1.3

Section 1

Safety and General Information

1

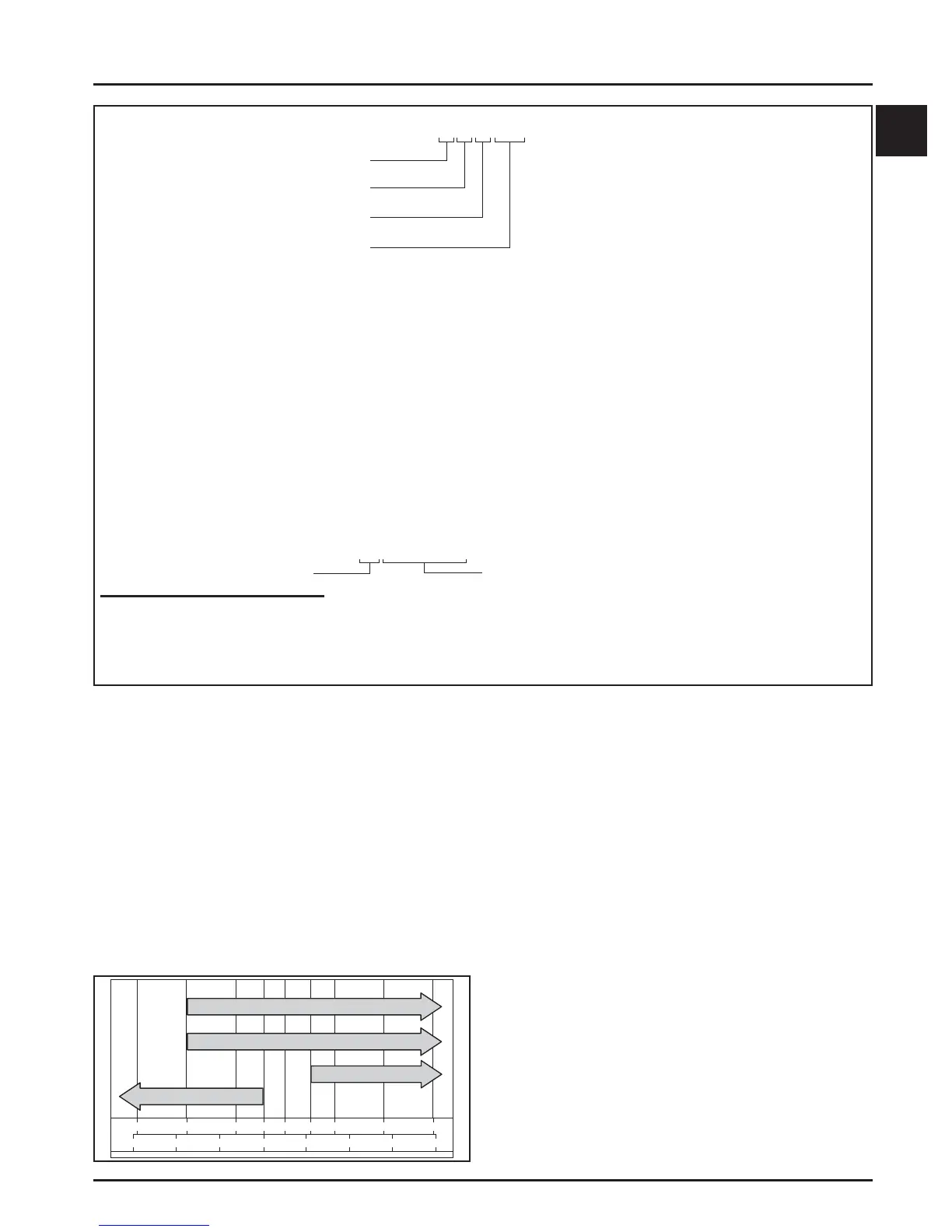

Figure 1-2. Explanation of Engine Identifi cation Numbers.

A. Model No.

Electronic Fuel Injection (EFI)

Command Engine

Numerical Designation

630

650

680

730

740

749

B. Spec. No.

ECV630-XXXX

ECV650-XXXX

ECV680-XXXX

ECV730-XXXX

ECV740-XXXX

ECV749-XXXX

C. Serial No.

Year Manufactured Code

Code Year

39 2009

40 2010

41 2011

Factory Code

39 05810334

E C V 749

Vertical Crankshaft

Oil Recommendations

Using the proper type and weight of oil in the

crankcase is extremely important. So is checking oil

daily and changing oil regularly. Failure to use the

correct oil, or using dirty oil, causes premature engine

wear and failure.

Oil Type

Use high-quality detergent oil of API (American

Petroleum Institute) Service Class SJ or higher. Select

the viscosity based on the air temperature at the time

of operation as shown in the following table.

NOTE: Using other than service class SJ or higher oil

or extending oil change intervals longer than

recommended can cause engine damage.

NOTE: Synthetic oils meeting the listed

classifi cations may be used with oil changes

performed at the recommended intervals.

However, to allow piston rings to properly

seat, a new or rebuilt engine should be

operated for at least 50 hours using standard

petroleum based oil before switching to

synthetic oil.

°F

-20

020324060

50 80 100

°C

-30 -20

-10 0

10 20 30

40

5W-30

10W-30

Kohler 10W-30

SAE 30