TP-6126 8/0248 Section 6 Accessories

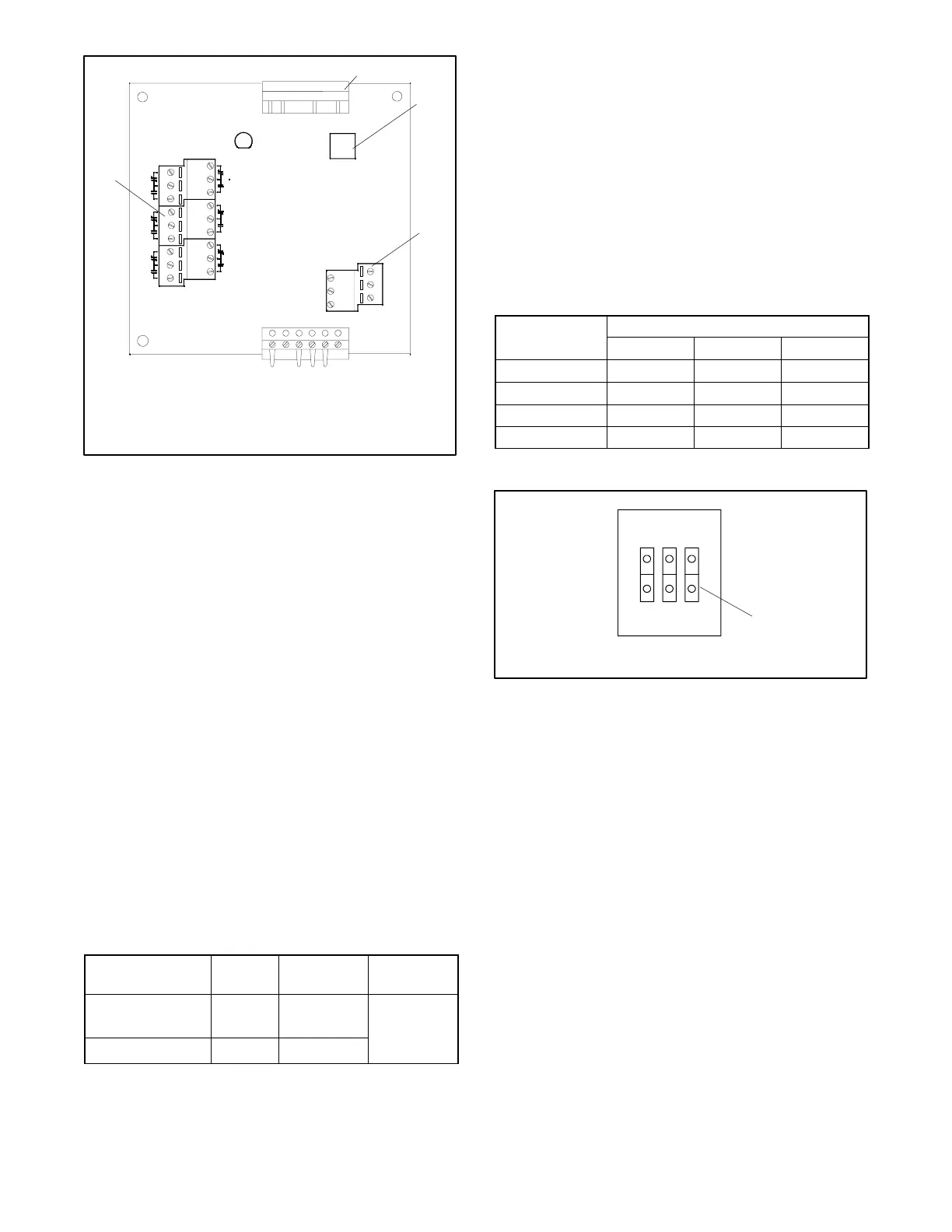

gm21115a

1. Controller harness connection

2. Address DIP switches

3. Input connections

4. Output connections

3

4

TB2

1

6

P2

-- -- O P E N -- --

321

DIAGNOSTIC

SW1

IN1+

IN1--

DIGITAL

IN2+

IN2--

RDO1 RDO2 RDO3

RDO5 RDO6

RDO4

RELAY OUTPUT

INPUT

LED1

6

P1

TB1

1

2

Figure 6 -14 I/O Module Input and Output

Connections

I/O Module Connection Procedure

1. Disconnect power to the transfer switch before

connecting to the I/O modules.

2. Remove the I/O module cover and connect devices

to the I/O module input terminals on terminal block

TB1 or output terminals on terminal block TB2. See

Figure 6-14 for the terminla block locations. The

output connections on the I/O module are labelled

RDO (relay driver output) 1 through 6. Use wire

sizes within the specifications in Figure 6-15 for the

input and output connections.

3. Tighten the connections to 0.5 Nm (4.4 in. lb.).

4. Record the connections on the label on the cover

and replace the cover.

5. Use the Setup Program to set up the I/O board

communications and to define the I/O board inputs

and outputs. Refer to the Setup Program

Operation Manual for instructions.

Component

Number

of Wires

Wire Size

Range

Tightening

Torque

Controller terminal

strip I/O terminals

1 #12--24 AWG

0.5 Nm

I/O board terminals 1 #14--26 AWG

4.4 in. lb.)

