F. Hydraulic oils / filters

The elevator is supplied with hydraulic oil (TITAN FUCH H32 oil). This oil is made for use in

« temperate climates » in standards temperatures. H46 oil is also suitable but its compulsory to

use a HV type oil

The oil filter must be changed the first 30 days of use and then after 1 year or 500h of use

(whichever comes first).

Pump cavitation and noisy operation are due to a clogged filter, a low oil level or too cold outside

temperature for the oil type.

To change the oil filter, unscrew the filter block and change it by a new one. Take care to lightly

oil the gasket.

G. Greassings

Slew ring

The slew ring is supplied correctly lubricated.

- Used grease : VANGUARD SILEX PLS/3

- Operating temperature : -35/+130°C

Compliant greases :

- TOTAL CALORIS M/3

- FINA BENTEX 5M

- SHELL RETINAX HDX

- MOBIL MOBILGREASE SPECIAL

- FUCHS RENOLIT FLM/2

- BP GREASE LTX/2M

- AGIP GREASE SM/2

- CASTROL MOLY GREASE/2

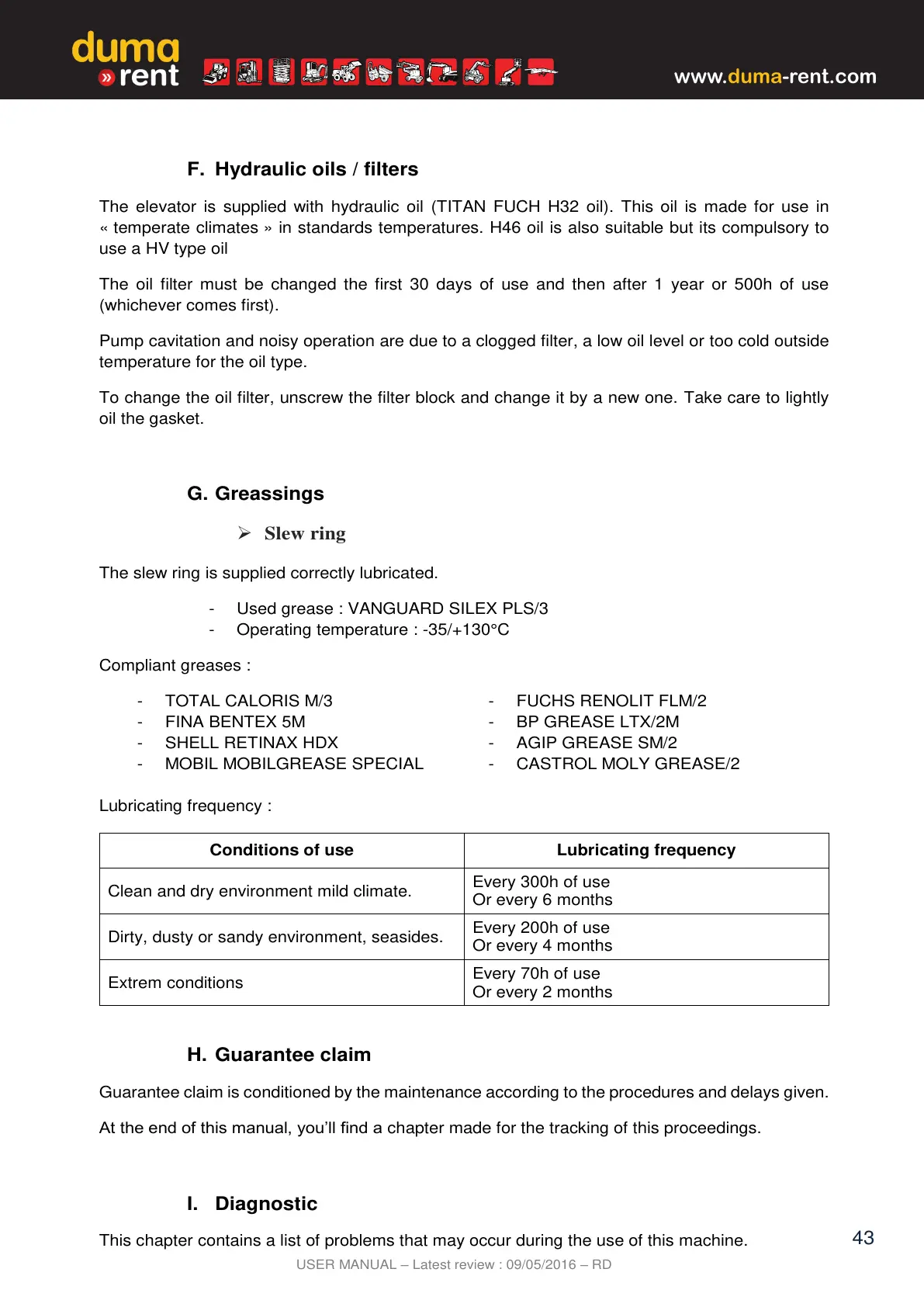

Lubricating frequency :

H. Guarantee claim

Guarantee claim is conditioned by the maintenance according to the procedures and delays given.

At the end of this manual, you’ll find a chapter made for the tracking of this proceedings.

I. Diagnostic

This chapter contains a list of problems that may occur during the use of this machine.

Loading...

Loading...