EN

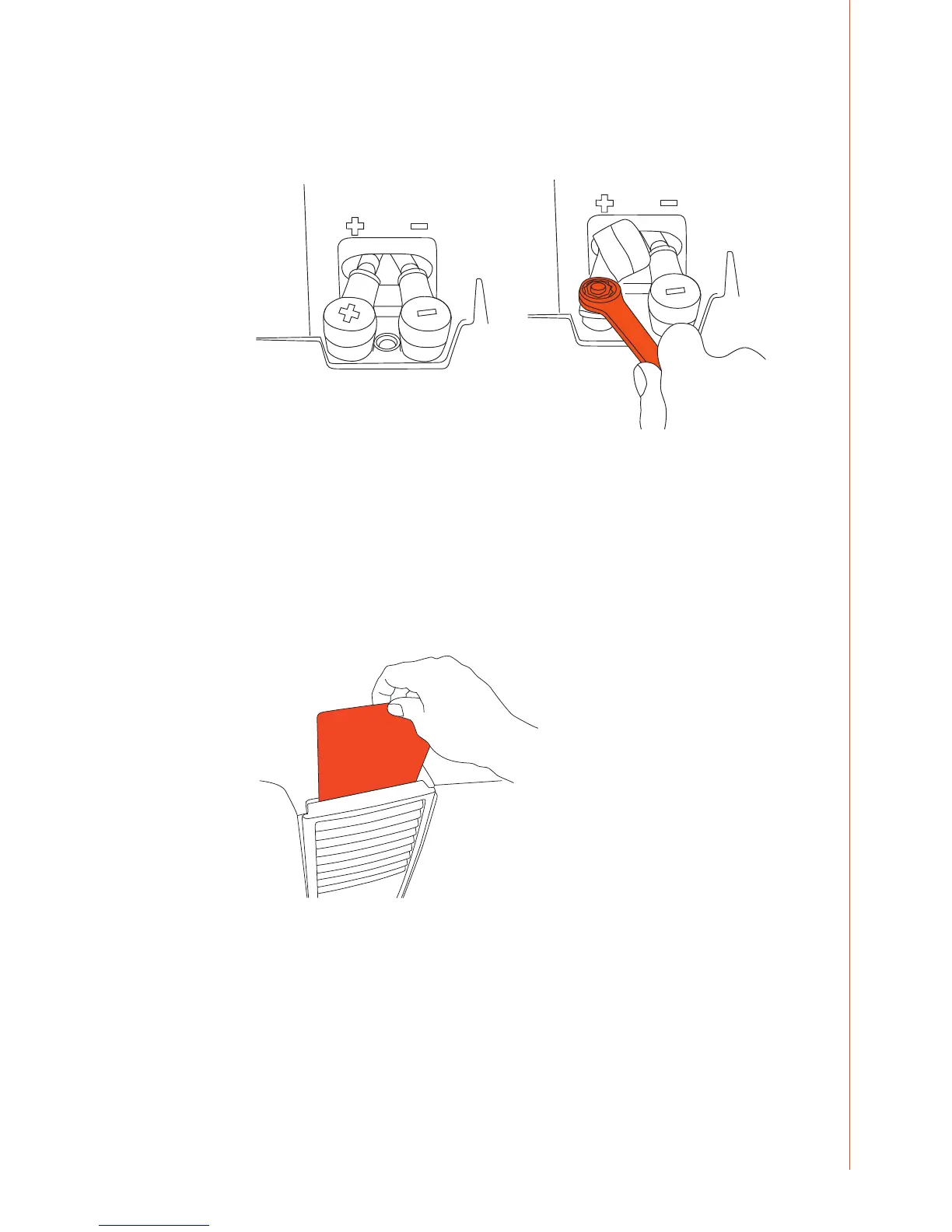

4.9 Reversing polarity

Some ller wires are recommended to be welded with the gun in the minus pole (–), so the

polarity should be reversed. Check the recommended polarity from the ller wire package.

1. Disconnect the machine from the mains.

2. Expose the terminal connections by bending the protective rubber covers away from the

terminal.

3. Remove the terminal tightening nuts and washers. Note the correct order of the

washers!

4. Interchange the cables.

5. Install the washers in place and re-tightening the securing nuts.

6. Replace the rubber terminal covers. The rubber covers must always protect the terminals

during use.

