A. Daily checkings

Everiday, a visual checking of the machine is necessary in order to turn up and anticipate any flaw

before they become serious. A particular care should be given to the following details:

Hydraulic leakages: Shown by hydraulic oil spilled on or under the vehicle, on its floor or in

the boom.

Tires : Prospective damages, properly inflated

Hydraulic oil level

In winter, Take care about making a freeze protection or adding antifreeze liquids.

Bucket : Check that the bucket has no cracks or damages on its side and also on its bottom.

In case of If a problem turns up, the bucket must be repaired by a qualified operator before

any use.

Hydraulic pipes : Check for cracks and any damage.

Electric wires : Check for cracks and any damages.

Elevator boom : Battered, scratched paint.

Hydraulic outriggers pads (optional) : Check for damages

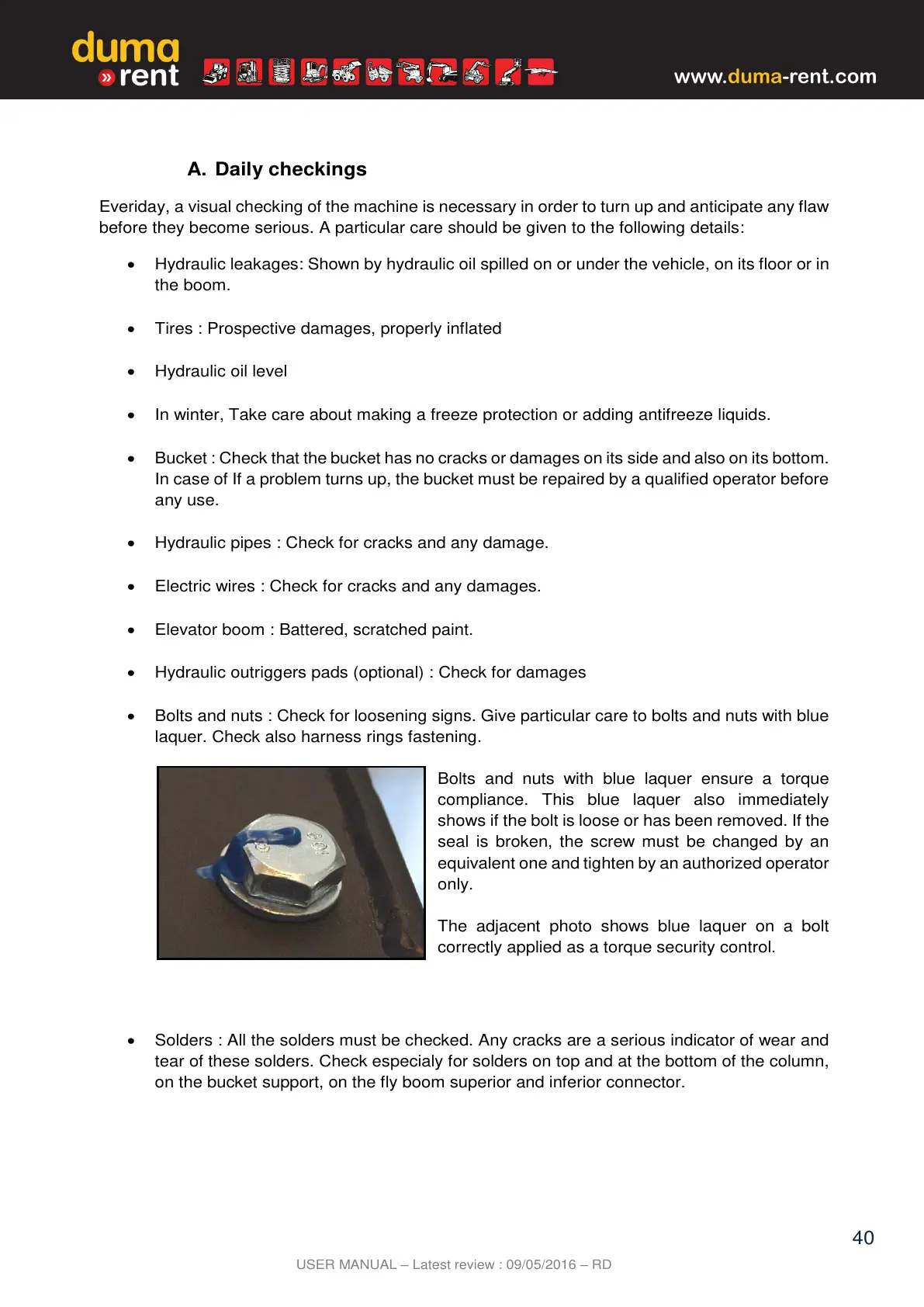

Bolts and nuts : Check for loosening signs. Give particular care to bolts and nuts with blue

laquer. Check also harness rings fastening.

Bolts and nuts with blue laquer ensure a torque

compliance. This blue laquer also immediately

shows if the bolt is loose or has been removed. If the

seal is broken, the screw must be changed by an

equivalent one and tighten by an authorized operator

only.

The adjacent photo shows blue laquer on a bolt

correctly applied as a torque security control.

Solders : All the solders must be checked. Any cracks are a serious indicator of wear and

tear of these solders. Check especialy for solders on top and at the bottom of the column,

on the bucket support, on the fly boom superior and inferior connector.

Loading...

Loading...