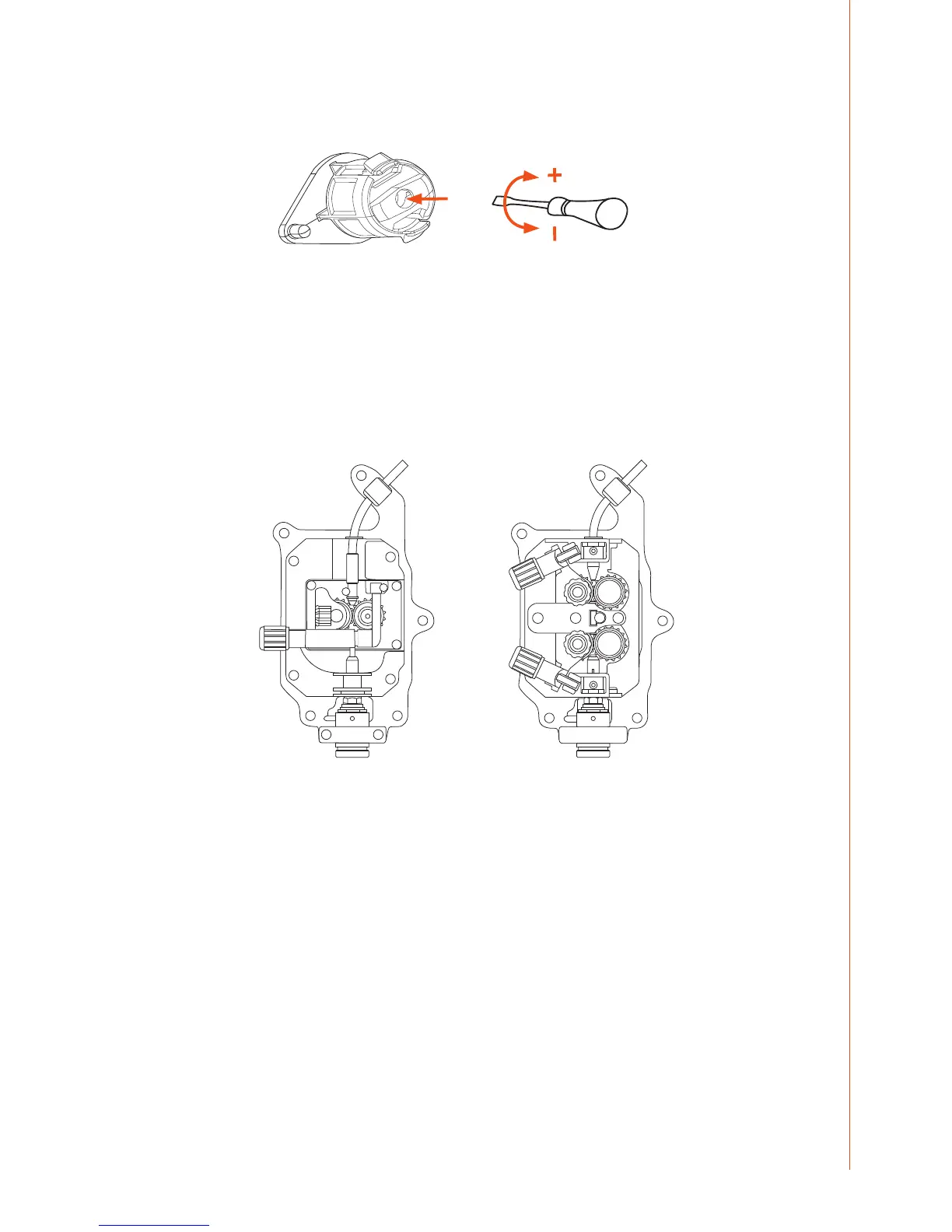

4.3 Setting the spool brake force

To prevent the ller wire from uncoiling on overrun following use at high feed speeds, you can

change the brake force of the welding spool. Adjust the spool brake force through the hole in

the spool locking mechanism. Increase the force by turning the screw clockwise and decrease

it by turning it anticlockwise.

NOTE! Do not over tighten and reduce the pressure for light ller wire types.

