12 Servicing

12.1 Dangers during servicing

12 Servicing

12.1 Dangers during servicing

The following safety instructions must be observed strictly:

o Have all work only carried out by authorized qualified personnel.

o To ensure the measuring precision, the measuring unit may only be replaced by the manufac-

turer.

o Before beginning work, let the flowmeter cool down slowly to the ambient temperature. Avoid

rapid temperature changes.

o Pumped liquids can be hot, poisonous, combustible and caustic.

o Observe the tightening torques Ä Appendix,Page54.

o Observe the operating instructions and data sheets of the sensors.

12.2 Replacing seals and ball bearings

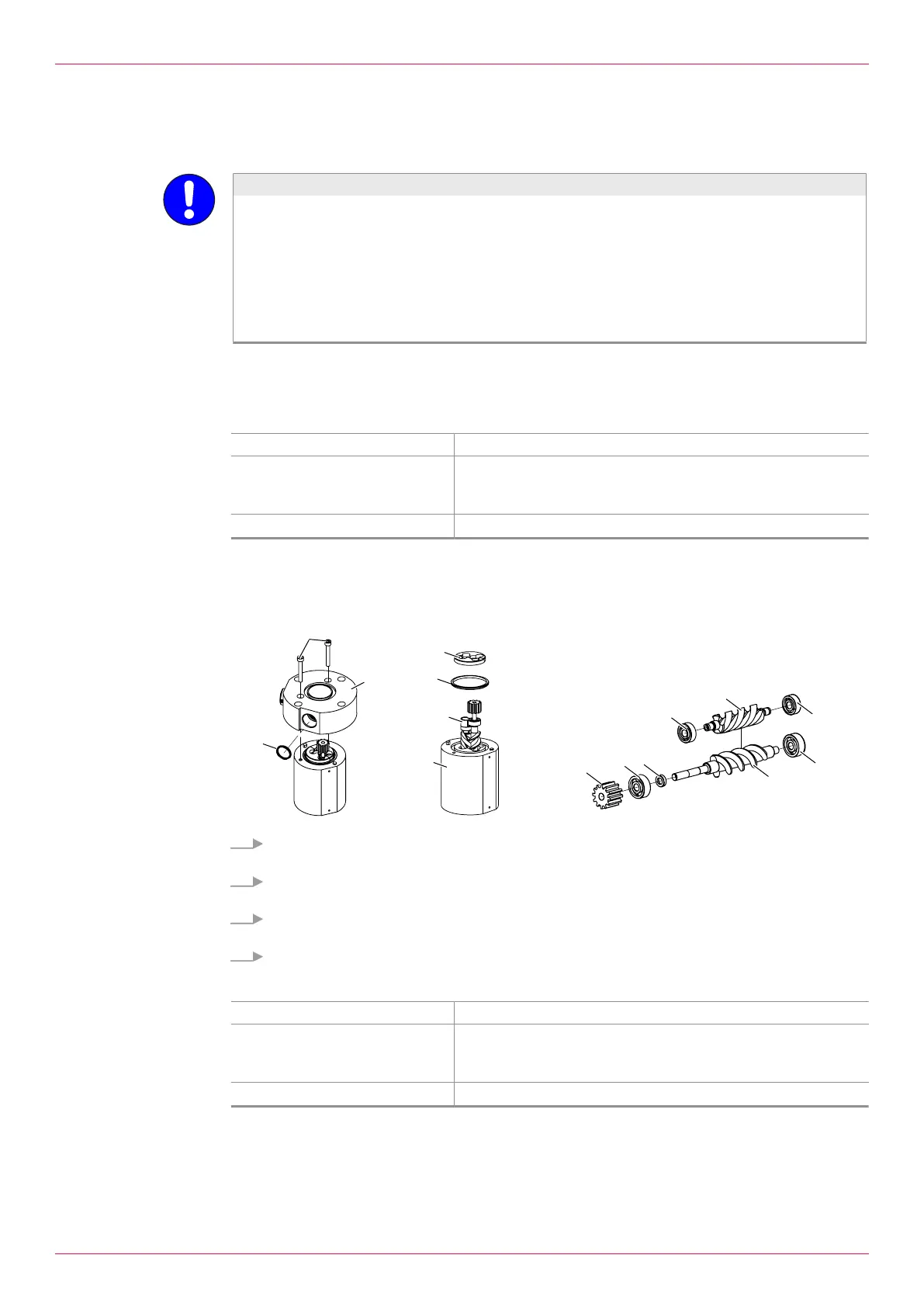

12.2.1 Removing seals and ball bearings OMG-013

Personnel qualification: o Fitter

Personal protective equipment: o Work clothing

o Protective gloves

o Safety boots

Aids: o Extractor

Requirement:

ü Flowmeter removed from system

ü Completion consisting of socket screws, flanges and seals removed

ü Pick up inserts removed

1. Remove the socket screws2, take off the bearing cover3 and O-ring1 from the pick up hole in

the bearing cover.

2. Remove the spacer 4 and O-ring5 and pull the screw set together with the distance sleeve6

from the measuring housing7.

3. Use the extractor to pull off the pole wheel8, ball bearings9 and12 from the measuring screw

large11 and remove the sleeve10.

4. Use the extractor to pull the ball bearings15 and13 from the measuring screw small14.

12.2.2 Installing seals and ball bearings OMG-013

Personnel qualification: o Fitter

Personal protective equipment: o Work clothing

o Protective gloves

o Safety boots

Aids: o Torque wrench

32

OIO 14en-GB Edition 2020-01

Operating instructions

Loading...

Loading...