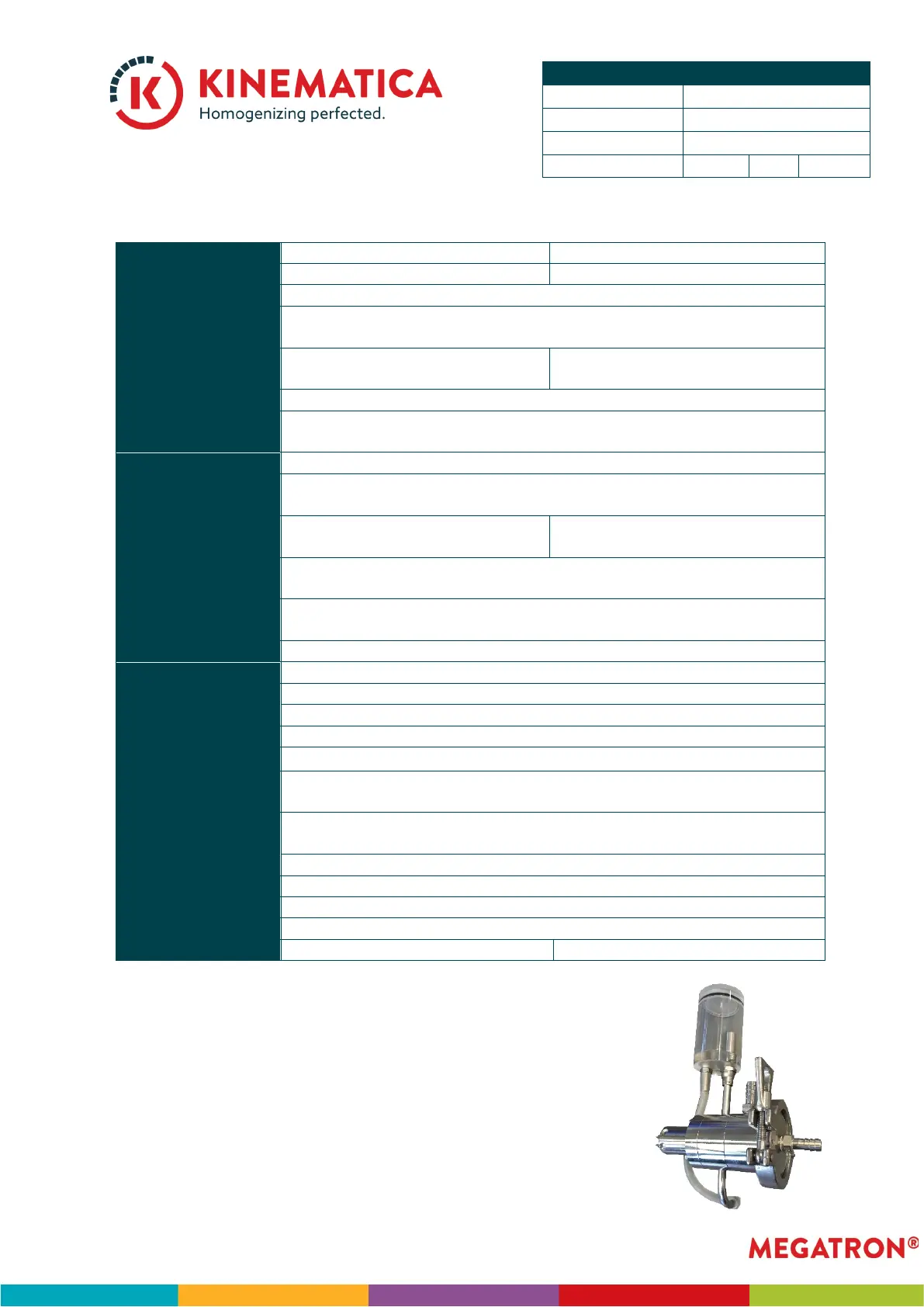

7.2 WORKING CHAMBERS

1 (for one dispersing generator)

G1/4” / Tube olive fittings Ø12/8

No Yes, connections 2xG1/8”

Temperature

max. 90°C

max. 2 bar(g) between product inlet-outlet

N/A Max. 4 bar (g)

Type 2031-010 QBV-G

Q=Silicon-Carbide / B=Carbon / V=Viton / G=Stainless Steel

tions

Yes, tube Ø8x1 / G1/8”

Yes, Standard TS1, made from Plexiglas, incl. lid and seal

Pressureless (continuous or with quench vessel)

by the product

O-Rings/Gaskets made of Viton

Product wetted parts Ra ≤ 1.6 µm

ments

The product must be pumpable and must not contain solid particles

that may destroy the mechanical seal

Viscosity

Depending on the temperature, pressure and products properties,

the dynamic viscosity should not exceed:

Other versions incl. autoclavable design available on request.

Loading...

Loading...