Figure 6 -15 Input and Output Connection

Specifications

6.5.3 I/O Module Address

Each I/O Module requires a unique address.

Factory-installed I/O module addresses are set at the

factory.

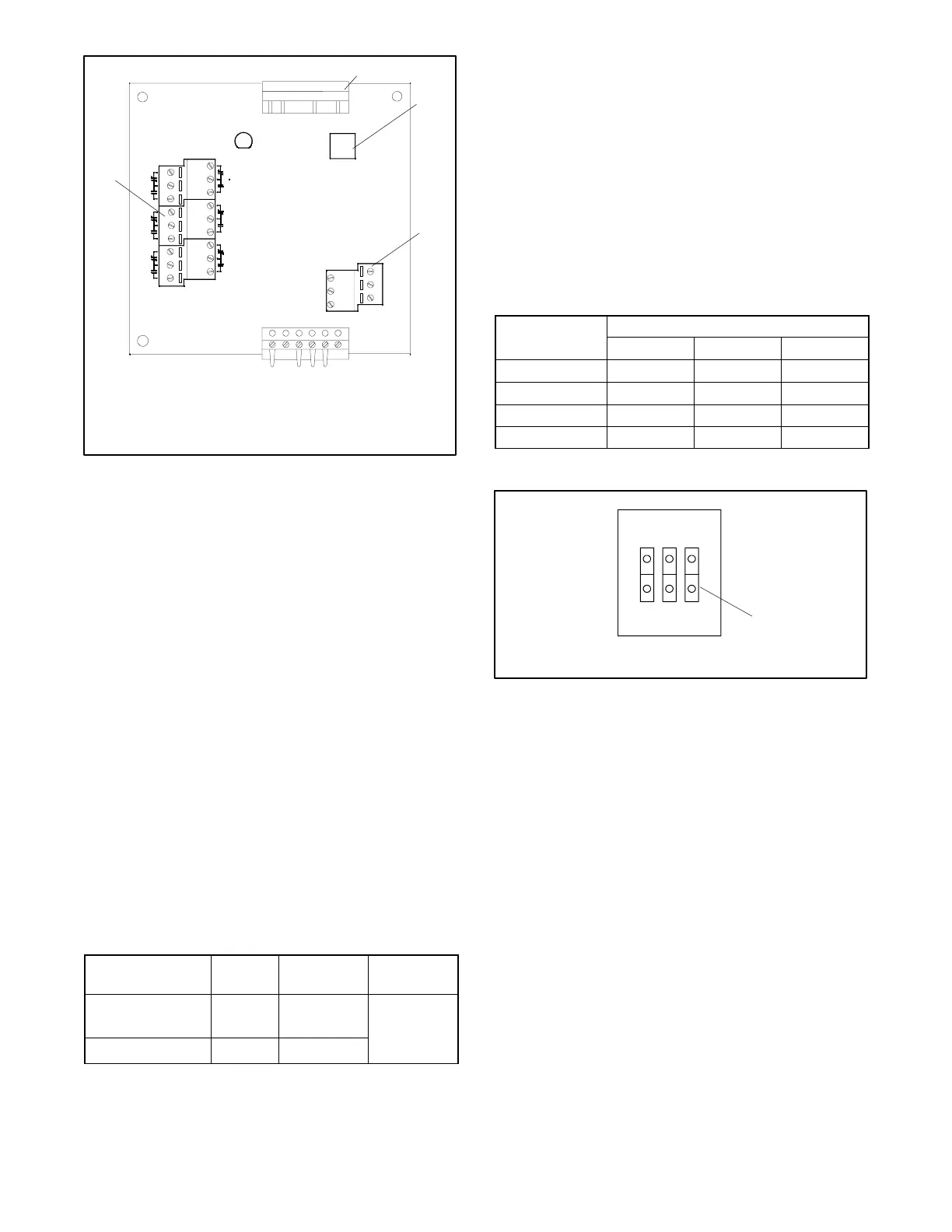

To check the I/O module addresses, compare the DIP

switch settings with Figure 6-16, starting with the

module connected to the controller harness.

Figure 6-14 shows the address DIP switch location on

the I/O module. Push down the end of the DIP switch

near the OPEN label to open the switch, or push down

the other end to close it. See Figure 6-17.

Address DIP Switches

Number

1 2 3

1 Closed Closed Closed

2 Closed Closed Open

3 Closed Open Closed

4 Closed Open Open

Figure 6 -16 I/O Module Address DIP Switches

1

6126

1. Push this side down to open.

OPEN

123

Figure 6 -17 I/O Module Address DIP Switches

6.5.4 I/O Module Faults and Diagnostics

When power is applied to the system, the controller

attempts to initiate communication with each connected

I/O board. The following faults may occur on powerup if

the I/O modules are not correctly installed, addressed,

or configured in the setup software. Check the LED on

each I/O module for diagnostic information in the case of

a fault.

Diagnostic LED. Each I/O module has a diagnostic

LED that lights or flashes to indicate the I/O board status

as described in the table in Figure 6-18.

I/O Module Not Found. If the system does not detect

an I/O module at an expected address, the Service

Required LED flashes and the software logs the

message, “I/O Module Not Found”. Check that the

number of I/O modules installed matches the number

expected by the setup program. Check that the I/O

Loading...

Loading...