11 Maintenance

11.1 Required maintenance

Requirement:

ü The ambient conditions correspond to the operating data

ü Flowmeter connection to the pipe system is stress-free

ü Pipe system is free of solid particles

ü Pipe system vented

ü Shut-off devices in the feed line and outlet opened

Switch on the system.

ð The flowmeter is ready to operate.

11 Maintenance

11.1 Required maintenance

Flowmeters are fundamentally maintenance-free. Under observance of the operating limits Ä Tech-

nical data,Page8, no significant change in the characteristics could be established, even after years of

use in many cases. Stresses lying clearly above the rated flow rate can, however, result in excessive

wear. In the case of liquids with higher abrasiveness (for example heavy fuel oil with catalyst residues,

plastic components with fillers, etc.) strongly accelerated wear can occur in the flowmeter.

Notice In cases of doubt the manufacturer recommends already carrying out the first inspection after twelve

weeks operation time.

11.2 Maintaining flowmeters

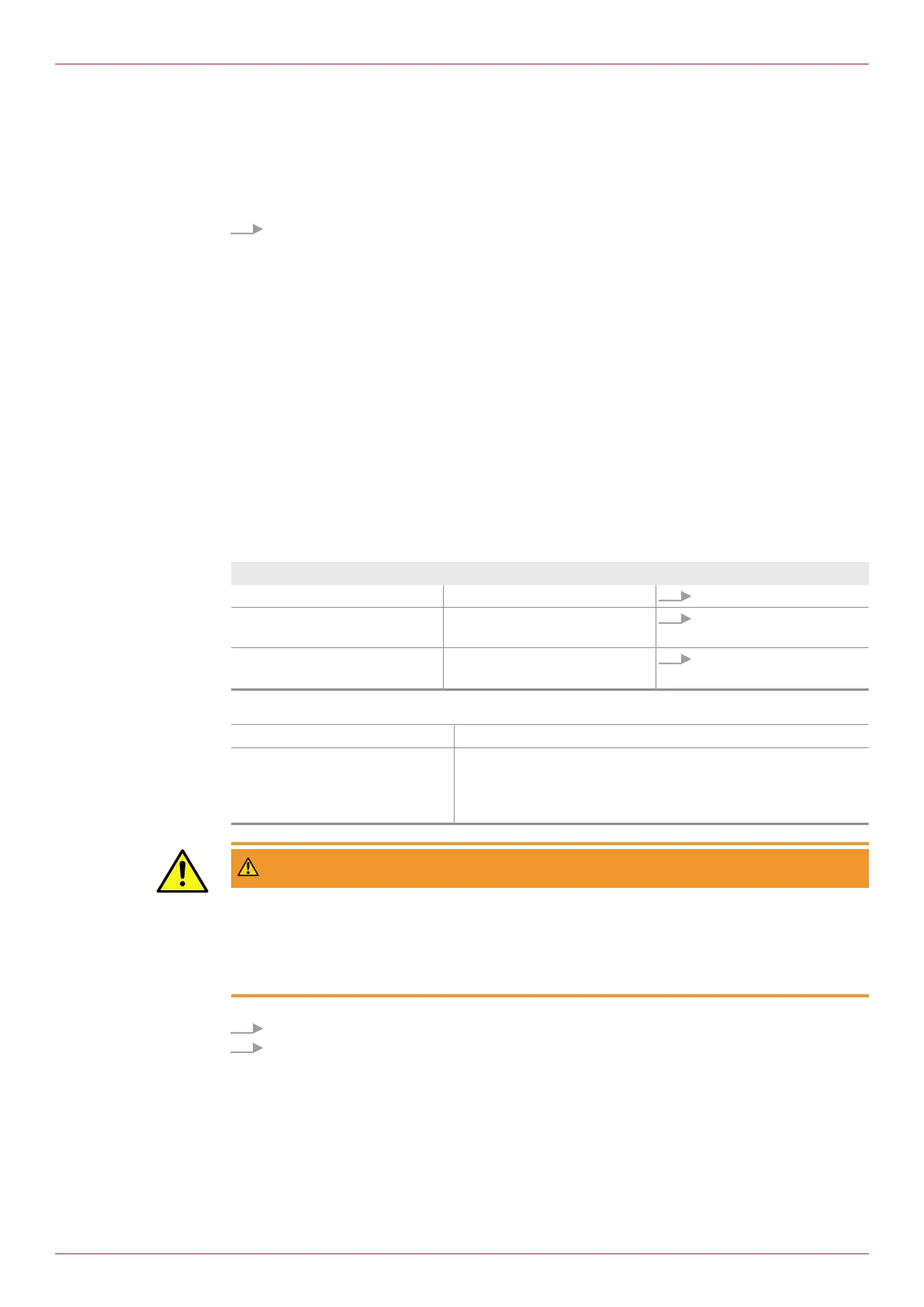

The following table lists signs of progressive wear of individual elements of the flowmeter:

Finding Cause Elimination

Increased running noises Incipient damage to bearing

Replace the bearing.

Leakage Damage to sealing

Replace the seals or dry

sleeve.

Measured values not realistic Ä Troubleshooting,Page42

Ä Troubleshoot-

ing,Page42

Tab.10: Check table for required maintenance

Personnel qualification: o Fitter

Personal protective equipment: o Work clothing

o Face protection

o Protective gloves

o Safety boots

WARNING

Risk of injury through emitted pumped liquid.

Pumped liquids can be hot, poisonous, combustible and caustic.

► Wear personal protective clothing during all the work. Ensure face protection.

► Collect any discharging pumped liquid safely and dispose of it in an environmentally compatible

manner in accordance with the applicable local regulations.

1. Check the flowmeter visually and acoustically every four weeks.

2. Check for signs of wear as listed in the table above and eliminate the cause.

11.3 Recalibration of the flowmeter

In order to maintain the high measuring precision of the flowmeter, the manufacturer recommends car-

rying out the first recalibration after about one year of operation. The results reveal any wear starting

on the measuring unit. The interval at which recalibrations are actually required depends strongly on

the operating conditions of the flowmeter.

The manufacturer provides the factory calibration as standard. If higher requirements are placed on the

flowmeter, accredited calibration in accordance with EN/ISO/IEC17025 is also possible.

Operating instructions

OIO 14en-GB Edition 2020-01

31

Loading...

Loading...