EN

3.8 SHIELDING GAS

As MIG shielding gas is used carbon dioxide, mixed gases and argon. Shielding gas ow rate is

dened by welding current size. Typical rate of gas in welding of steel is 8-15 l / min.

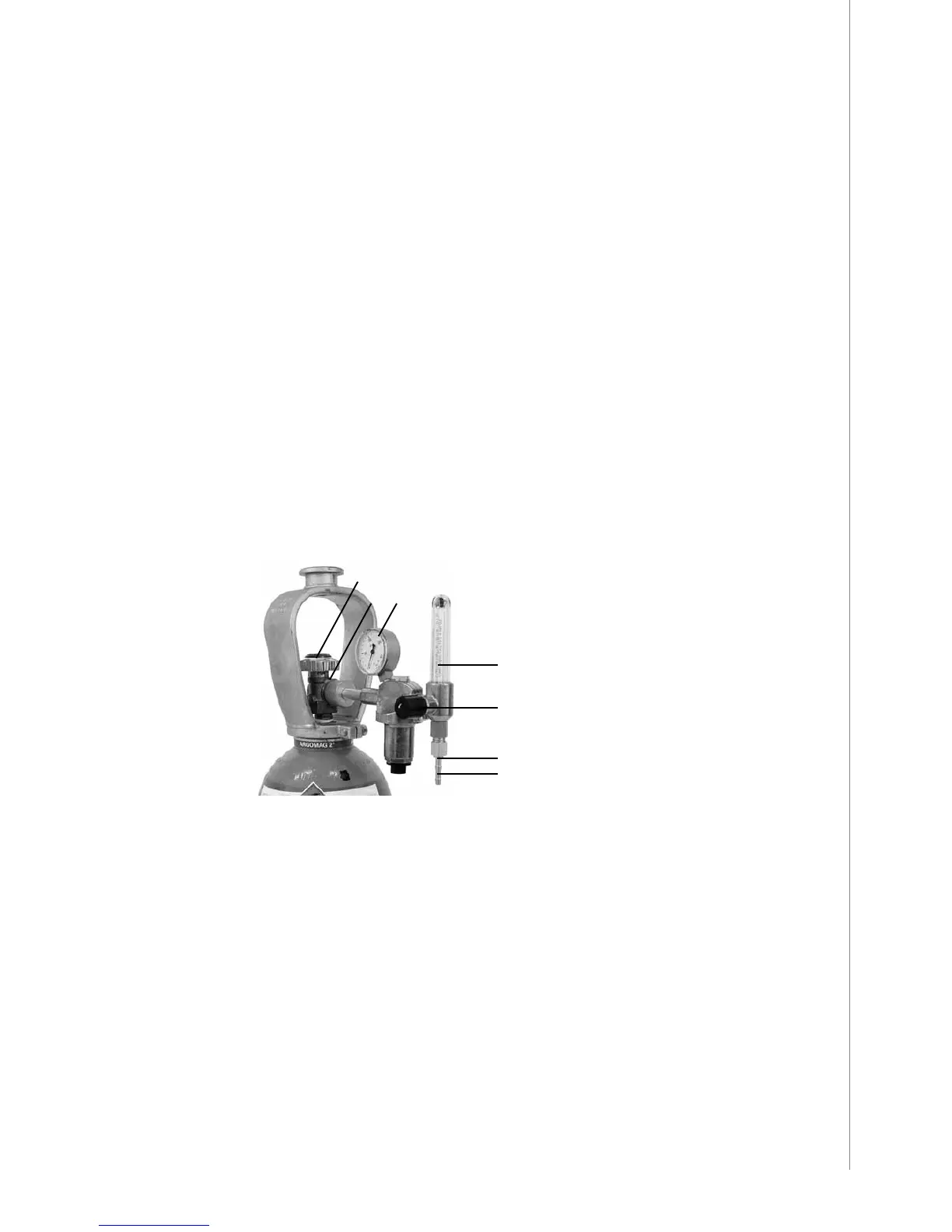

Gas ow regulator

Gas ow regulator should be suitable for shielding gas used by you. The regulator being in

your use might be dierent from the one in picture, however, following general instructions

are valid for all pressure regulators.

Before mounting of ow regulator

1. Step aside and open the bottle valve (A) for a while to blow out possible impurities from

the bottle valve.

2. Turn the press regulation screw (B) of the regulator until no spring pressure can be felt.

3. Close needle valve, if there is one in the regulator.

4. Install the regulator on bottle valve and tighten connecting nut (C) with a wrench.

5. Install hose spindle (D) and jacket nut (E) into gas hose and tighten with hose clamp.

6. Connect the hose with the regulator and the other end with the power source. Tighten

the jacket nut.

7. Open bottle valve slowly. Gas bottle pressure meter (F) shows the bottle pressure. Note!

Do not use the whole contents of the bottle. The bottle should be lled when the bottle

pressure is 2 bar.

8. Open needle valve if there is one in the regulator.

9. Turn regulation screw (B) until hose pressure meter (G) shows the required ow (or

pressure). When regulating ow amount, the power source should be switched on and

gas test button on the panel pressed simultaniously.

Close bottle valve after having nished welding. If the machine will be out of use for a long

time, unscrew the pressure regulation screw.

E

B

D

C

A

F

G

A. Gas bottle valve

B. Pressure regulation screw

C. Connecting nut

D. Hose spindle

E. Jacket nut

F. Gas bottle pressure meter

G. Gas hose pressure meter

NOTE! The gas bottle may explode if it falls!

Always fasten gas bottle tightly in vertical position, to wall stand or bottle cart, specially designed

for it! For safety reasons always remove gas bottle from transport stand of the machine before

lifting or car transport of machine!

11

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

Loading...

Loading...