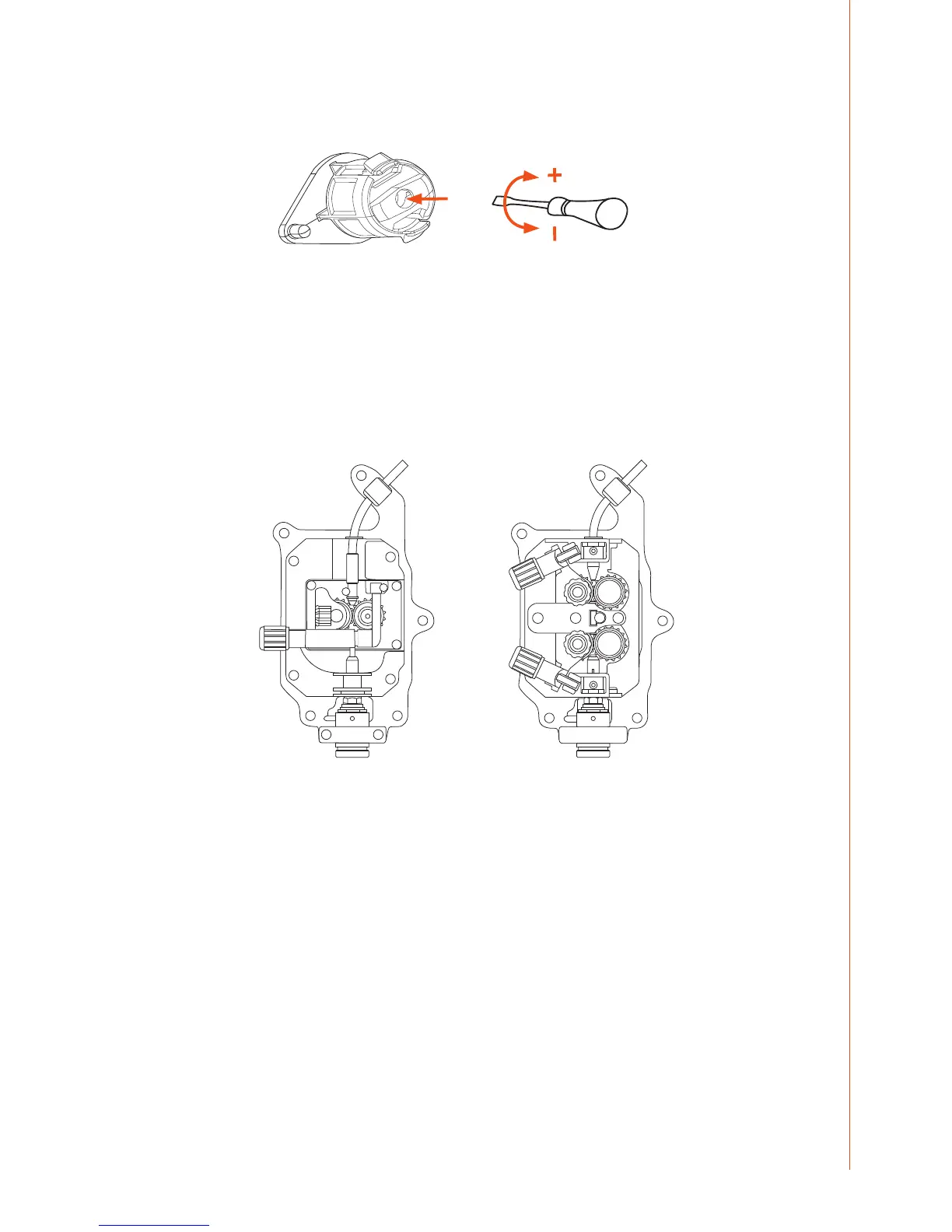

4.4 Loading the welding wire to feed mechanism

GT02 DuraTorque

NOTE! Always ensure that ALL wire guide tubes are correctly selected and installed before

connecting the welding gun.

1. Release the pressure lever(s) and open the pressure arm(s) carrying the top wire feed roll,

lifting clear on its pivot.

2. Draw some loose ller wire from the spool and carefully push it through the liner and

bronze guide at the back of the wire feed mechanism. Push the ller wire over the feed

roll groove and through the wire guide(s) tubes and Euro connector block, exposing

about 150 mm of ller wire from the front of the machine.

3. Close the top feed roll(s) lever(s) over the ller wire and close the pressure arm(s).

11

© Kemppi Oy / 1135

Loading...

Loading...