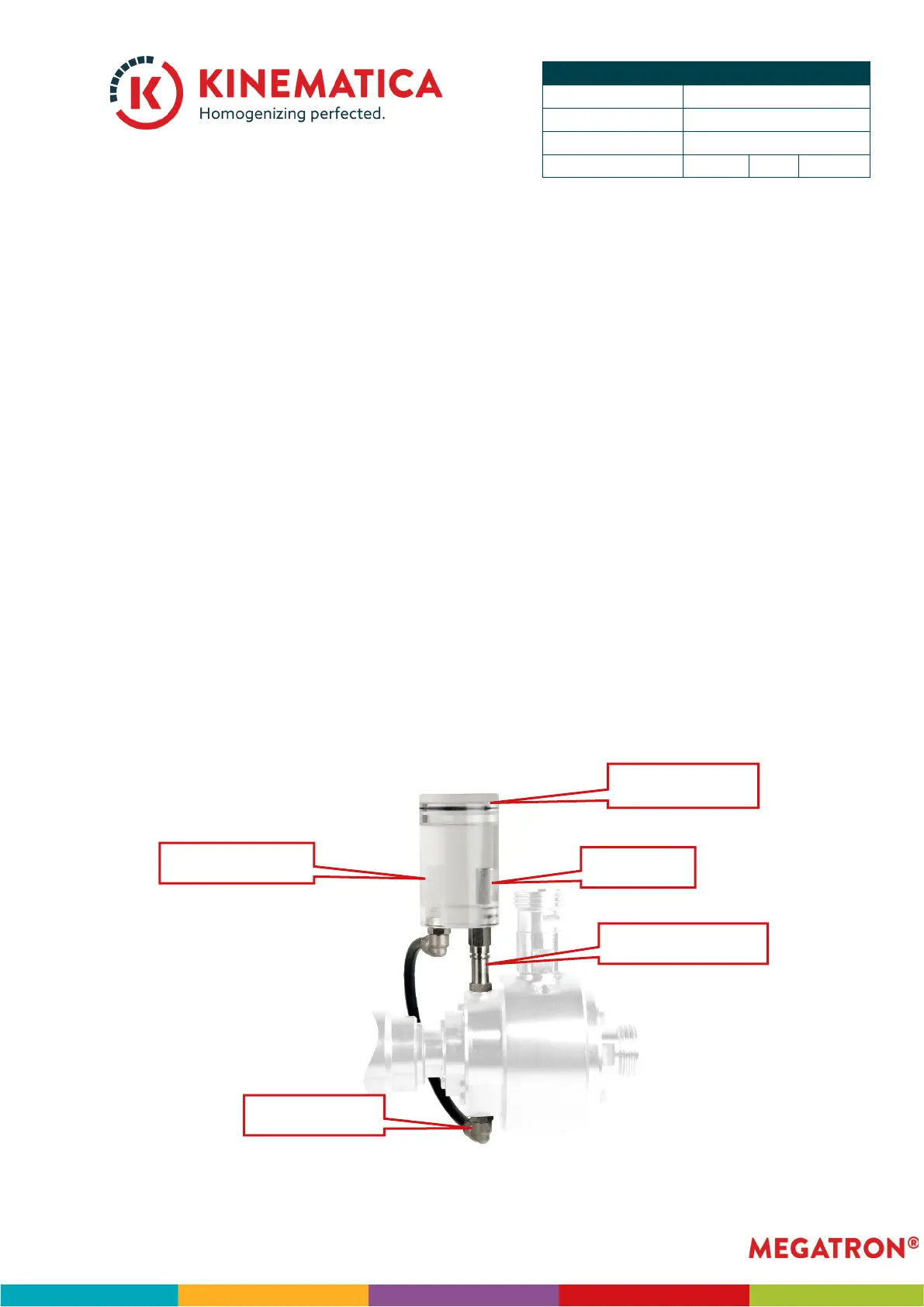

2.2.2

MECHANICAL SEAL

The product side of the working chamber (inner chamber with dispersing generator)

has to be separated from the non-product or atmospheric side of the working cham-

ber. For that purpose, a single mechanical seal is installed inside the working cham-

ber.

The type and material combination of the mechanical seal has been chosen for the

application described in the contract and should therefore not be used for other pur-

poses without the permission of the manufacturer.

A mechanical seal is not allowed to run dry. Moreover, it has always to be lubricated,

flushed and cooled by a suitable sealing lubricant. The lubricant must also be com-

patible with the product and the materials of construction. The lubricant tempera-

ture has always to be 40°C below the boiling point to prevent any damages to the

sealing system.

In the case of a single mechanical seal, a pressureless quench liquid system (flow

through or pressureless tank) is used.

The standard working chambers for the MEGATRON

®

MT 3100 S² are equipped with a

KINEMATICA quench system TS1 (also available with vessel made of PTFE)

Vessel Cover

Loading...

Loading...