14 Troubleshooting

14.1 Possible faults

14 Troubleshooting

14.1 Possible faults

Faults can have different causes. The following tables list the symptoms of a fault, the possible causes

and measures for troubleshooting.

In the case of faults please contact the manufacturer. Under services@kral.at.

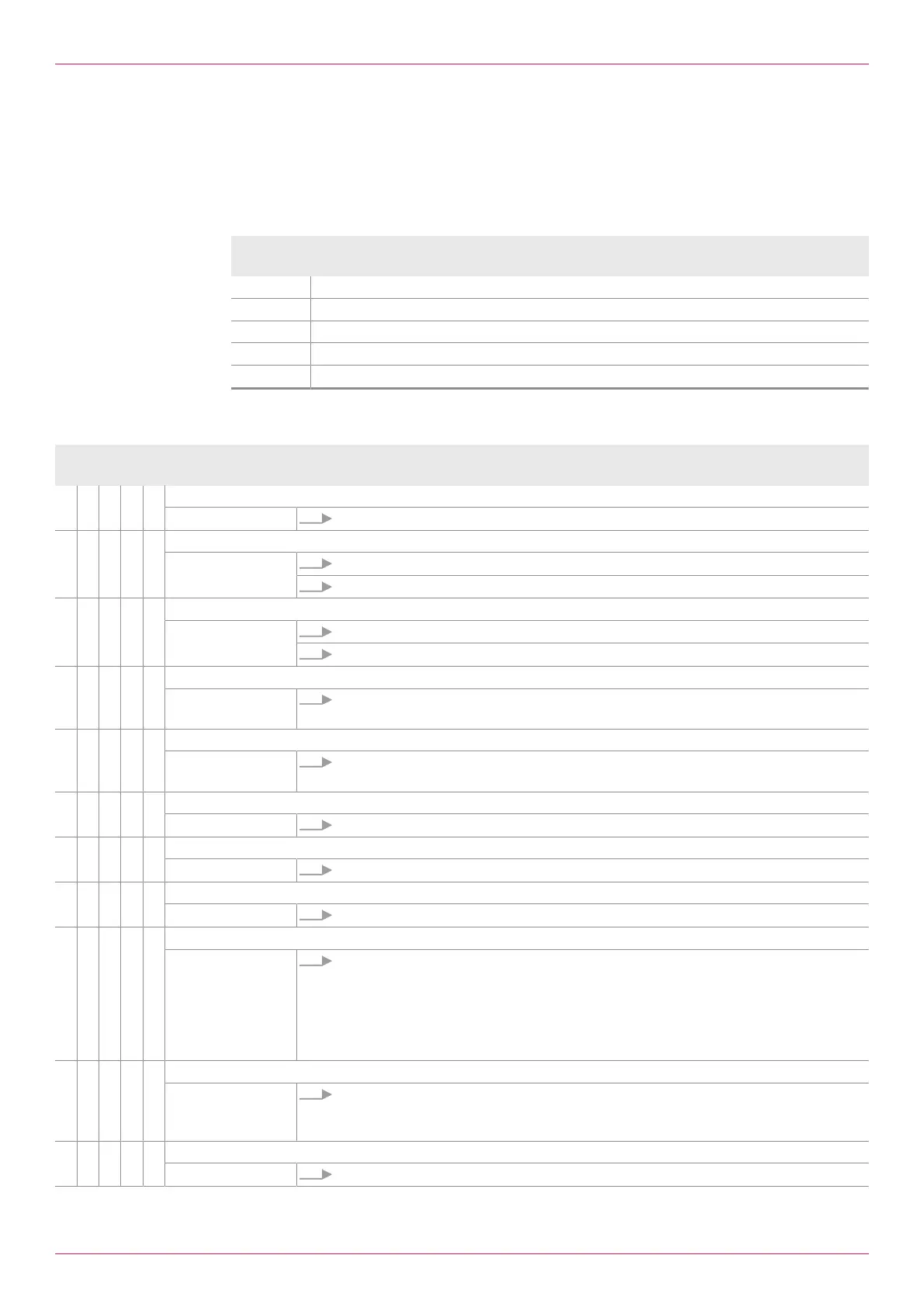

Identifica-

tion

Fault

1 Flowmeter leaks

2 No flow rate

3 Flowmeter does not generate a pulse

4 Pressure loss too high

5 Measured values not realistic

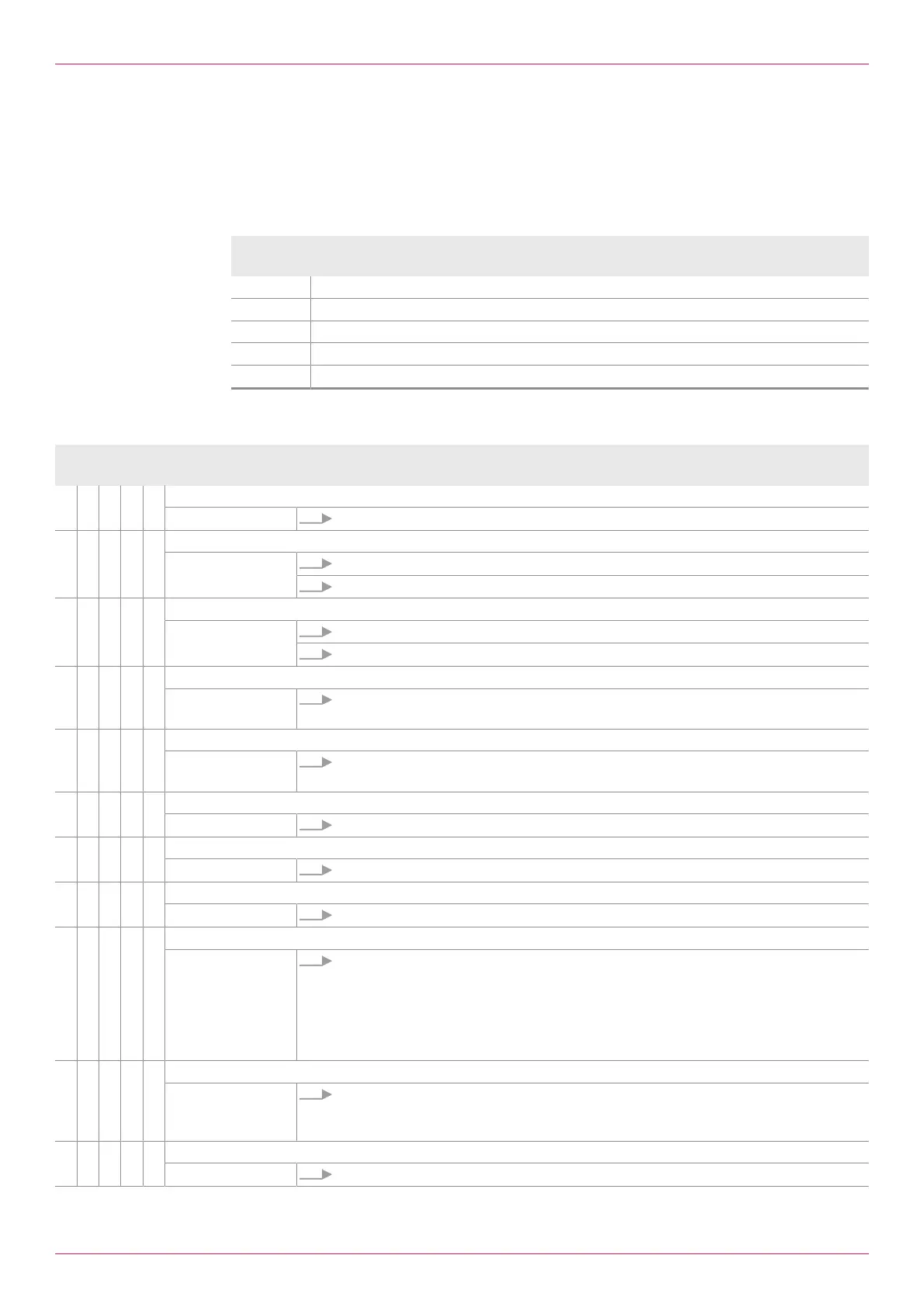

14.2 Troubleshooting

Fault identifica-

tion

Cause Remedy

1 – – – – Seal preload too low

Preload the screws.

1 – – – – Seal damaged

Replace the seal.

Check the chemical resistance of the seal.

– 2 3 – 5 Foreign particles in the liquid and/or flowmeter

Dismantle the flowmeter and clean it.

Use the commissioning filter.

– – 3 – 5 Pick up not connected correctly

Check the power supply for the pick up. In the process observe the operating instruc-

tions of the pick up.

– – 3 – 5 Pick up defective

Check the function of the pick up. In the process observe the operating instructions of

the pick up.

1 – 3 – – Dry sleeve destroyed

Replace the dry sleeve. Contact the manufacturer in the process.

– 2 3 – – Inlet pressure too low

Increase the inlet pressure.

– – – 4 – Viscosity of the liquid too high

Increase the temperature. When doing so observe the temperature range.

– – 3 – – Flow rate too low

Increase the flow rate.

-or-

Use a flowmeter with a suitable size.

-or-

Use linearization. In the process observe the operating instructions of the electronic

equipment.

– – – 4 – Flow rate too high

Reduce the flow.

-or-

Use a flowmeter with a suitable size.

– – – – 5 Airlocks

Deaerate the system and check for leaks.

42

OIO 14en-GB Edition 2020-01

Operating instructions

Loading...

Loading...