EN

5. USING CONTROL PANELS

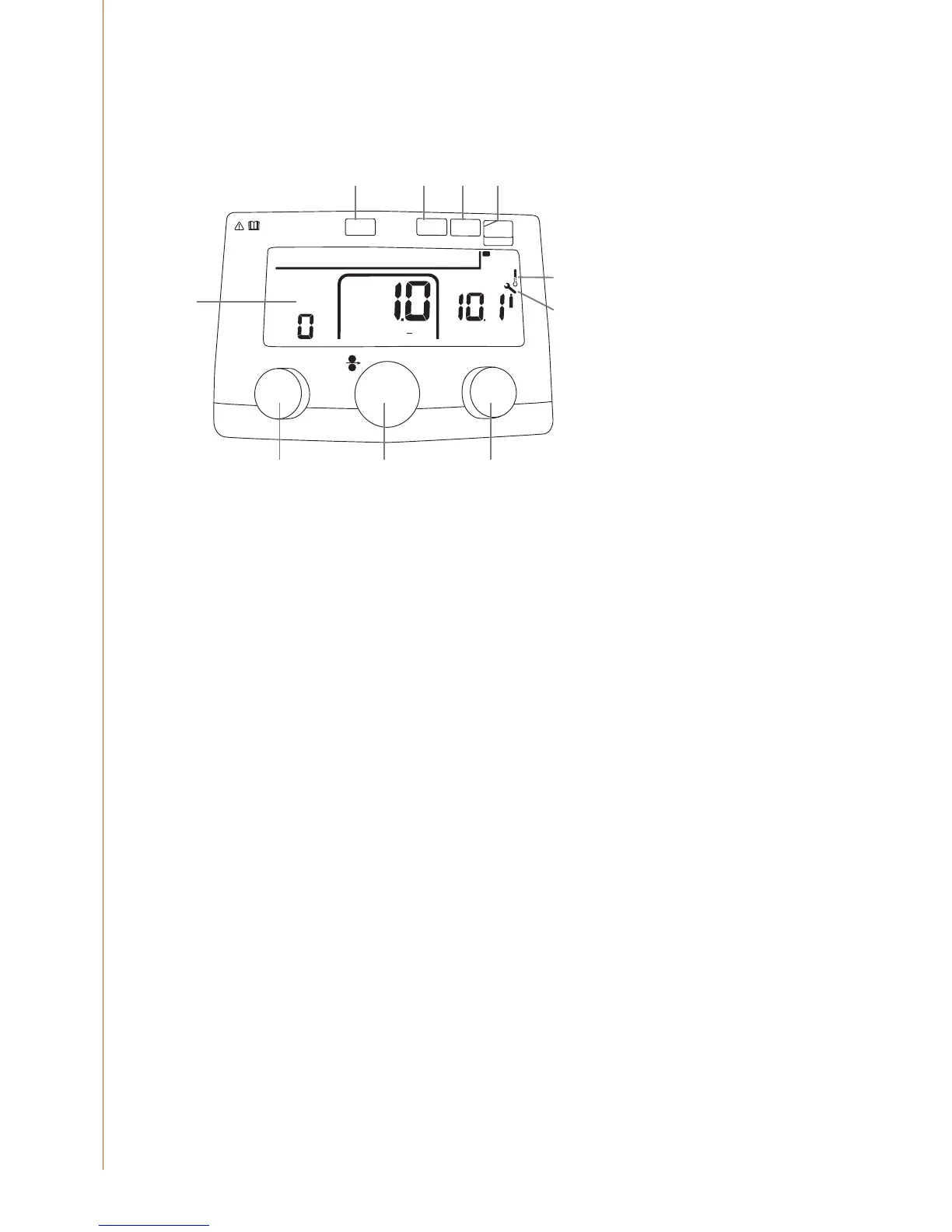

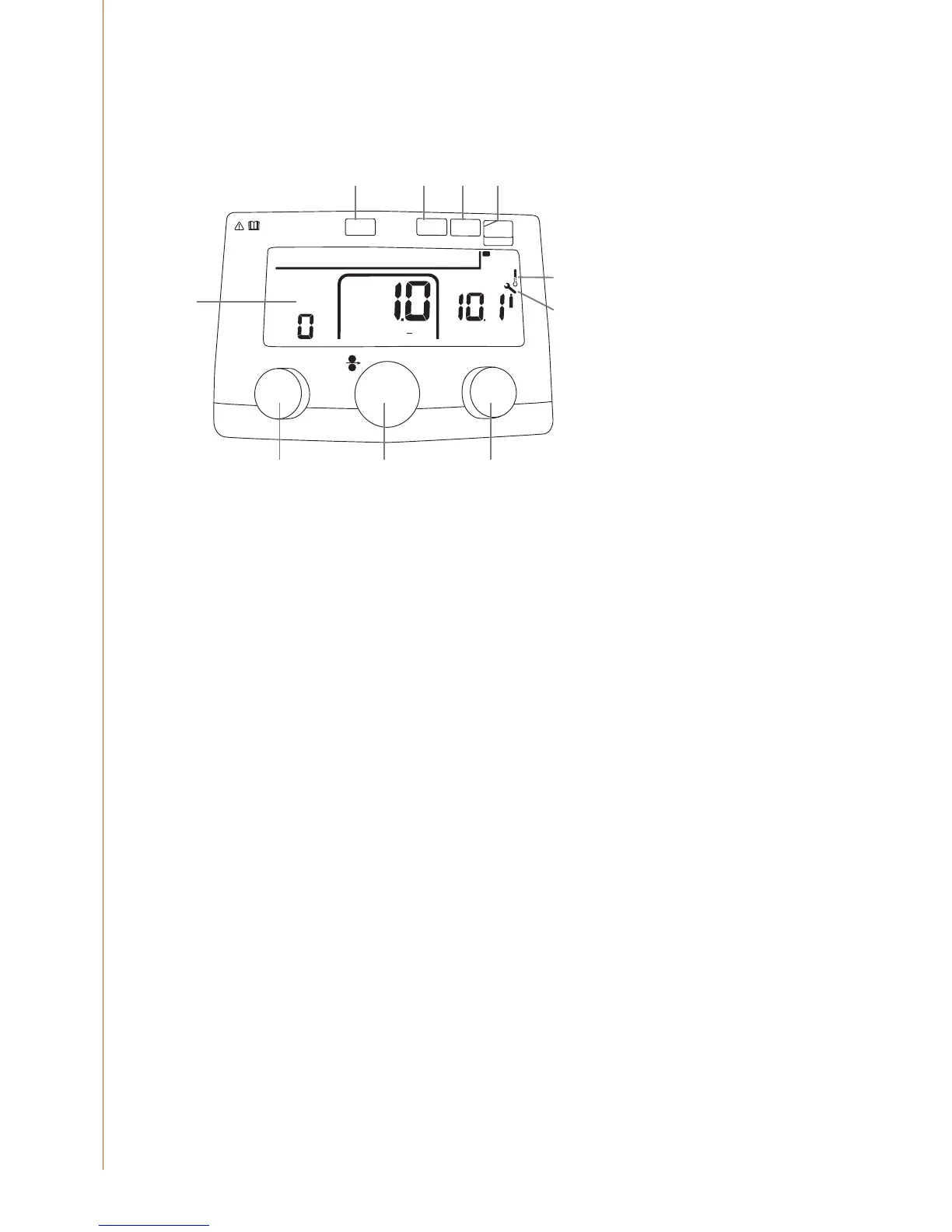

5.1 Regular control panel

DYNAMICS

U

W006169

2T / 4TGAS

MIG

HOT SPOT

SPOT /

CYCLE

POST GAS

m

min

MANUAL

4T

V

1. 2. 3.

4. 5. 6. 7.

8.

9.

10.

Models featuring the regular (R) control panel oer the following control functions and

features.

1. Control knob for welding dynamics

2. Control knob for wire feed speed

3. Control knob for welding voltage

4. Shielding gas button

5. Timer button for spot welding and cycle arc welding

6. 2T/4T gun switch latching button

7. Selection for MIG/MAG or HOT SPOT function

8. Parameter display

9. Overheating indicator

10. WireLine service indicator

1. Control knob for welding dynamics

Dynamics function controls the rate of rise of current when the ller wire is in short circuit

with the welding plate. This control adjustment is necessary due to the alternative welding

parameters, materials, wire sizes, gas types and current values used.

The welding dynamics scale is –9 to +9. Negative values make the rise of current slower, which

results in a hotter and more uid weld characteristic. Positive values make the rise of current

faster, which results in a colder welding condition. This can result in more spatter during

welding depending on the ller wire size and type used.

How to nd the optimal dynamics setting?

Start by setting ‘0’ and make a test weld after selecting the correct wire feed speed and

voltage values. Fine tune the welding arc by trying dierent values in the negative (-) and

positive (+) sides of the dynamics scale.

2. Control knob for wire feed speed

This control knob increases and reduces the speed of ller wire delivery to the welding arc.

The scale is regulated in meters per minute. There is also a graphical display bar indicating the

proportion of motor speed selected.

Kempact 251R, 253R, 323R, 181A, 251A, 253A, 323A

18

Loading...

Loading...