Vers. 111219 Page 27

SERIAL PRINT:

Every control unit is supplied with a 9 pin serial female connector (connection pin: PIN 2 = TX, PIN 3 =

RX, PIN 5 = GND) and a mini USB connector. You can print the results of each screwing on a printer (for

example Kolver model PRNTR1) and/or on PC (for example through Hyper Terminal or Realterm or any

data transmission program or EDU EXPAND only on EDU2AE/TOP ver. 3.00 – only print not setting). You

can also save those results on a USB device (only on EDU2AE/TOP/E and EDU2AE/TOP/TA from ver.

3.00). The transmission characteristics (only serial and USB) are the following: 9600 (bits per second), 8

(data bits), n (no parity), 1 (bits stop 1).

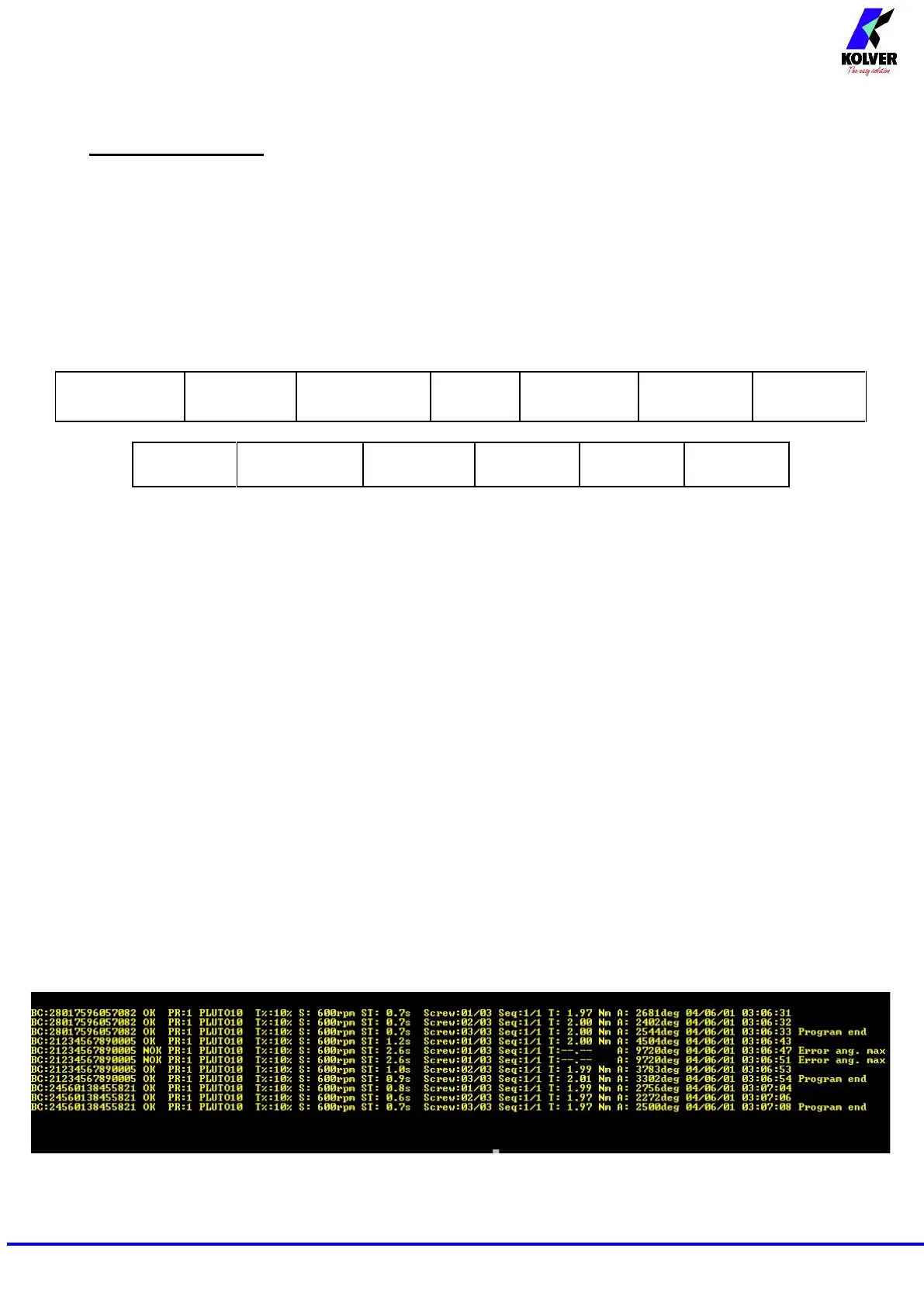

The print string is the following:

BC: Barcode = it begins with “BC:” and it’s followed by the code of the scanned product.

Result = screwing result: correct or incorrect.

OK = the torque has been correctly reached, all the selected parameters are satisfied and the control

unit will give out a beep sound of 0.5 sec.

NOK = the torque has been reached during ramp time or Fast Speed (see error table). In this

case, the unit will give out 2 beep sounds and the red led will light up.

PR: Program number = it indicates the running program.

Model = Model of screwdriver you’re using.

T%: Torque% = percentage of the set torque level.

S: Speed = preset speed value.

ST: Screwing time = it indicates the time of the screwing.

Screw: Number of screws = number of tightened screws/total number of screws.

Seq: Sequence stage = it indicates the stage of the sequence.

T: Torque = torque value.

A: Angle = angle value.

Notice = in case of program end, it prints “Program End”, in case of sequence end, it prints “Seq. end” or it

indicates the type of error (see paragraph: trouble shooting).

Loading...

Loading...