• Unfasten the screws (32) and remove the chamber (8). The static ring of the

mechanical seal (20.1) will come off with the chamber. Take care of the spring

(20.3).

• Remove the seal housing (2). Take care of the mechanical seal disc (6) and the

shaft seal (16).

• Unfasten the crown coupling (5).

• Push the shaft (1) with ball bearings (Pos. 13, 14) out of the bearing housing (3)

into direction of the generator.

• If necessary, remove the locking ring (18) and the compensation disc (15) from

the bearing housing (1).

• Remove the locking ring (Pos. 17) and pull off the centrifugal disc (7) as well as

the ball bearings (13,14) from the shaft.

• Mount the new ball bearings on the shaft and dispose the used ones (do not re-

install pulled off ball bearings).

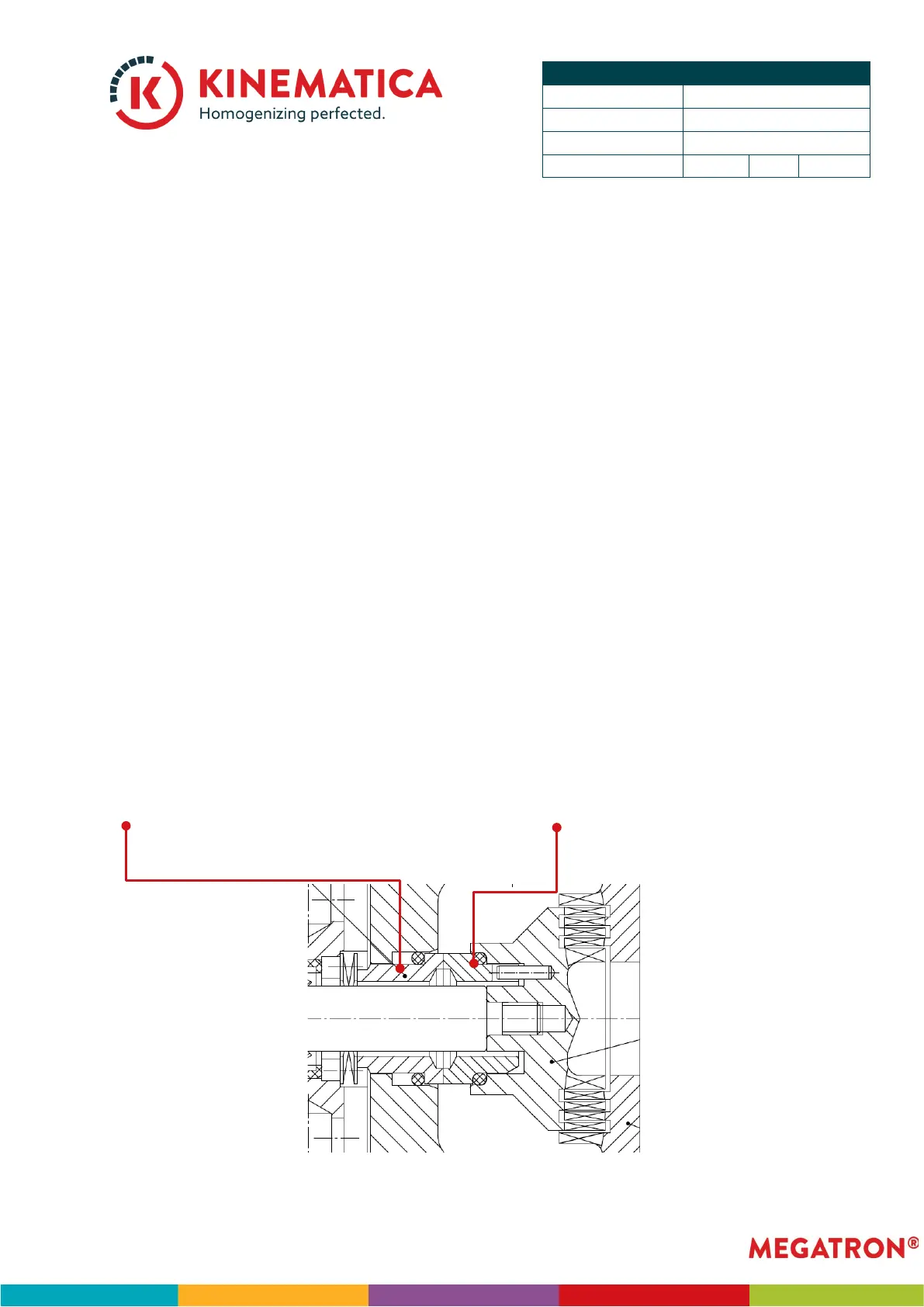

4.2.1

REPLACEMENT OF THE MECHANICAL SEAL

When mounting the mechanical seal (20), assure that the spring is in the correct po-

sition. Assure that the slide areas of the mechanical seal are clean and do not contain

any hard solid particles – solid particles in the slide areas may cause break down of

the mechanical seal.

Mechanical seals have to be replaced as a complete set. Replacing just the static or

the rotating face of the mechanical seal leads to strong and fast wear of the sliding

faces.

mechanical seal

mechanical seal

Loading...

Loading...