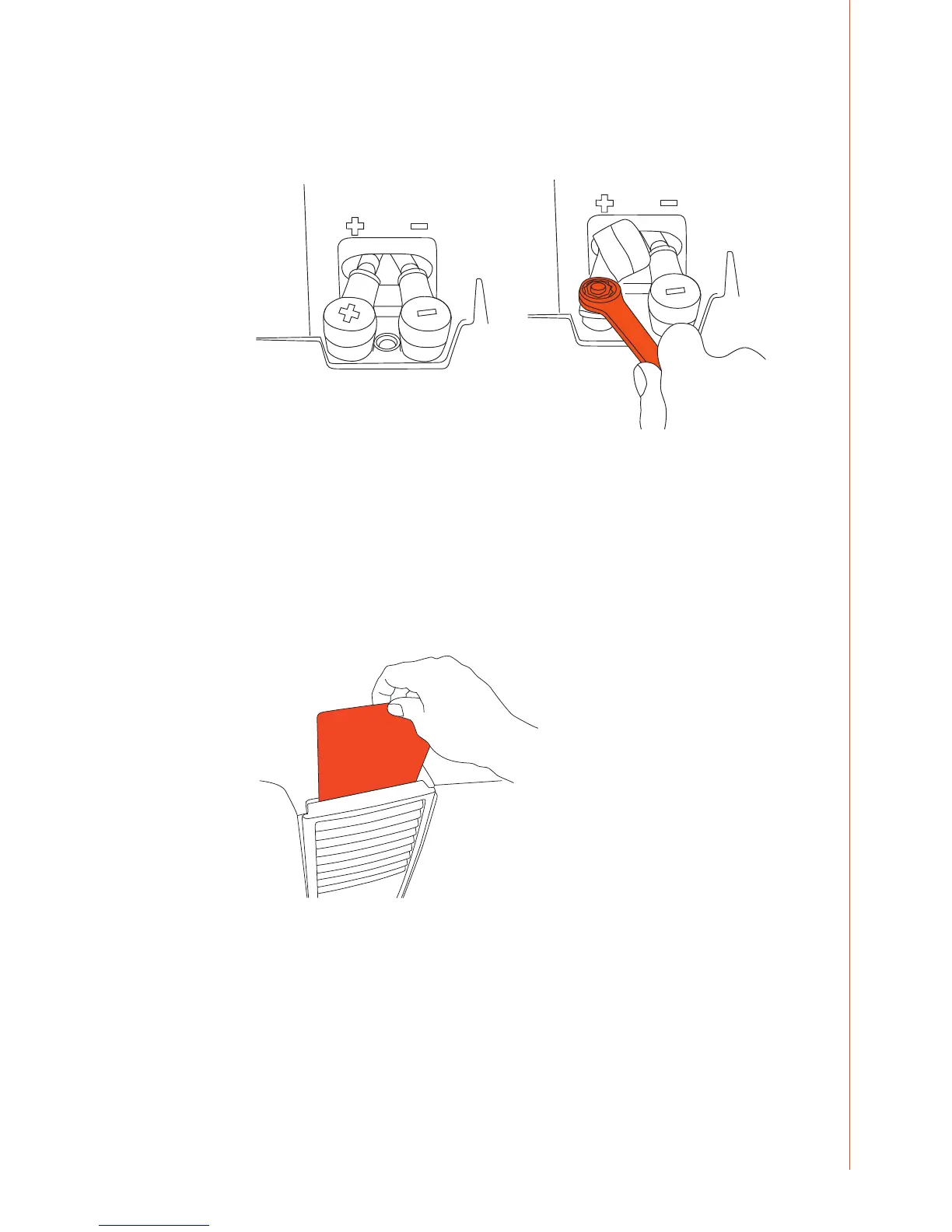

4.9.1 Dusty work environments

If the working environment frequently carries airborne metallic dust particles due to

fabrication practices, it is recommended that you install a lter casette to the machine.

Particle lter cassette's ordering code: W005852.

Fitting the particle lter cassette provides additional protection to your welding machine and

lengthens its service intervals.

Filter maintenance

Once tted, the lter should be removed, checked and cleaned with dry compressed air

weekly. Every six months, wash the lter in a solution of warm soapy water. Allow to dry

thoroughly before replacing.

17

© Kemppi Oy / 1135

Loading...

Loading...