9

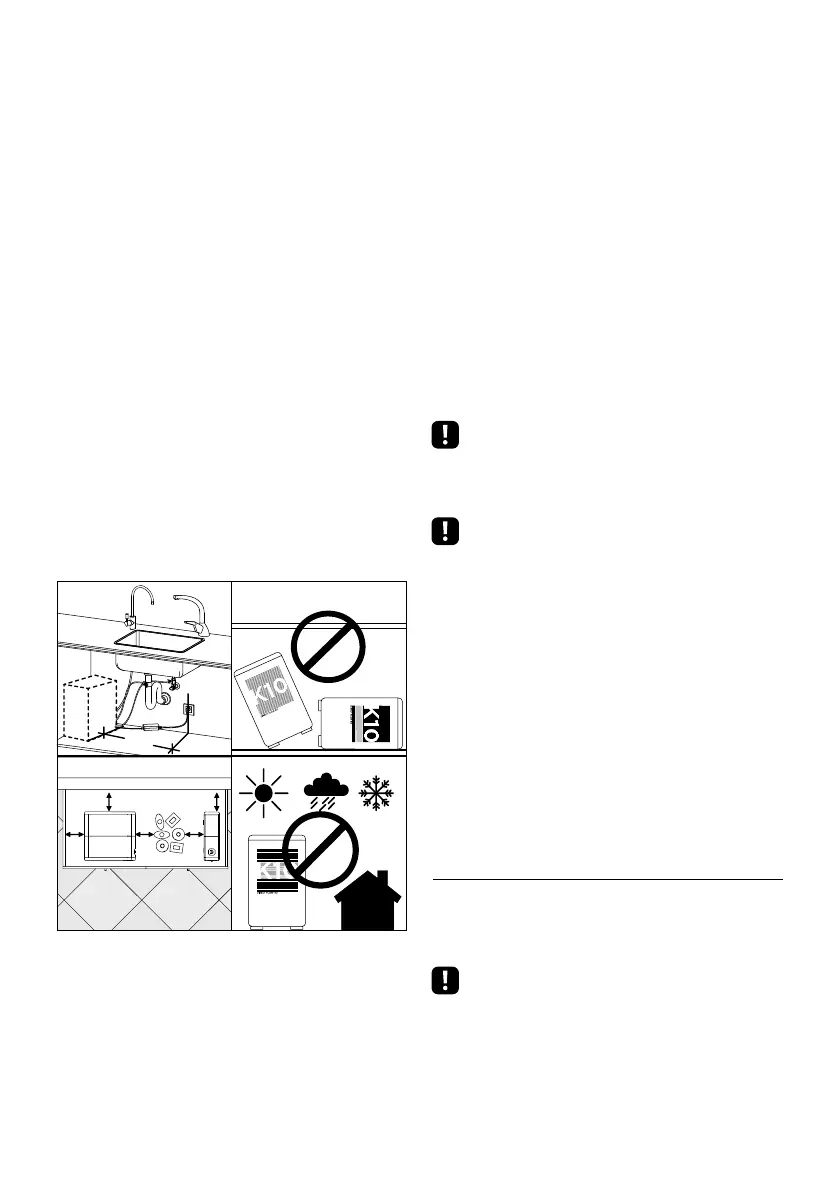

• This equipment should not be installed laying down or at an-

gle (2), as the leakage detector would become disabled.

When filled, the equipment weighs more and the dis-

tribution of weight in an unforeseen posiont may lead

some connection elements to be forced, and may thus

lead the equipment to malfunction, its components to

be damaged or loss of water.

• The spot designated for its installation must be large

enough to host the device, its accessories, connections

and to allow for maintenance to be carried out com-

fortably (3).

• The equipment should never be installed outdoors (4).

• The environment and room where equipment and tap are

installed must maintain adequate hygienic-sanitary condi-

tions.

•Avoid external drips on the equipment, coming from

pipes, drains, etc.

ATTENTION: The equipment must not be installed

next to a heat source or should not receive any

direct hot air over them.

2.3. START UP AND MAINTENANCE

ATTENTION: Water treatment equipment needs

periodic maintenance carried out by qualified te-

chnical personnel, in order to guarantee the quality of

water produced and supplied.

• Consumables must be replaced with the frequency

indicated by the manufacturer.

• The equipment must be sanitized periodically and

prior to start-up.

• After commissioning, discard the water produced du-

ring the first 10 minutes of use.

• Maintenance must be carried out by qualified tech-

nical personnel, with adequate attitude and hygienic

conditions, in order to reduce the risk of internal con-

tamination of the device and its hydraulic system. (For

more information contact the technical service of your

distributor).

3. UNPACKING

It is important that before you install and start-up the

equipment, you revise the materials received in order

to guarantee that they have not been damaged during

transportation.

ATTENTION: Any claim for damages suffered du-

ring transportation must be presented together

with the delivery note or invoice to your distri-

butor, noting the name of the carrier, within 24 hours

from receiving the merchandise.

Take out the equipment and accessories from their

cardboard packaging, removing the corresponding pro-

tections.

• We recommend that the water to be treated be de-

calcified or of a maximum hardness of 15 HF so as to

obtain the best performance from the equipment.

• If the water to be treated is harder than 15 HF, the

longevity of the membrane and the performance of the

equipment may be reduced.

• If the water supplied contains a total chlorine con-

centration greater than 1.2 ppm, we recommend the

installation of an active carbon dechlorination filter

to reduce the concentration of chlorine in the water

and thus protect and extend the life of the equipment’s

components.

If the water to be trated contains:

High concentrations of iron and magnesium

(Higher than 1 ppm when measured in the wa

ter that the machine rejected).

Extended periods of hyper-chlorination.

Sludge and cloudiness higher than 3 NTU.

Nitrate concentration higher than 100 ppm.

Sulphate concentration higher than 250 ppm.

• Get in touch with your distributor so that they can re-

commend you the most appropriate treatment for your

case so as to ensure the correct operation of the equi-

pment and thus avoid any damages to the components

and guarantee the quality of the water provided.

2.2 LOCATION OF THE EQUIPMENT

• If you need to adapt the facilities of your residence or

business in order to be able to install the equipment in

the designated space, any adaptation should be done

following all applicable national regulations concerning

the internal installation of water and power supplies.

• This equipment requires that a power outlet be placed

at least one meter away (1).

1

1 m

3

2

4

Loading...

Loading...